Force-water concurrent; Thin-layer dewatering; Moderate press; Extension of the dewatering path

It has solved several technical problems of other similar sludge dewatering equipment including belt presses, centrifuge machines,

plate-and-frame filter press have, which are frequent clogging, low concentration sludge / oil sludge treatment failure, high

energy consumption and complicated operation etc

- Product Details

- {{item.text}}

Quick Details

-

name:

-

Sludge dewatering Screw Press for wastewater sludge dehydrator

-

Advantage:

-

long service life

-

Material:

-

Stainless Steel 304

-

Usage:

-

sludge dewatering

-

voltage:

-

220 380 415v

-

Control:

-

Automatic Control

-

Certificate:

-

CE/ISO 9001/ IS0 14001

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Shandong, China

-

Weight:

-

300 kg

-

name:

-

Sludge dewatering Screw Press for wastewater sludge dehydrator

-

Advantage:

-

long service life

-

Material:

-

Stainless Steel 304

-

Usage:

-

sludge dewatering

-

voltage:

-

220 380 415v

-

Control:

-

Automatic Control

-

Certificate:

-

CE/ISO 9001/ IS0 14001

Product Description

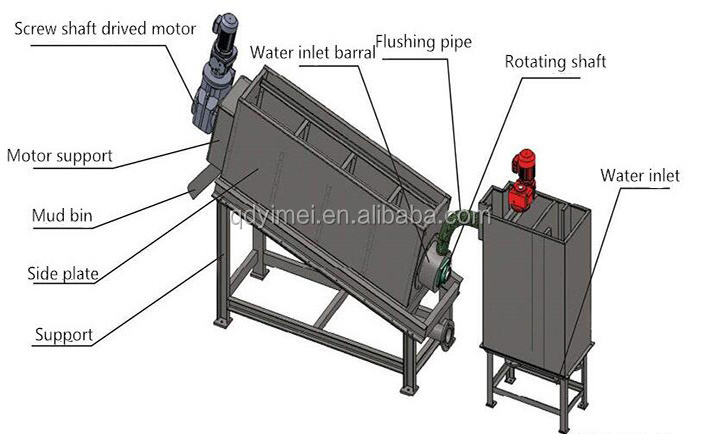

Main Parts:

Sludge concentration & dewatering Body; Flocculation & Conditioning Tank; Integrate Automatic Control Cabinet; Filtrate Collection

Tank

Sludge concentration & dewatering Body; Flocculation & Conditioning Tank; Integrate Automatic Control Cabinet; Filtrate Collection

Tank

Product Description

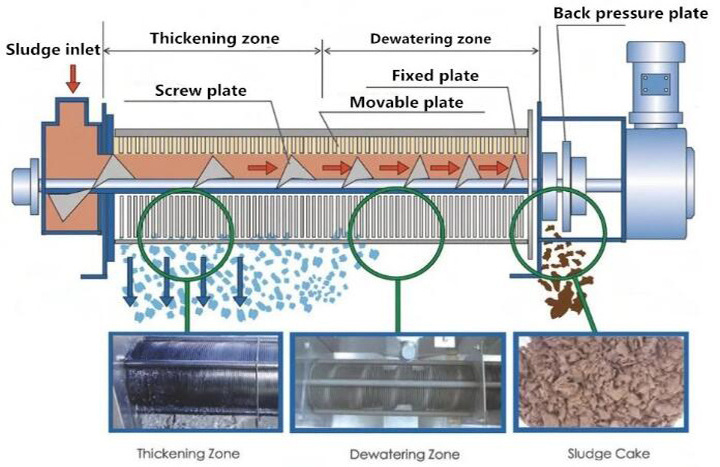

Working Principle

Thickening:

When the shaft is driven by the screw, moving rings around the shaft move up and down relatively. Most water is

pressed out from the thickening zone and fall down to the filtrate tank for gravity.

pressed out from the thickening zone and fall down to the filtrate tank for gravity.

Dewatering:

The thickened sludge moves forward continuously from the thickening zone towards the dewatering zone. With the pitch

of the screw shaft thread getting narrower and narrower, the pressure in the filter chamber increases higher and higher. In

addition to the pressure generated by the back-pressure plate, the sludge is greatly pressed and dryer sludge cakes produce.

of the screw shaft thread getting narrower and narrower, the pressure in the filter chamber increases higher and higher. In

addition to the pressure generated by the back-pressure plate, the sludge is greatly pressed and dryer sludge cakes produce.

Self-cleaning:

The moving rings rotates continuously up and down under the pushing of the running screw shaft while the gaps

between the fixed rings and moving rings are cleaned to prevent from clogging that happens frequently for traditional dewatering

equipment.

Product Feature:

Special pre-concentrating device, wide feed solids concentration: 2000mg/L-50000mg/L

The dewatering part of MSP consists of a thickening zone and a dewatering zone. In addition, a special pre-concentrating device is

mounted inner the flocculation tank. Therefore, the wastewater with rather low solids content is not a problem to MSP. The

applicable feed solids concentration can be as very wide as 2000mg/L-50000mg/L.

between the fixed rings and moving rings are cleaned to prevent from clogging that happens frequently for traditional dewatering

equipment.

Product Feature:

Special pre-concentrating device, wide feed solids concentration: 2000mg/L-50000mg/L

The dewatering part of MSP consists of a thickening zone and a dewatering zone. In addition, a special pre-concentrating device is

mounted inner the flocculation tank. Therefore, the wastewater with rather low solids content is not a problem to MSP. The

applicable feed solids concentration can be as very wide as 2000mg/L-50000mg/L.

Model list

Product project site

Hot Searches