- Product Details

- {{item.text}}

Quick Details

-

Nominal clamping force:

-

0.50MN

-

Flat (hot plate) specifications:

-

400*400*thick60mm

-

Working layers:

-

1layer

-

Number of hot plates:

-

2 pieces

-

Hot plate spacing:

-

250mm

-

Hot plate parallelism:

-

≤0.15mm

-

Surface roughness of hot plate:

-

Ra≤2.5 μm

-

heating method:

-

Electric heating

-

Temperature control method:

-

Digital display

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

East YQ

-

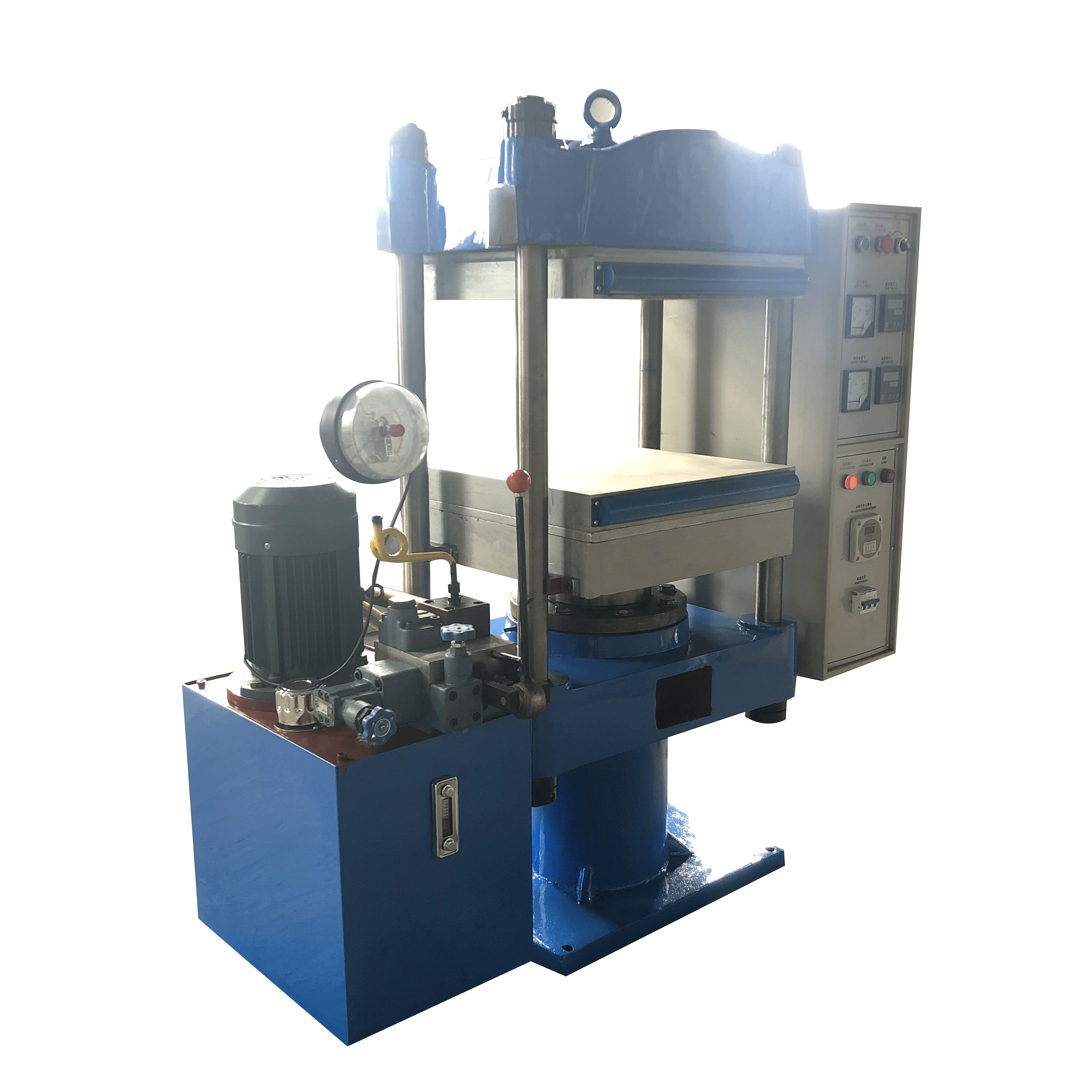

Product name:

-

Plate Vulcanizing Press

-

Nominal clamping force:

-

0.50MN

-

Flat (hot plate) specifications:

-

400*400*thick60mm

-

Working layers:

-

1layer

-

Number of hot plates:

-

2 pieces

-

Hot plate spacing:

-

250mm

-

Hot plate parallelism:

-

≤0.15mm

-

Surface roughness of hot plate:

-

Ra≤2.5 μm

-

heating method:

-

Electric heating

-

Temperature control method:

