- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

As request

-

Power:

-

5.5KW/booth; 5.5KW/oven;

-

Dimension(L*W*H):

-

4000*800*2000mm for booth

-

Weight (KG):

-

2500

-

Brand:

-

HICOLO

-

Product name:

-

Automatic production powder coating painting spray line

-

Application:

-

Metal Surface Finishing

-

Used for:

-

Powder Coated Parts Curing

-

Booth Operating Dimensions:

-

Width800 * Height2000 * Depth4000mm

-

Fan Power:

-

5.5kw, 2 sets

Quick Details

-

Machine Type:

-

Automatic powder coating line, Spray Booths, Painting Equipment, Curing oven, Coating Equipment

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

COLO

-

Voltage:

-

As request

-

Power:

-

5.5KW/booth; 5.5KW/oven;

-

Dimension(L*W*H):

-

4000*800*2000mm for booth

-

Weight (KG):

-

2500

-

Brand:

-

HICOLO

-

Product name:

-

Automatic production powder coating painting spray line

-

Application:

-

Metal Surface Finishing

-

Used for:

-

Powder Coated Parts Curing

-

Booth Operating Dimensions:

-

Width800 * Height2000 * Depth4000mm

-

Fan Power:

-

5.5kw, 2 sets

Products Description

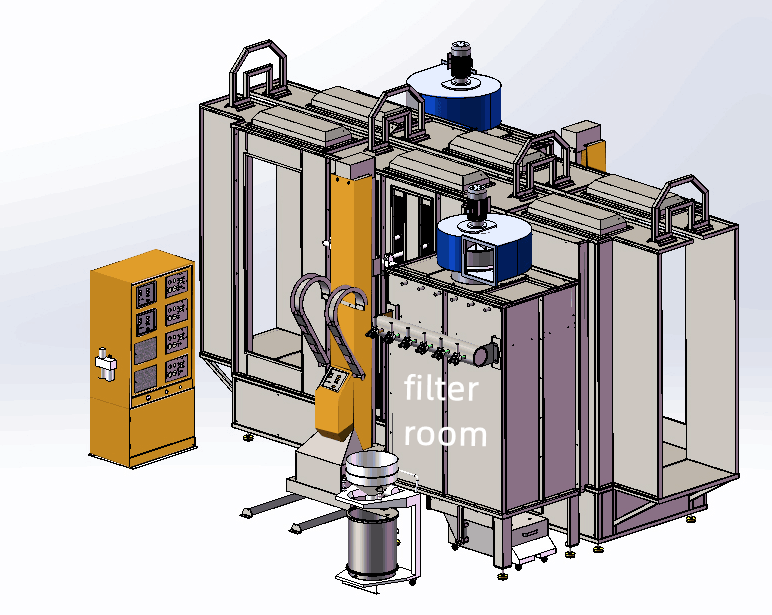

Automatic Production Powder Coating Plant Line For Aluminum Profiles

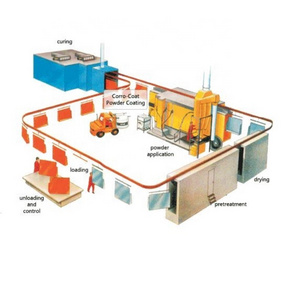

Automatic powder coating lines are widely used for continuous finishing of metal parts, such as alloy wheels, furniture (doors, beds, cabinets, outdoor chairs and tables), LPG cylinders, fire extinguishers, fences, pallet racks, shelves, etc.

