- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

30 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Vina

-

Voltage:

-

380V,50Hz or Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

120

-

Weight:

-

36000 KG

-

Product Type:

-

Pvc Profile Extrusion Machine

-

Raw material:

-

PVC Powder+additatives

-

Automatic Grade:

-

High Automation

-

Color:

-

Customers' Require

-

Motor:

-

Siemens Beide

-

Inverter:

-

ABB Brand

-

Screw type:

-

Twin Conical Screw

-

Temperature control:

-

Omron Brand

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

Other

-

Screw diameter (mm):

-

Other

-

Screw Speed (rpm):

-

30 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Vina

-

Voltage:

-

380V,50Hz or Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

120

-

Weight:

-

36000 KG

-

Product Type:

-

Pvc Profile Extrusion Machine

-

Raw material:

-

PVC Powder+additatives

-

Automatic Grade:

-

High Automation

-

Color:

-

Customers' Require

-

Motor:

-

Siemens Beide

-

Inverter:

-

ABB Brand

-

Screw type:

-

Twin Conical Screw

-

Temperature control:

-

Omron Brand

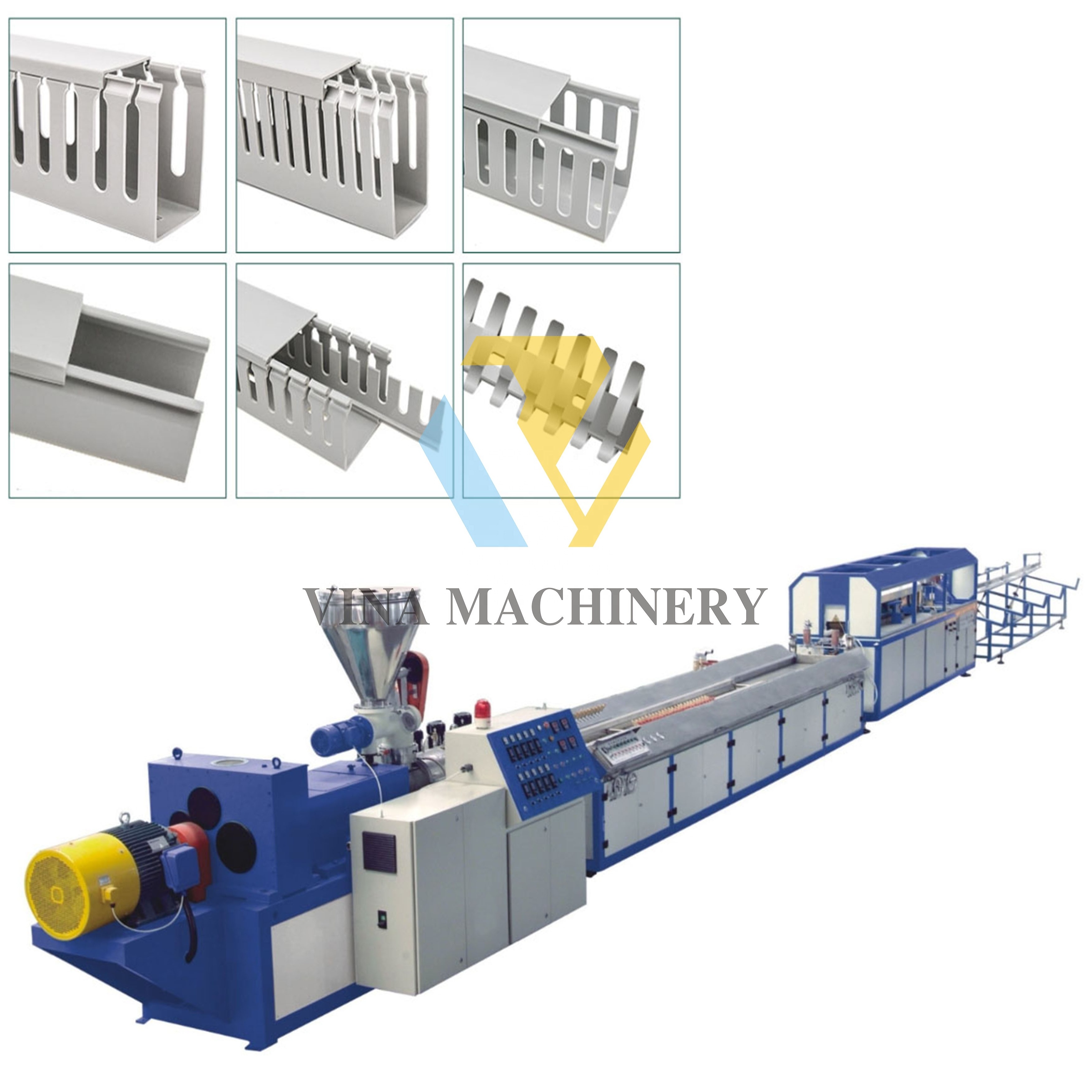

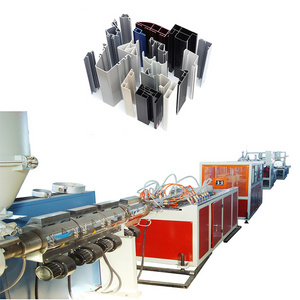

Products Description

>>

Use

:For production of soft PVC profile, rigid PVC profile, soft-hard co-extrusion profile,foam profile extrusion, multi layer

co-extrusion etc.

co-extrusion etc.

>>

Process Flow

:

Screw Loader →cone / parallel Twin Screw Extruder/Single screw extruder → Co-extrusion machine → Mould →Calibration Table → Haul-off & Cutter →Tripping Table → Final Product Inspecting & Packing

Details Images

High speed mixer

Used for different density of powder/particles/additives/color powder/color master/plastic and other materials mixing and mixing evenly, in order to adapt to the mixing requirements of some raw materials, the equipment is equipped with insulation device, can be used for cooling, heating and insulation of raw materials.

Screw conveyor

Used for raw material feeding to extruder, mixing machine

Loading control: time relay automatic control

Conical twin screw extruder

The solid material is plasticized and fused into a uniform temperature melt and continuously extruded

• World famous brand electrical component such as Siemens,Schneider, ABB etc;

• High torque gearbox with adopts NSK/SKF bearing;

• Siemens/WEG original motor achieved global after service;

• Bimetallic screw and barrel;

• Intelligent PLC controlling system with human-friendly interface.

