- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

K-BD-DN200

-

Brand Name:

-

KBY

Quick Details

-

Port Size:

-

DN200

-

Warranty:

-

1year

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

K-BD-DN200

-

Brand Name:

-

KBY

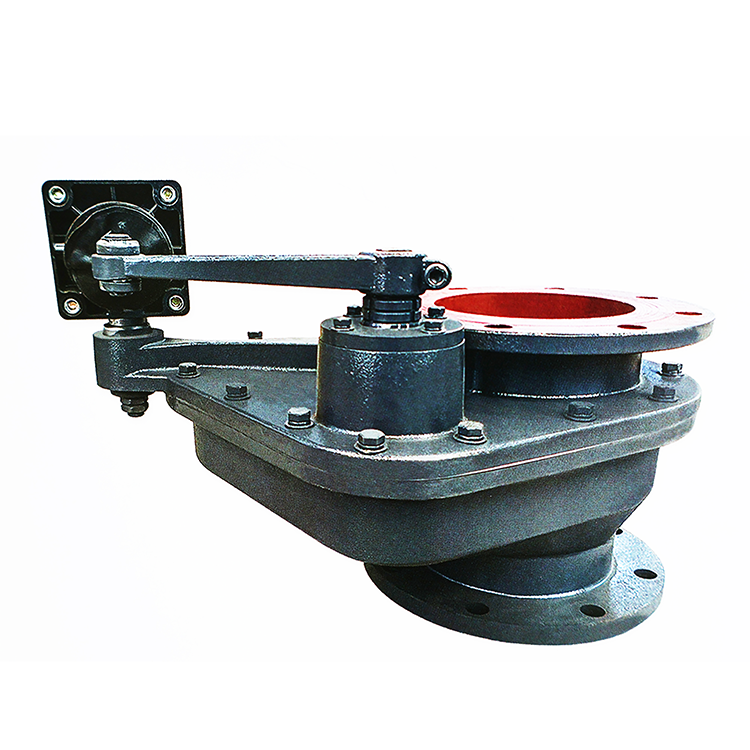

Low noise compact structure stable operation good seal pneumatic valve parts shot peening machines valves

Working principle

The valve uses the built-in bidirectional spring to reverse press the two valve plates on the sealing surface track at both ends of the valve,and manually or vertically pull the two valveplates to move synchronously to meet the requirements of opening and closing.First, the two valve plates on the sealing surface track at both ends of the valve, and manually or working principle: The valve uses the built-in bidirectional spring to reverse pressure the vertically pull the two valve plates to move synchronously to meet the requirements of opening and closing.

The discharger runs smoothly, has low noise and few faults, and the tooth fitting parts are made of ductile iron and bearing steel

UNIFORM FEED

Feed uniform and stable, shape,

beautiful, small size, light weight

Compact structure, good sealing stable operation, small impact inertia force

|

Product name

|

Wear-resistant material

|

|

Pneumatic ceramic swing valve

|

Ceramic or alloy

|

|

Pneumatic double plunger valve

|

Ceramic or alloy

|

|

Pneumatic dome valve

|

Rubber seal ring

|

|

Pneumatic three-way shunt (reversing) valve

|

Stainless steel

|

|

Bin pump

|

customizable

|

|

AV pump

|

customizable

|

Shandong kimbaiyi Industrial Te-

chnology Co., Ltd.

is a professional

service provider that integrates

scientific research, service, and sales. it is also a service providerthat provides comprehensive shot blasting and sandblasting process

solutions. Create a one-stop service

for customers and provide them with

a good user experience.

* since its establishment, the company has actively focused on the development and research of its main products, always adhering to the development concept of "techno- logy leading.customer first", in order to improve the international competitiveness of the enterprise and shape a first-class Jinbaiyi brand.

* The company has a professional technical research and development team that can provide professional technical services for different types of workpieces according to customer requirements. It can also display the surface treatment effect of workpieces through 3D simulation software to achieve customer satisfaction.

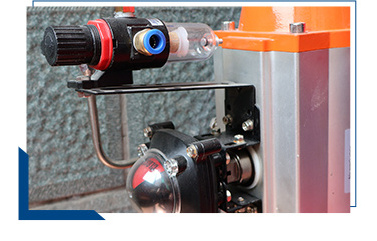

* The electrical system equipped with the equipment has advantages such as high eff- ciency, energy conservation,high degree of automation, and friendly human-machine interface.

* Our company has developed an intenationally leading remote monitoring and fault diagnosis system,which enables real time monitoring and fault detection of equipment, enabling earty detection and troubleshooting, ensuring efficient operation of equipment.

Q

How to install the machine?

A: Complete equipment of shot blasting machine, Standard equipment can choose remote guided installation. We will arrange 1-2 engineers to guide the installation and assembly of non-standard equipment at your factory.

Q

Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We can provide products such as steel shot, steel sand, steel wire cutting shot. stainless steel shot, and other metal abrasives related to surface cleaning and anti-corrosion.

Q

How long is your delivery time?

A: Generally Standard shot blasting machine 7-20 workdays. Non-Standard Shot blasting machine is 20-60 workdays. Shot peening machine is 30-60 workdays. It is according to quantity and machine model.

Q

What is the shot blasting machine?

A: Shot blasting is a method used to clean,strengthen (peen)or polish metal. Shot blasting is used in almost every industry that uses metal, including aerospace,automotive, constructi on, foundry, ship building rail, and many others.

Q

What are your pre-sales and after-sales services?

A: Pre sales services include: consulting products,samples, technical solutions and quota-tions, After sales service includes: 24-hour responseengineersonline guidance, enginee-rs' installation in the customer's factory, and training on how to instal and use the product.

Hot Searches