- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JTSOR

-

Model Number:

-

1# 2# 3#

-

Product name:

-

Red Color Lithium Complex Grease for Wheel Hub

-

Keywords:

-

Lubricant Grease

-

NLGI:

-

3

-

Work Temperature:

-

-20~200℃

-

Drop point:

-

30~325 ℃

-

Color:

-

Yellow, Blue, Green, Red, etc

-

Appearance:

-

Smooth, Clear

-

Package:

-

Bag, Barrel, Drum, etc.

-

Capacity:

-

400g to 180kg

-

Certificate:

-

MSDS

Quick Details

-

Application:

-

Automotive Lubricant

-

Type:

-

Greases

-

Place of Origin:

-

Henan China

-

Brand Name:

-

JTSOR

-

Model Number:

-

1# 2# 3#

-

Product name:

-

Red Color Lithium Complex Grease for Wheel Hub

-

Keywords:

-

Lubricant Grease

-

NLGI:

-

3

-

Work Temperature:

-

-20~200℃

-

Drop point:

-

30~325 ℃

-

Color:

-

Yellow, Blue, Green, Red, etc

-

Appearance:

-

Smooth, Clear

-

Package:

-

Bag, Barrel, Drum, etc.

-

Capacity:

-

400g to 180kg

-

Certificate:

-

MSDS

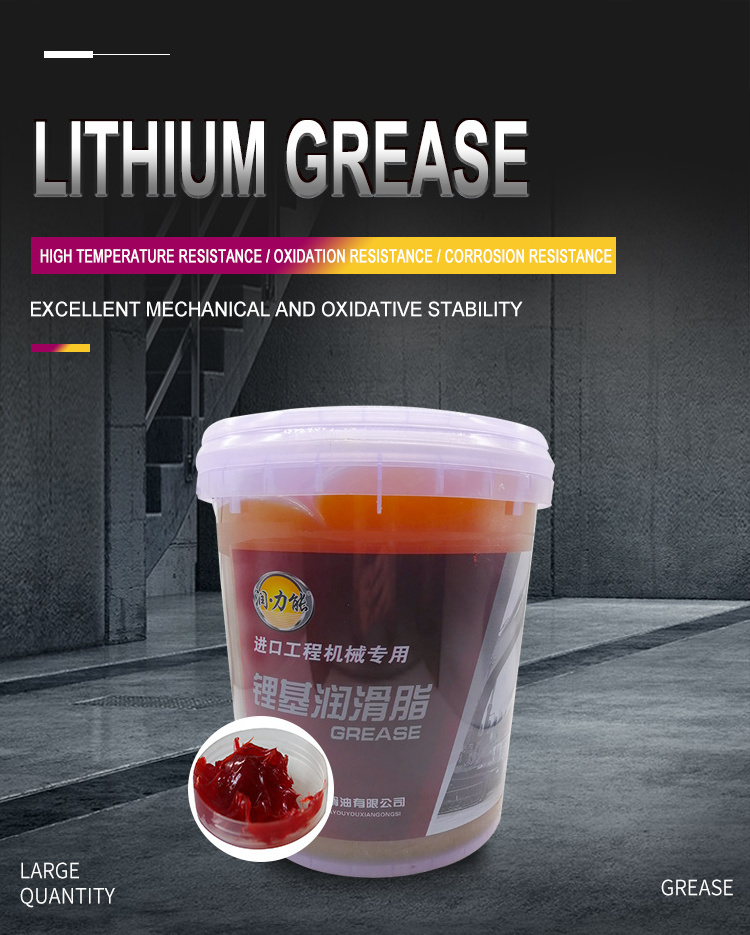

high quality marine Red Color Lithium Complex Grease for Wheel Hub import car mechanical motorcycle lubricant grease

Feathers

:

1.