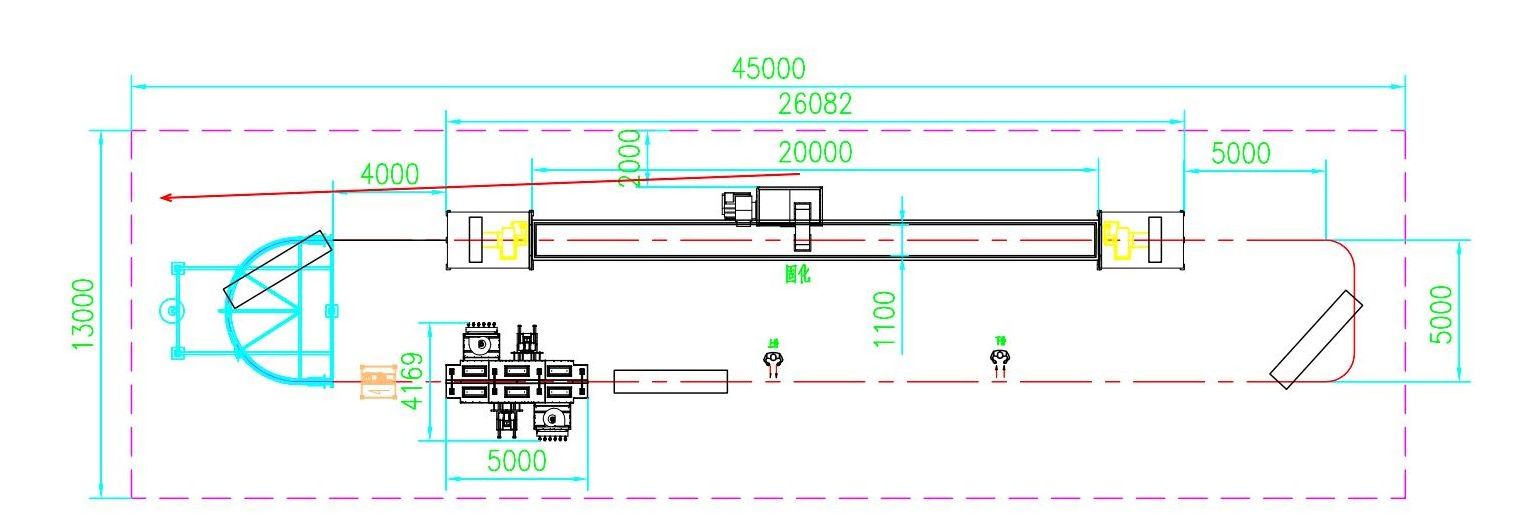

This is a case drawing for reference, the automatic line include the automatic powder coating booth, continuous oven and necessary coating machines, like reciprocators and automatic powder coating guns.

Details

COLO-0825 Automatic Tunnel Powder Coating Booth

It is an automatic type tunnel powder coating booth with filter powder coating room to realize a certain larger powder coating job.

|

Model

|

colo-s-0825

|

Work size

|

W800*H2000*L4000mm

|

|

|

|

Powder recovery type

|

filters, two filter rooms

|

filter qty

|

12filters, a filter room with 6pcs filter

|

|

|

|

filter cleaning

|

pneumatic

|

booth material

|

powder coated steel or stainless steel

|

|

|

It is a filter powder recovery type of booth, suitable for less color changes.

Booth equipped with two filters rooms and two powder collected bin to storage the used powder coating which gonna be reuse.

Cartridge filter

Powder collect bucket

Air storage tank Fan motor

COLO Customized Continuous Powder Coating Oven

Continuous conveying oven with non stop heating, oven and booth uses the same continuous moving conveyor system.

The oven two ends usually with the air curtain.

|

Model

|

Continuous oven

|

Working Size

|

20 meter long

|

|

Materal

|

100mm rock wool board ,new

|

Controller

|

Digial PLC Controller

|

|

Heating Source

|

Gas/LPG/diesel/electric

|

Burner

|

Italy Riello

|

|

Warn-up Time

|

15-30min (180 ℃)

|

Temperature Max.

|

250℃

|

Related Products

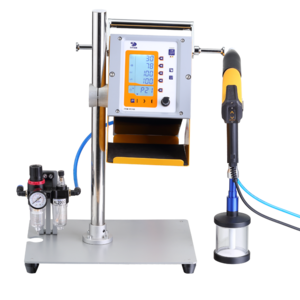

Automatic powder coating gun

usually use 6~8pcs automatic powder coating gus to paint the parts in the booth.

Reciprocator

used to carry the automatic powder coating guns and repeat the up and down moving automatically.

Powder sieving machine

used to connect to the powder coating booth and guns, transfer and recycle the powders for reuse.

Application

Automatic powder coating line is ideal for a wide range of applications, including metal panels, steel chairs, springs, aluminum profiles, and more.

Customer Case

Packing & Delivery

Packing: large systems usually packing by pearl cotton.

Lead time: Powder coating line usually about 50~60days

Our Company

PLEASE SEND US INQUIRY OR CALL FOR ORDERING, SHIPPING QUOTES, ESTIMATED LEAD TIMES. 0086-18069805616(WhatsApp)

Hot Searches