- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

1218x650x1135mm

-

Weight:

-

155 KG

-

Print Dimension:

-

155x(108-401)mm

-

Printing material:

-

Stain tape,nylon tape,cotton tape,adhesive tape,and paper ect

-

Printing speed:

-

60m/min

-

Printing color:

-

2 Colors

-

Machine Type:

-

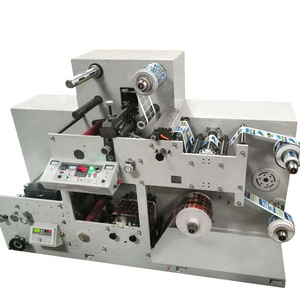

Flexo Letterpress Printing Machine

-

Printing width:

-

155mm

-

Printing length:

-

108-401mm

-

Anilox roller:

-

Ceramic Anilox Roller

-

Plate Thickness:

-

1.7mm

-

Heating Oven:

-

Infrared Light(IR)

-

Certification:

-

CE Certification

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JINGDA

-

Voltage:

-

220V

-

Dimensions(L*W*H):

-

1218x650x1135mm

-

Weight:

-

155 KG

-

Print Dimension:

-

155x(108-401)mm

-

Printing material:

-

Stain tape,nylon tape,cotton tape,adhesive tape,and paper ect

-

Printing speed:

-

60m/min

-

Printing color:

-

2 Colors

-

Machine Type:

-

Flexo Letterpress Printing Machine

-

Printing width:

-

155mm

-

Printing length:

-

108-401mm

-

Anilox roller:

-

Ceramic Anilox Roller

-

Plate Thickness:

-

1.7mm

-

Heating Oven:

-

Infrared Light(IR)

-

Certification:

-

CE Certification

|

No

|

Item

|

Data

|

|

1

|

Model

|

JR-1502

|

|

2

|

Print Width

|

10-155mm

|

|

3

|

Print Length

|

108-401mm

|

|

4

|

Print Color

|

Front side 2 colors

|

|

5

|

Max. Cut Speed

|

60m/min

|

|

6

|

Power

|

220V Single Phase 3.5KW

|

|

7

|

Net Weight

|

350kg

|

|

8

|

Packing Dimension

|

110x65x130cm

|

More Machine Videos: https://www.youtube.com/channel/UCYAiC7kqomHXiDiz0URcVbg/videos

Specifications

1) Flexo Printing Machine For Tapes

2) It is used for flexo label printing in ribbons;cotton tape ;woven label;nylon tape, paper

Feature:

* The printing mechanism of this series is that ink will be evenly spread-out on the ink-rollers at first,from the

ink-rollers,the ink transfers to the printing cylinder.

* The flexo photopolymer plate will collect the ink and press directly on the surface of the materials.

* The label will go through the drying process to complete the whole printing procedures.

* The printed label can reach the result of higher strong washing fastness by heating inside the H90 Automatic Temperature

Controlled Oven between 3-8 hours.

* Strong colorfastness to wash and polish,perfect colour registration,stability the different printing cylinders.

* Printing front 4 colors,back 2 colors,colour and lustre is bringht beautiful for better result,and printing black and better

white.

* It is used for flexo label printing in ribbons,cotton tape ,woven label, nylon tape, paper tape and ribbon tape.

Specifications

1) Flexo Printing Machine For Tapes

2) It is used for flexo label printing in ribbons;cotton tape ;woven label;nylon tape, paper

Feature:

* The printing mechanism of this series is that ink will be evenly spread-out on the ink-rollers at first,from the

ink-rollers,the ink transfers to the printing cylinder.

* The flexo photopolymer plate will collect the ink and press directly on the surface of the materials.

* The label will go through the drying process to complete the whole printing procedures.

* The printed label can reach the result of higher strong washing fastness by heating inside the H90 Automatic Temperature

Controlled Oven between 3-8 hours.

* Strong colorfastness to wash and polish,perfect colour registration,stability the different printing cylinders.

* Printing front 4 colors,back 2 colors,colour and lustre is bringht beautiful for better result,and printing black and better

white.

* It is used for flexo label printing in ribbons,cotton tape ,woven label, nylon tape, paper tape and ribbon tape.

Q1: Are you a factory or trading company?

We are established in 2000, a actual factory and manufacturer in the line of garment label printing machine and label cutting machine over 20 years.

Q2: Where is your factory located? How can I visit there?

Our factory is located in Ruian City, Zhejiang Province, China, about one hour by air from Shanghai. All our clients, from home or abroad, are warmly welcome to visit us!

Q3: Do you have a CE certificate?

For every model of machine, it has a CE certificate.

Q4: How about the payment term?

Our payment terms is 50% T/T in advance before production, the balance 50% should be paid before shipment.

Q5: How many years warranty? Can you teach us?

In usually,we given customer one years warranty for spare parts. If the engineer needs to go abroad for installation and training,the customer will bear all expenses.

Q6: What about the service after sale?

Once you have bought our machine, you can call us or email us telling us the machine problems and any questions about the machines. We will reply to you with 12 hours and help you to solve the problem.

We are established in 2000, a actual factory and manufacturer in the line of garment label printing machine and label cutting machine over 20 years.

Q2: Where is your factory located? How can I visit there?

Our factory is located in Ruian City, Zhejiang Province, China, about one hour by air from Shanghai. All our clients, from home or abroad, are warmly welcome to visit us!

Q3: Do you have a CE certificate?

For every model of machine, it has a CE certificate.

Q4: How about the payment term?

Our payment terms is 50% T/T in advance before production, the balance 50% should be paid before shipment.

Q5: How many years warranty? Can you teach us?

In usually,we given customer one years warranty for spare parts. If the engineer needs to go abroad for installation and training,the customer will bear all expenses.

Q6: What about the service after sale?

Once you have bought our machine, you can call us or email us telling us the machine problems and any questions about the machines. We will reply to you with 12 hours and help you to solve the problem.

Hot Searches