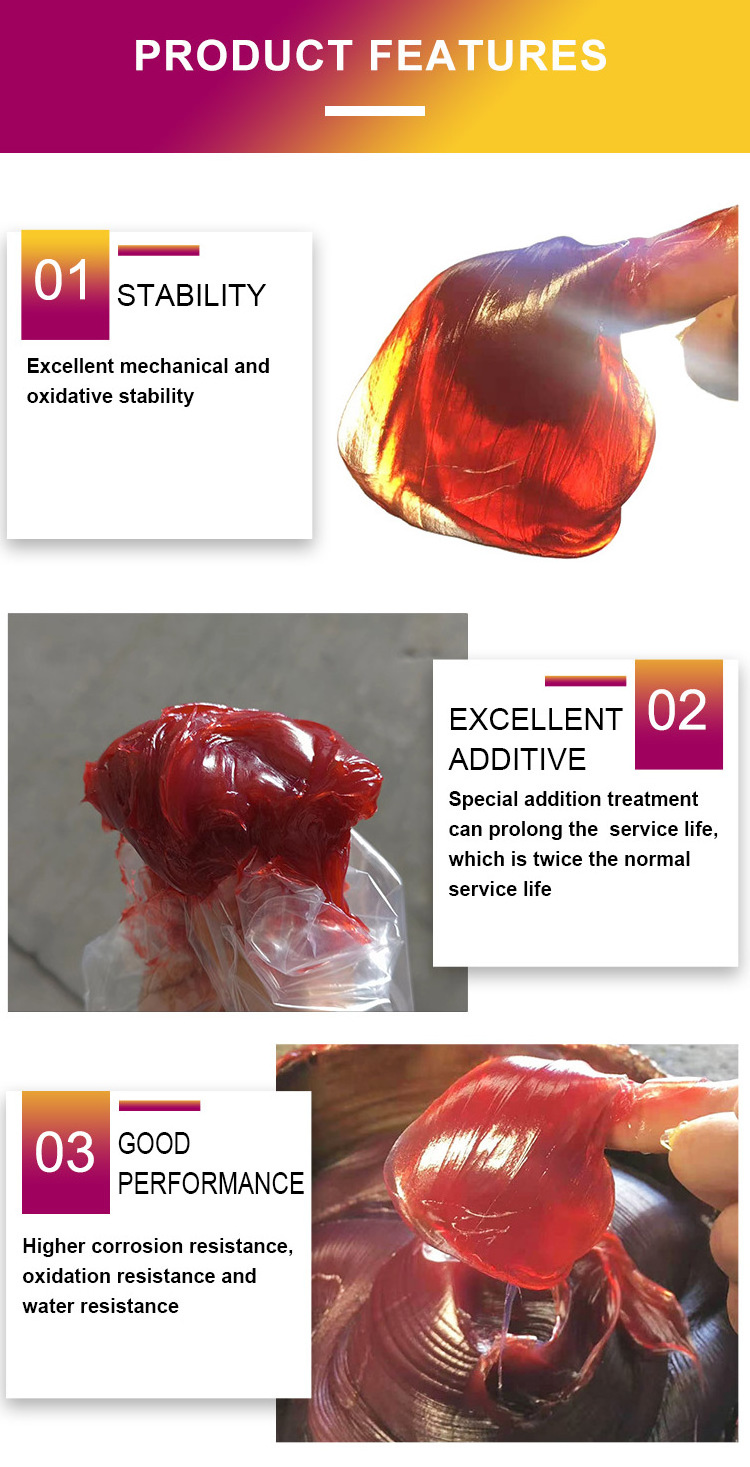

Excellent mechanical and oxidative stability

2. Special addition treatment can prolong the service life, which is twice the normal service life

3. Higher corrosion resistance, oxidation resistance and water resistance

2. Special addition treatment can prolong the service life, which is twice the normal service life

3. Higher corrosion resistance, oxidation resistance and water resistance

-Lithium thickening

-Completely refined base oil

-12 Lithium Hydroxystearate

-Optimized and enhanced additive processing

Has excellent oxidation stability, mechanical stability

Run under different conditions.

and washing characteristics to ensure trouble-free

-Completely refined base oil

-12 Lithium Hydroxystearate

-Optimized and enhanced additive processing

Has excellent oxidation stability, mechanical stability

Run under different conditions.

and washing characteristics to ensure trouble-free

Specification

|

Item

|

Type

|

|

|

|

|

2#

|

Test Methods

|

|

|

Appearance

|

smooth ointment yellow color

|

Visibility

|

|

|

Worked cone penetration, 0.1mm

|

284

|

Worked cone penetration, 0.1mm

|

|

|

Dropping Point,ºC ≥

|

185

|

GB/T 4929-1985

|

|

|

Worked cone penetration change ,100,000times @0.1mm

|

23

|

GB/T 269

|

|

|

Worked cone penetration change ,100,000times @0.1mm , 10% water

|

100

|

GB/T 269

|

|

|

Viscosity,(-15℃,10s^-1),(Pa·s)

|

462

|

SH/T 0048

|

|

|

Water leaching loss(38°,1h),%(m/m)

|

2

|

SH/T 0109

|

|

|

Oil Separation,24h@100ºC ,%

|

3.1

|

NB/SH/T 0324

|

|

|

Four ball Extreme Pressure Test Wear mark diameter(392N,75℃,1200rpm,60min),mm

|

0.7

|

SH/T 0204

|

|

|

Corrossion Preventive Properities,48h@52ºCRating

|

pass

|

GB/T 5018

|

|

|

Copper corrossion,T2 copper strip ,24h@100ºC rating

|

pass

|

GB/T 7326-1987

|

|

Product Features

Grease Usage Notice:

1. Position the grease in a ventilated, favorable temperature room.

2. Protected it from dust and impurities after open, close the drum lid after using.

3.Cleaning the parts of lubrication before using, don’t mix using with other grease.If there is a little oil impregnate, blend it before using.

1. Position the grease in a ventilated, favorable temperature room.

2. Protected it from dust and impurities after open, close the drum lid after using.

3.Cleaning the parts of lubrication before using, don’t mix using with other grease.If there is a little oil impregnate, blend it before using.

Production Process

Related Products

Hot Searches