-

Digital display

Main technical parameters of equipment:

|

NO. |

Name |

Parameter |

Remarks |

|

1 |

Nominal clamping force |

0.50MN |

50t |

|

2 |

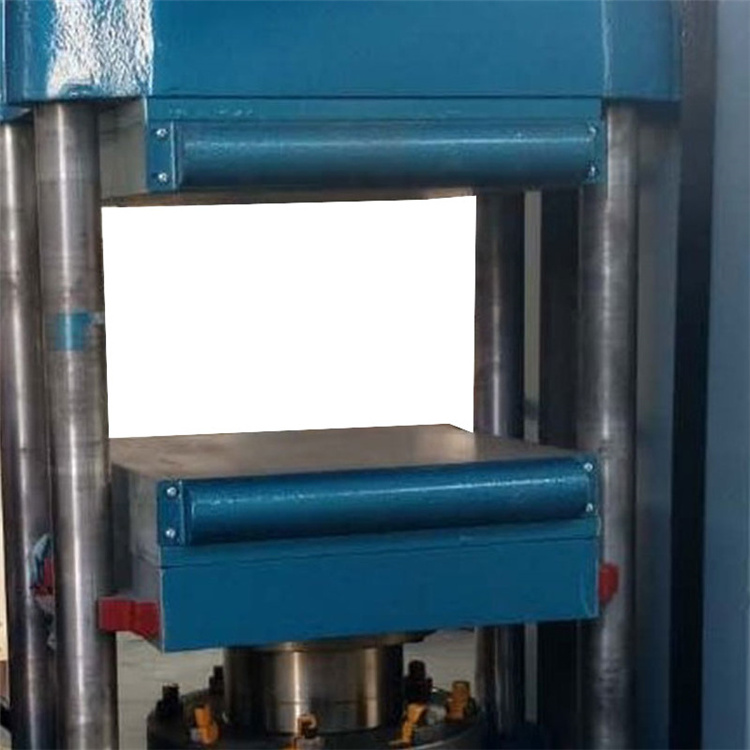

Flat (hot plate) specifications |

400*400*thick60mm |

Material: Q235 high quality carbon steel |

|

3 |

Working layers |

1layer |

|

|

4 |

Number of hot plates |

2 pieces |

|

|

5 |

Hot plate spacing |

250mm |

|

|

6 |

Hot plate parallelism |

≤0.15mm |

|

|

7 |

Surface roughness of hot plate |

Ra ≤2.5 μm |

|

|

8 |

heating method |

Electric heating |

|

|

9 |

Heating power of each heating plate |

500w*6roots=3.0kw |

|

|

10 |

Maximum heating temperature |

200°C |

|

|

11 |

Temperature control method |

Digital display |

|

|

12 |

Motor Power |

2.2KW |

|

|

12 |

Pressure per square centimeter |

32kg/cm ² |

|

|

13 |

Plunger stroke / diameter |

250mm / 200mm |

Material :QT500-7 |

|

14 |

Number of cylinders |

1set |

Material :QT500-7 |

|

15 |

Maximum system pressure |

16Mpa |

|

|

16 |

structure type |

Four-post |

|

|

17 |

Number of columns / diameter |

4 pillars / 50mm |

45 # steel |

|

18 |

control method : |

Semi-automatic control type |

|

|

19 |

Weight |

1200Kg |

|

Equipment use conditions and requirements:

The machine has the functions of automatic control of rising, automatic constant temperature, automatic pressure holding, vulcanization timing, alarm when the time comes, manual mold opening and falling;

The equipment pipes are connected by seamless steel pipes, pressure and oil resistant, and no noise is generated during work;

The entire hydraulic oil circuit system adopts advanced welding technology and sealing measures, there will be no oil leakage and oil leakage, and there will be no crawling or jitter during the pressurization process;

The equipment has automatic pressure compensation function during mold clamping to ensure that the pressure drop does not exceed 10% during the pressure holding process within one hour;

Immediately after the mold clamping action of the equipment is completed, high-pressure mold clamping is performed at a suitable speed. After the mold clamping, the air can be arbitrarily exhausted. The number of exhausts and the exhaust time are manually achieved. Immediately after the deflation action is completed, it is transferred to the state of holding pressure vulcanizer.

The hydraulic control system of this machine is controlled by manual control valve, and the template can stay at any position during the mold clamping process.

The equipment has process parameters that can be adjusted, such as: vulcanization time (99 minutes 59 seconds), vulcanization temperature (0-200 ° C) arbitrary adjustment settings.

Performance characteristics and configuration

1. The oil cylinder adopts advanced sealing structure, reasonable design and reliable performance.

2. The machine has the functions of automatic control of rising, manual exhaust, automatic constant temperature, automatic pressure holding, vulcanization timing, alarm when the time comes, manual mold opening and falling;

3. Description of the main components of the host

3.1. Column: The column is made of high-quality 45 # steel. After quenching and tempering, the strength and tensile force of the column are improved, and it is not easy to deform and break.

3.2. Plunger: The material of the oil cylinder is QT500-7, the cylinder diameter is 250mm, and the quantity is 1 piece.

3.3 The materials of the upper and lower bases and platforms are all QT500-7.

3.4. Hot plate: The hot plate is made of Q235A high-quality carbon-bonded steel, refined and ground after tempering, with good surface finish and strong abrasion resistance.

3.5. Seals: YX type polyurethane oil seals are used for oil cylinder seals, which are resistant to oil, aging and wear.

3.6. Electrical system: This electromechanical device adopts well-known brands of Chint and Delixi. The electric device has small volume, compact structure, fatigue resistance, and is adapted to continuous high-intensity work.

3.7. Insulating sheets are installed in the front and back covers of the hot plate of the machine.