- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.04

-

Density (kg/m³ ):

-

160

-

Length:

-

3600/7200/14640mm, 7200-3600

-

Working Temperature:

-

1000-1350

-

Fiber Diameter:

-

3-5um

-

Shrinkage (1800 ℉, 3h):

-

3%(24 Hours)

-

Thermal Conductivity:

-

0.055-0.180(W.k.m.)

-

Model Number:

-

RONGSHENG

-

Brand Name:

-

RONGSHENG

-

Place of Origin:

-

Henan, China

-

Product name:

-

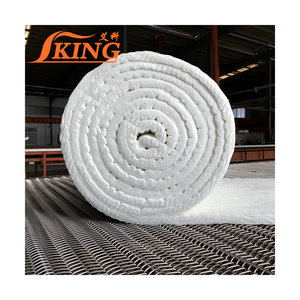

Ceramic Fiber Blanket

-

Grade::

-

HA (High Aluminum)

-

Width::

-

610

-

Ultimate Strength (≥ MPa)::

-

0.04

-

Thermal Conductivity::

-

0.09-0.16

-

Brand Name::

-

rongsheng

-

Working Temperature::

-

1000-1350

-

Density:

-

64/96/128

-

white::

-

pure white

Quick Details

-

Thickness:

-

10-50mm

-

Width:

-

610/1220mm

-

Chemical Composition:

-

AL2O3+SIO2

-

Ultimate Strength (≥ MPa):

-

0.04

-

Density (kg/m³ ):

-

160

-

Length:

-

3600/7200/14640mm, 7200-3600

-

Working Temperature:

-

1000-1350

-

Fiber Diameter:

-

3-5um

-

Shrinkage (1800 ℉, 3h):

-

3%(24 Hours)

-

Thermal Conductivity:

-

0.055-0.180(W.k.m.)

-

Model Number:

-

RONGSHENG

-

Brand Name:

-

RONGSHENG

-

Place of Origin:

-

Henan, China

-

Product name:

-

Ceramic Fiber Blanket

-

Grade::

-

HA (High Aluminum)

-

Width::

-

610

-

Ultimate Strength (≥ MPa)::

-

0.04

-

Thermal Conductivity::

-

0.09-0.16

-

Brand Name::

-

rongsheng

-

Working Temperature::

-

1000-1350

-

Density:

-

64/96/128

-

white::

-

pure white

Ceramic Fiber Blanket Properties

Ceramic Fiber Blanket is composed of long flexible, interwoven fibers manufactured by the “spun” process yielding a strong,lightweight, durable product. This material can be used for applications with temperatures from 1000°F (538°C) to 2600°F (1425°C).The product is firm, light and durable.Thermal and physical properties are retained after drying following wetting by oil, steam or water. This ceramic fiber blanket products are completely inorganic, so there are no fumes when heating for the first time.Rongsheng ceramic fiber blanket has higher tensile strength and longer service life.

Ceramic Fiber Blanket Applications

Steel Industry:

Heat treatment and annealing furnaces

Furnace door linings and seals

Furnace hot face repairs

Reheating furnace and ladle covers

Refining and Petrochemical:

Reformer and pyrolysis lining

Tube seals, gaskets and expansion joints

High temperature pipe, duct and turbine insulation

Crude oil heater linings

Power Generation:

Boiler Insulation

Boiler doors

Reusable turbine covers

Expansion seals/pipe coverings

Others:

Insulation of commercial dryers and ovens

Veneer over existing refractory

Stress relieving insulation

Glass furnace crown insulation

Fire protection

Features of Ceramic Fiber blanket

1. High tensile strength

2. Low thermal conductivity and heat storage

3. Excellent insulating performance

4. Excellent chemical stability

5. Excellent resistance to shock.

6. Good sound absorption

Ceramic Fiber blanket Specification

|

Type

|

ST

|

HP

|

HA

|

Zir-Alu

|

HZ

|

|

|

Classified Temp.

