- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

XUANHAI

-

Model Number:

-

NCY600

-

Voltage:

-

220v

-

Dimension(L*W*H):

-

5000 * 2100 * 2000 mm

-

Weight:

-

4200 KG

-

Max Speed:

-

300pcs/min

-

Product Name:

-

Paper Bag Machine

-

Paper Weight:

-

40-80 gsm

-

Performance:

-

Easy to Operate

-

Speed:

-

100-300pcs/min

-

Total Power:

-

8kw

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Food bag

-

Material:

-

Paper

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

XUANHAI

-

Model Number:

-

NCY600

-

Voltage:

-

220v

-

Dimension(L*W*H):

-

5000 * 2100 * 2000 mm

-

Weight:

-

4200 KG

-

Max Speed:

-

300pcs/min

-

Product Name:

-

Paper Bag Machine

-

Paper Weight:

-

40-80 gsm

-

Performance:

-

Easy to Operate

-

Speed:

-

100-300pcs/min

-

Total Power:

-

8kw

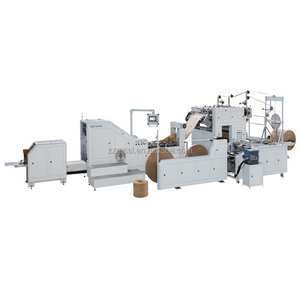

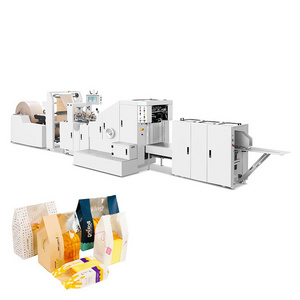

Structure features for paper bag making machine:

1、Suited for 40-80gsm paper.

2、Controls bag length through the human-machine interface.

3、PLC system for calculating parameters.

4、Equipped with an accurate photocell system.

5、This machine forming the paper bag in one process from roll paper, edge folding, tube forming, cutting, gluing, bottom folding, bottom gluing and finishing bag.

6、Easy operation, low power consumption, high efficiency.

7、It is an ideal machine for producing food bags like bread bags.

|

Paper weight

|

40-80gsm

|

|

Bag length

|

220-650mm

|

|

Bag width

|

80-300 mm

|

|

Speed

|

60-400pcs/min

|

|

Power

|

8kw

|

|

Total weight

|

3000kg

|

|

Max bag size

|

L*W 650*300mm

|

|

Min bag size

|

L*W 220*80mm

|

|

Paper weight

|

40-80 gsm

|

|

Machine dimension

|

5000*2100*2000mm

|

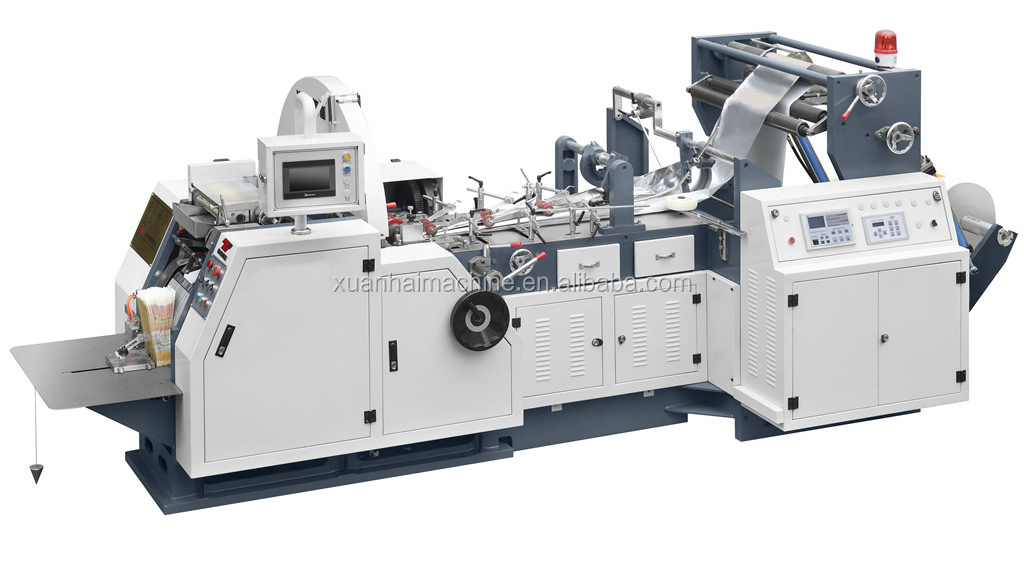

Structure features for flexo printing machine:

It is suitable for printing such packing materials as polyethylene, polypropylene bag, cellophane and paper in roll, etc. It is a

kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

It's quite commonly used for small order quantity printing service.

Performance and Features?

1. Easy operation, flexible starting, accurate color register.

2. The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the quantity or

when the material is cut off.

3. Pneumatic printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4. The printing ink is spread by the anilox cylinder with even ink color.

5. Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops.

6. 360°continuous and adjustable longitudinal register device.

7. The frequency control of motor speed adapts to different printing speeds.

8. There are Jogging/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

It's quite commonly used for small order quantity printing service.

Performance and Features?

1. Easy operation, flexible starting, accurate color register.

2. The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the quantity or

when the material is cut off.

3. Pneumatic printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4. The printing ink is spread by the anilox cylinder with even ink color.

5. Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops.

6. 360°continuous and adjustable longitudinal register device.

7. The frequency control of motor speed adapts to different printing speeds.

8. There are Jogging/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

Hot Searches