- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

224-221-9

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JINGCHEN

-

Model Number:

-

5858AB

-

Type:

-

General Purpose

-

Color:

-

Yellow/black,/milky white

-

Keywords:

-

two part epoxy potting compound

-

Hardness:

-

70~85

Quick Details

-

CAS No.:

-

4253-34-3

-

Other Names:

-

polyurethane resin

-

MF:

-

NONE

-

EINECS No.:

-

224-221-9

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JINGCHEN

-

Model Number:

-

5858AB

-

Type:

-

General Purpose

-

Color:

-

Yellow/black,/milky white

-

Keywords:

-

two part epoxy potting compound

-

Hardness:

-

70~85

PRODUCT DESCRIPTION

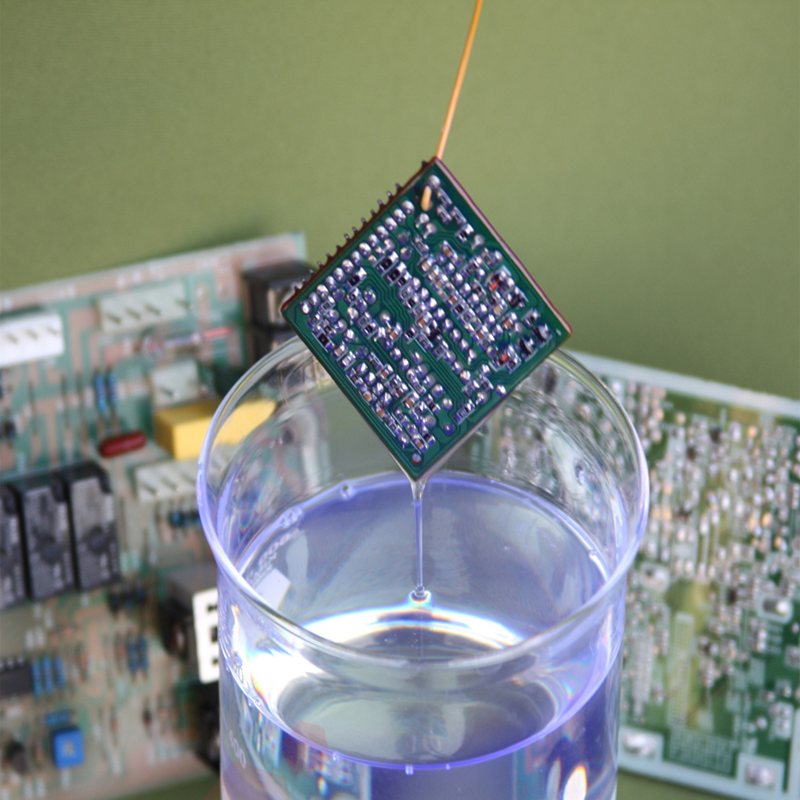

The 5885AB Silicone Coating is a low viscosity neutral silicone with a solids content of 100%, easy to spray, dip, brush or

cast. Protective coating for hard and soft printed circuit boards and protective coating of impregnated porous substrates.

FEATURES

l double component, low viscosity solvent-free, environmentally friendly

l High transparency, room temperature curing, good adhesion

l After curing at -60 - 200 ℃ stable and flexible

l And most of the substrate without primer coating has a good adhesion

l Excellent waterproof, anti-corrosion, moisture, electrical insulation properties

The 5885AB Silicone Coating is a low viscosity neutral silicone with a solids content of 100%, easy to spray, dip, brush or

cast. Protective coating for hard and soft printed circuit boards and protective coating of impregnated porous substrates.

FEATURES

l double component, low viscosity solvent-free, environmentally friendly

l High transparency, room temperature curing, good adhesion

l After curing at -60 - 200 ℃ stable and flexible

l And most of the substrate without primer coating has a good adhesion

l Excellent waterproof, anti-corrosion, moisture, electrical insulation properties

TYPICAL PROPERTIES:

|

Type

Item

|

5885A

|

5885B

|

|

|

color

|

Brown transparent liquid

|

Beige/white/black liquid

|

|

|

Viscosity(cps)

|

200±50

|

1000±200

|

|

|

Mixed viscosity(cps)

|

500±200

|

|

|

|

density(g/ cm³)

|

1.15±0.05

|

1.2±0.05

|

|

|

Use ratio (weight ratio)

|

A:B=30:100

|

|

|

|

Working temperature (℃)

|

-40~120℃

|

|

|

|

Operation time (min)

|

20

|

|

|

|

Curing condition

|

Curing at room temperature

|

|

|

|

Gel time (min)

|

25

|

|

|

|

Hardness after curing (Shore A)

|

85

|

|

|

|

Curing time

|

Cure at room temperature at 25℃ for 4~6 hours

|

|

|

|

|

60℃ heating for 60 minutes 80℃ heating for 30 minutes

|

|

|

|

Thermal Conductivity

|

0.55

|

|

|

|

Breakdown voltage (kv/mm)

|

23

|

|

|

|

Surface resistivity (Ω)

|

1.0×1013

|

|

|

|

Volume resistivity (Ω.cm)

|

>1013

|

|

|

|

Glass transition temperature (℃)

|

15℃TMA

|

|

|

|

Water absorption

|

After 30 days of soaking, 0.5%

|

|

|

|

Dielectric constant

|

at 50Hz ,23℃ 5.6 IEC 60250

at 1KHz,23℃ 4.6 VDE 0303,TI.4

at 1MHZ,23℃ 3.7

|

|

|

|

Coefficient of expansion

|

54-6

0*10 -6 |

|

|

Product Description

Packing & Delivery

10g,15g,30g,50g,80g,100g,200g,250g,500g,1kg

Hot Searches