|

1260℃

(2300℉) |

1260℃

(2300℉) |

1360℃

(2480℉) |

1400℃

(2550℉) |

1430℃

(2606℉) |

|

|

Working Temp.

|

1050℃

(1922℉) |

1100℃

(2012℉) |

1260℃

(2192℉) |

1260℃

(2192℉) |

1350℃

(2462℉) |

|

|

Color

|

white

|

white

|

white

|

white

|

white

|

|

|

Density(kg/m3)

|

96/128

(6/8 lb/ft3) |

96/128

(6/8 lb/ft3) |

128/160

(8/10 lb/ft3) |

128/160

(8/10 lb/ft3) |

128/160

(8/10 lb/ft3) |

|

|

Linear Shrinkage

(%)(24 hrs,

density

128 kg/m³)

|

-3

(1000℃/1832℉) |

-3

(1100℃/2012℉) |

-3

(1250℃/2282℉) |

-3

(1200℃/2192℉) |

-3

(1350℃/2462℉) |

|

|

Thermal conductivity

(W/M.K)

Density 128kg/m³

( 8 lb/ft3)

|

0.09(

400℃/752℉) 0.16 (800℃/1472℉) |

0.09

(400℃/ 752℉) 0.16 (800℃/ 1472℉) 0.20 (1000℃/1832℉) |

0.12

(600℃/ 1112℉) 0.20 (1000℃/1832℉) |

0.132

(600℃/1112℉) 0.22 (1000℃/1832℉) |

0.16

(600℃/ 1112℉) 0.20 (1000℃/1832℉) |

|

|

Tensile Strength(Mpa)

(Density 128kg/m³) |

0.08-0.12

|

0.08-0.12

|

0.08-0.12

|

0.08-0.12

|

0.08-0.12

|

|

|

Chemical

(%)

|

Al2O3

|

46

|

47-49

|

52-55

|

45-46

|

39-40

|

|

Al2O3+

SiO2

|

97

|

99

|

99

|

-

|

-

|

|

|

Al2O3+

SiO2

+ZrO2

|

-

|

-

|

-

|

99

|

||

|

ZrO2

|

-

|

-

|

-

|

5-7

|

15-17

|

|

|

Fe2O3

|

<1.0

|

0.2

|

0.2

|

0.2

|

0.2

|

|

|

Na2O+

K2O

|

≤0.5

|

0.2

|

0.2

|

0.2

|

0.2

|

|

|

Size(mm)

|

7200/3600*610/1220/10-50mm or customized as your specification

24′/12′ * 24"/48" * 0.4"/2" |

|||||

|

Thermal conductivity Kcal/mh °C (W/mK) ,ASTM C201

|

||||

|

260 blanket

|

64 kg/m3

|

96 kg/m3

|

128 kg/m3

|

160kg/m3

|

|

mean 400°C

|

0.13

|

0.12

|

0.07

|

0.09

|

|

mean 600 °C

|

0.21

|

0.17

|

0.12

|

0.14

|

|

mean 800°C

|

0.30

|

0.25

|

0.16

|

0.20

|

|

1400 blanket

|

128 kg/m3

|

160kg/m3

|

||

|

mean 600 °C

|

0.13

|

0.14

|

||

|

mean 800 °C

|

0.20

|

0.20

|

||

|

mean1000 °C

|

0.29

|

0.28

|

||

Q1: Is your manufacturer or trader?

A1: Manufacturer, some time we help our clients to purchase relevant products as a trader.

Q2: What’s the MOQ?

A2. No limitation.

Q3: Can we visit your factory?

A3: Of course ,welcome at any time,seeing is believing

Q4: What’s your payment terms?

A4: Negotiation

Q5: Is your company accept customization?

A5: Professional technology teams and engineers all can satisfy you.

Q6: How do you guarantee quality?

A6: For every production processing,we have complete QC system for the chemical composition and Physical properties.After production,all the goods will be tested ,and the quality certificate will be shipped along with goods.

Q7: Does your supply samples?

A7: Yes, we can supply samples for free, and the freight will be undertaken by clients.