Extrusion mould

Change the shape of the molding material through the mold

• 3Cr13/3Cr17 material;

•Complete set include extrusion die head, calibrator and cooling tank;

• Apply to soft PVC, rigid PVC,

soft-hard co-extrusion profile, foamed profile, multi-layers co-extrusion etc.

soft-hard co-extrusion profile, foamed profile, multi-layers co-extrusion etc.

Vacuum Calibration Table

After exit from the die head, enter the cooling mold immediately. The mold is vacuized, so that the outer wall of the profile and the surface of the molding mold are tight, and the water is cooled by the molding sleeve. The adsorption force of the vacuum is required and uniform, so as to ensure the appearance and dimensional precision and apparent quality of the profile.

• Include full set of vacuum and water pump;

• Length from 4m-11.5m;

• Independent operation panel for easy operation.

Caterpillar Haul off machine

After the extruder extrudes the raw material through the mold. The tractor clamps the profile from its outlet and then pulls it to a certain length, which reaches the predetermined extruded length

• Upper and lower caterpillar is driven separately and speed control by frequency inverter;

• Fast change type pads for easy operation;

• Install plate is adopts aluminum material;

Cutting Machine

The continuous extrusion products are cut into a certain length by the cutting machine according to the requirements

• Compacting driving by pneumatic;

• Tracking cutter or lifting saw cutter with adopts double station dust collection system;

• Synchronous driving by air cylinder or servo motor control.

Product collection and placement machine

Collect and arrange the cut product

• Stainless steel304 as touching material;

• Discharge driving by air cylinder.

Final product reference

Product Paramenters

|

Max profile width (mm)

|

Extruder model

|

Designed capacity(kg/h)

|

Extruder motor power(kw)

|

|

180

|

51/105 or 55/110

|

80-120/120-150

|

18.5/22

|

|

240

|

65/132

|

175-250

|

37

|

|

300

|

65/132

|

175-250

|

37

|

|

400

|

65/132 or 80/156

|

175-250/250-350

|

37/55

|

|

600

|

65/132 or 80/156

|

175-250/250-350

|

37/55

|

|

800

|

80/156

|

280-350

|

55

|

|

Technical Parameter of Main extruder

|

|

|

|

|

|

|

|

|||||||

|

Model

|

Power

(kw)

|

Screw Diameter (mm)

|

Screw Qty

|

Screw rotation speed(rpm)

|

Designed Output (kg/h)

|

Center Height (mm)

|

Dimension(L*W*H)

