- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

preform moud

-

Mould base material:

-

P20 steel

-

Mould cavity/core material:

-

S136 steel

-

Lock Way:

-

self lock

-

Runner Type:

-

hot runner

-

Gate/Tail:

-

valve gate

-

Plastic material for product:

-

PET

-

Design software::

-

UG,CAXA ect.

-

Mould warrant:

-

1 million shots

-

Lead time::

-

45 days

-

After-sales Service Provided::

-

Engineers available to service machinery overseas

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

preform mould

-

Model Number:

-

preform moud

-

Mould base material:

-

P20 steel

-

Mould cavity/core material:

-

S136 steel

-

Lock Way:

-

self lock

-

Runner Type:

-

hot runner

-

Gate/Tail:

-

valve gate

-

Plastic material for product:

-

PET

-

Design software::

-

UG,CAXA ect.

-

Mould warrant:

-

1 million shots

-

Lead time::

-

45 days

-

After-sales Service Provided::

-

Engineers available to service machinery overseas

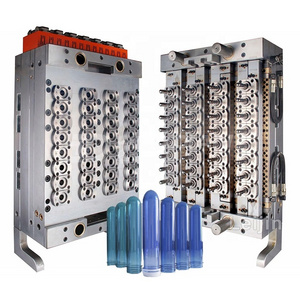

Preform design

With decades design and manufacture experience, XueJun mould designs not only preform with standard neck size for water bottle, carbonated drink bottle and oil bottle, also design preform of special shape responding to customers request. XueJun adopts a wide range of computer-aided engineering service from design conception to the finished products to make customer satisfied.

