- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

10 year

-

Craftsmanship:

-

12,000 tons of forging

-

Custom inch:

-

R15 - 24 inch

-

Center hole distance:

-

Determined by car name

-

Raw material:

-

Aluminum-magnesium alloy

-

Wheels color:

-

Black, silver, other (we can customize 36 colors)

-

Surface treatment:

-

Galvanized / mirror polish / satin finish / painted

-

Wheels fastener:

-

bolt

-

Production cycle:

-

15 days

-

Stock quantity:

-

30000-50000

-

Certification:

-

TUV/ISO9001/VIA/IATF16949/OHSAS18001/DOT-T

Quick Details

-

Width:

-

7J-12J

-

Place of Origin:

-

China

-

Brand Name:

-

DUNHUI

-

Warranty:

-

10 year

-

Craftsmanship:

-

12,000 tons of forging

-

Custom inch:

-

R15 - 24 inch

-

Center hole distance:

-

Determined by car name

-

Raw material:

-

Aluminum-magnesium alloy

-

Wheels color:

-

Black, silver, other (we can customize 36 colors)

-

Surface treatment:

-

Galvanized / mirror polish / satin finish / painted

-

Wheels fastener:

-

bolt

-

Production cycle:

-

15 days

-

Stock quantity:

-

30000-50000

-

Certification:

-

TUV/ISO9001/VIA/IATF16949/OHSAS18001/DOT-T

Product Description

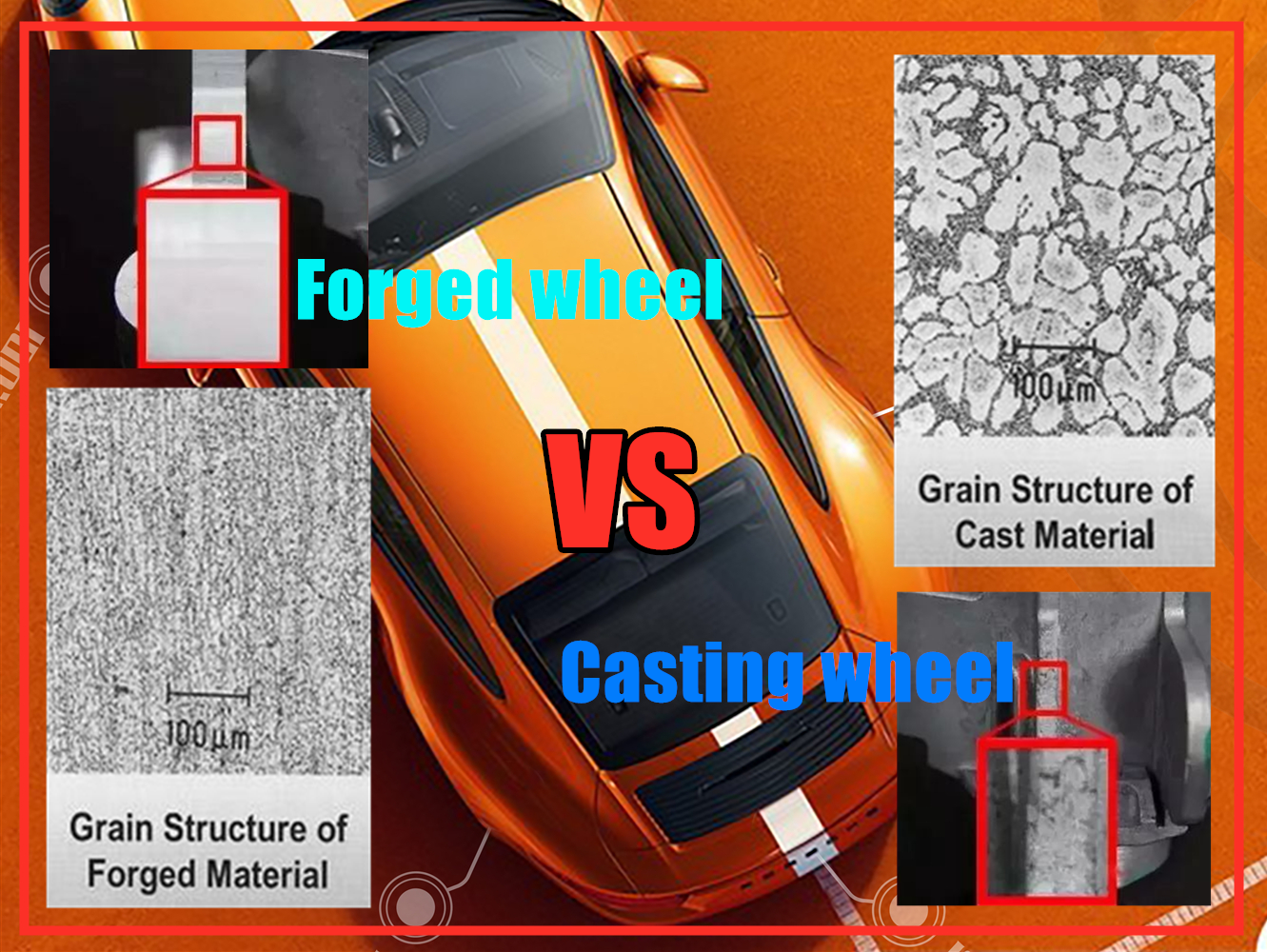

Forged wheel

Forged wheels have the most advanced Aluminum rim manufacturing technology .Compared with the casting processes,it has many outstanding advantages such as high strength,high safety,good roundness,light weight,good heat dissipation,more fuel-efficient.The original wheel hubs have single style and lacks individuality.It is easy to be deformed which exist safty risks.

The section of forged wheel

Forged technology is using forging machinery to make pressure to metal raw materials. Via moudling and trasforming,these stuff can get machanical capacitiy,size and shape.This process can elimiate loose of cast state and solder holes which make the aluminum materials have high density.

Detailed Images

Manufacturing Technique

The reasons of chosing forged wheels:

1.Individuality--It can satisfy the requirements of what you like.

2.Light weight--The car will have fast daynamic response and quick accelerating ability when using forged wheels.

3.High strength--High pressure makes the metal raw materials have tight molecular strcture which enhance the safty of car.

4.More fuel-efficient--When each wheel reduces 5-8kg weight,equivalently the car will reduce 100-120kg. Then the fuel using will decline.

5.Protecting the engine of car--The light weight of the wheels will reduce loading of engine and prolong life ofengine.

6.Good roundness--It can improve the riding performance and comfort.

|

Manufacturing period:

|

|

|

|

One pice wheel:

|

20 working days after the design drawing is confirmed(Postponement due to the holiday)

|

|

|

Two pices wheel:

|

30 working days after the design drawing is confirmed (Postponement due to the holiday)

|

|

|

Three pices wheel:

|

50 working days after the design drawing is confirmed(Postponement due to the holiday)

|

|

Packing & Delivery

The information of custom-made wheel hub:

1.the brand of car and the size of the original wheel hub.

2.Modifing the parameters(eg.CB,PCD,R,J,ET)

3.The style of wheel hub.(Please send a clear front view to us.)

2.Modifing the parameters(eg.CB,PCD,R,J,ET)

3.The style of wheel hub.(Please send a clear front view to us.)

Exhibition

Why Choose Us

It is life free to retain the original design paper which is easy for you to make it up anytime.

When the design paper is confrimed,we are not support of returning without any reason.

When the design paper is confrimed,we are not support of returning without any reason.

Hot Searches