(mm)

|

|||||||

|

45/90

|

15

|

Φ45/90

|

2

|

34.7

|

70

|

1050

|

3360*1290*2127

|

|||||||

|

51/105

|

18.5

|

Φ51/105

|

2

|

34.7

|

100

|

1050

|

3360*1290*2127

|

|||||||

|

55/110

|

22

|

Φ55/110

|

2

|

34.7

|

150

|

1050

|

3620*1050*2157

|

|||||||

|

65/132

|

37

|

Φ65/132

|

2

|

34.7

|

300

|

1050

|

3715*1520*2450

|

|||||||

|

80/156

|

55

|

Φ80/156

|

2

|

34.7

|

400

|

1050

|

4750*1550*2460

|

|||||||

|

92/188

|

110

|

Φ92/188

|

2

|

34.7

|

750

|

1250

|

6725*1550*2814

|

|||||||

Product packaging

Packaging & Shipping:

1.For the loose cargo we will packing by wooden box

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client's warehouse to loading

6.We have free spare parts with the machine.

2.For the full container loading we are packing the machine by film and some on pallet accordingly

3.We can shipping the goods by air or by sea

4.We will send pictures of cargo loading to our client to check and keep recording

5.We can send cargo to client's warehouse to loading

6.We have free spare parts with the machine.

FAQ

Contact us

If you consult, we do not have the first time to reply, please leave your contact information or add our contact information, we see the message, will be the first time to reply

Q:Are you machinery factory or trading company?

A:We have our own factory,which means we can strictly guarantee product quality and lead time.

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Do you provide material testing service?

A:We have our own factory,which means we can strictly guarantee product quality and lead time.

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Do you provide material testing service?

A: Yes, we offer testing service on our machine. An additional testing fee will

becharged depends on the testing costs(electricity, labor), however, if you eventually made a purchase with us ,the testing fee will counts to deduction of machine purchase cost.

Q: How can I make sure the machine running good in my plants?

A: First we will have a home commissioning in our factory for your inspection. If you need assistance in installing and staff training , we can also send engineers to service overseas and solve all problems. (notice: return flight and $80 per day salary will be on customer)

Q: How to get a quote efficiently?

A: Please kindly click on ' Sent An Inquiry ' Button at the bottom of page,or click "Chat now"on the right side of the page. Leave a message to describe details of your final products ( better with a picture and size drawing), Capacity requirements, We will reply to your inquiry within 12 hours

Q: How can we visit your company and machines?

A : Our factory is in Jinfeng Town, Zhangjiagang City, Jiangsu Province, China. About 2.5hours from Shanghai Pudong International Ariport.

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc

becharged depends on the testing costs(electricity, labor), however, if you eventually made a purchase with us ,the testing fee will counts to deduction of machine purchase cost.

Q: How can I make sure the machine running good in my plants?

A: First we will have a home commissioning in our factory for your inspection. If you need assistance in installing and staff training , we can also send engineers to service overseas and solve all problems. (notice: return flight and $80 per day salary will be on customer)

Q: How to get a quote efficiently?

A: Please kindly click on ' Sent An Inquiry ' Button at the bottom of page,or click "Chat now"on the right side of the page. Leave a message to describe details of your final products ( better with a picture and size drawing), Capacity requirements, We will reply to your inquiry within 12 hours

Q: How can we visit your company and machines?

A : Our factory is in Jinfeng Town, Zhangjiagang City, Jiangsu Province, China. About 2.5hours from Shanghai Pudong International Ariport.

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc

Zhangjiagang Vina Machinery Co., Ltd. is the professional manufacturer for kinds of plastic machines, such as 3D printer filament extruder, plastic pipe extrusion line, plastic profile extrusion line, waste plastic recycling machine, plastic crusher & Shredder and plastic process auxiliary machines, etc.

The target of Zhangjiagang Vina Machinery Co., Ltd is to offer the best quality machines to the customers from all over the world. With the advanced technology, experienced engineers and skilled workers, we

have the capability to manufacture specific machines according to customer's requirement. Excellent quality and professional service is the promise made by Zhangjiagang Vina Machinery Co., Ltd to new and old friends.

We are looking forward to establishing the good cooperation relationship with you on the basis of mutual benefits.

have the capability to manufacture specific machines according to customer's requirement. Excellent quality and professional service is the promise made by Zhangjiagang Vina Machinery Co., Ltd to new and old friends.

We are looking forward to establishing the good cooperation relationship with you on the basis of mutual benefits.

Hot Searches