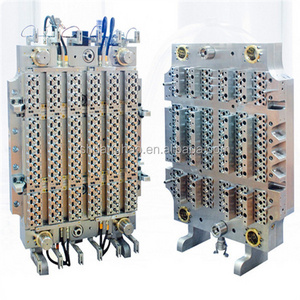

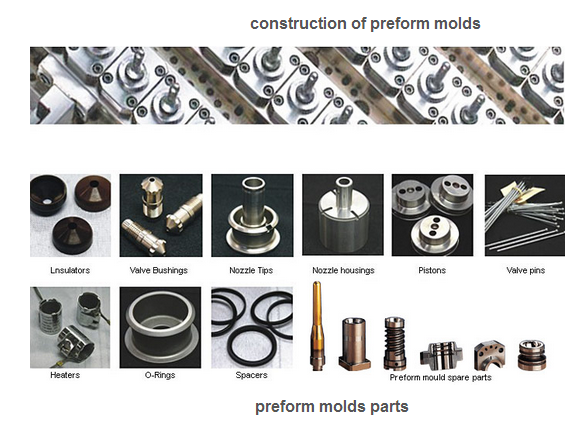

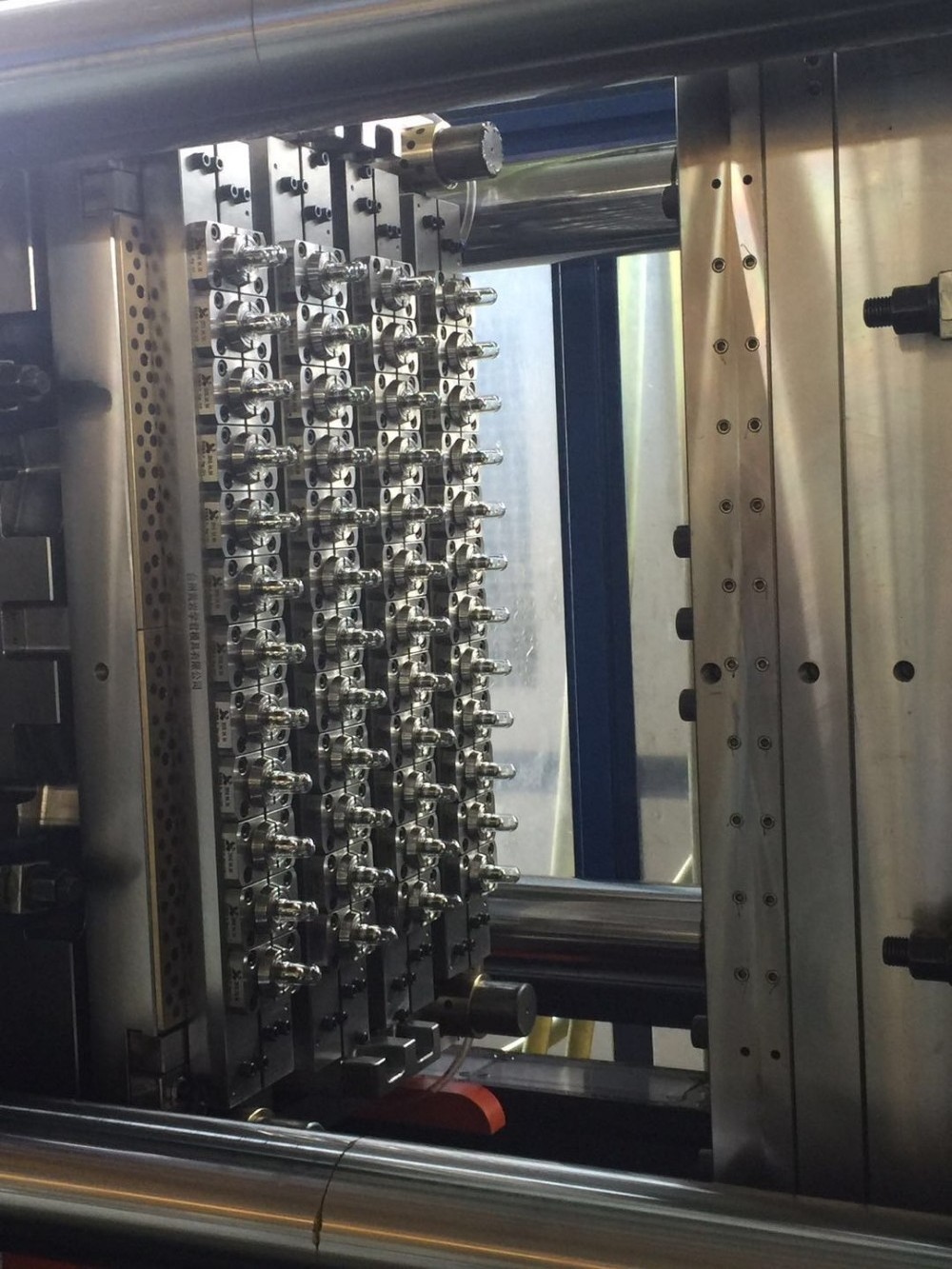

Hot runner system

XueJun series preform injection mold adopts specially designed hot runner system to achieve ideal and prompt heating effect for preform production. Lager flowing channels of such hot runner system ensures the mold to produce preform with lower injection pressure, which reduces molds each parts wear & tear and maintenance cost, and also saves electric energy.

Heating system

XueJun series preform mold with double heating system ensures perfect heating effect. It has separate temperature control mode: the heater bars are used to heat the molds manifold plate; the small heaters are used to supply the continuous heating temperature for cavity nozzle.

Cooling system

A specially designed cooling system with perfect cooling effect for each inner parts including core, cavity and valve gate system of XueJun preform injection mold.

Steel material and machining tools

Mold cavity and Core are made of imported mold steel with fine polishing, high hardness and anti-corrosion to guarantee mold's high precession and good quality.

Digital Control Lathe, EDM, jig-boring machine and high-precision grinding machine have been used on mold machining. High machining precision and fast machining speed ensure lONGE high quality molds

Heat treatment

After mechanical treatment, enhance steels strength and prolong mold service life. For example, we coat chrome on the mold plate surface for rustproof purpose and go on nitrogen treatment on neck part to increase its hardness. Special coatings also are available at XueJun Machinery. With right operation, PET preform mold reaches 2.5 million shots.

After-purchase service

Each set of mold undergoes strict mold trials before shipping from factory and attaches full set of parameter that is recorded depending on their own and sole serial number. Together with the mold, full set of spare parts will be supplied for free to keep mold normal working. In the use of the mold, LONGE provides adequate spare part to any request and LONGE service department are very willing to provide technical support immediately for any possible request in any time.

Address: No. 10, Meihuajing Road, Huangyan District, Taizhou, Zhejiang, China (Mainland)

Business Type: Manufacturer

Location: Zhejiang, China (Mainland)

Main Products: Preform mould,Blow mould,Cap mould

Total Employees: 20- 49 People

Year Established: 2005

Taizhou huangyan Xuejun mould factory is a professional manufacturer of PET moulds.we have been devoting ourselves to the research and production of bottle mold,perform mold,cap mold for many years.With strenuous improvement and innovations.It has become a famous enterprise in same line.We regularly produce PET perform moulds,blowing moulds and cap moulds for a variety of products from mineral water beverages,to medical devices,cosmetics,automotive parts,household items.

TaiZhou HuangYan XueJun Mould Factory

Add:NO.10 Meihuajin Road, HuangYan, TaiZhou, ZheJiang, China

Tel/Fax: +86-576-84115538

1. Engineer and one interpreter can be sent to customer’s factory for first running.

2. one-year after-sale technique support.

Q: Are you trading company or manufacturer ?

A: We are factory.Specialized in preform mould.

Q: Q:Where is your factory located? How can I visit there?

A:Our factory is located in HuangYan Taizhou City,ZheJiang province China.You can fly to Ningbo airport directly.We are warmly welcome to visit us,we can also take you from airport to our factory!

|

Contact person

|

Viki Ye

|

hu@china-petmould.com

|

|

|