- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3200*2280*1570

-

Year:

-

2022

-

Power (kW):

-

10 kW

-

Weight (KG):

-

1100 KG

-

Cutting Material:

-

Rubber, Cork, Graphite, Felt, Asbestos, PTFE, etc.

-

Cutting thickness:

-

1-100mm

-

Working Area:

-

1600mmX2500mm

-

Pump power:

-

7.5KW/9KW

-

Format Supported:

-

DXF,PLT

-

After-sales Service Provided:

-

Free accessories, detailed tutorials, online guidance

-

Motor:

-

Japan's Mitsubishi servo motor

-

Function:

-

Cutting, milling, punching, marking, beveling

-

Advantage:

-

Double motor drive; 2. French Schneider Electric;

Quick Details

-

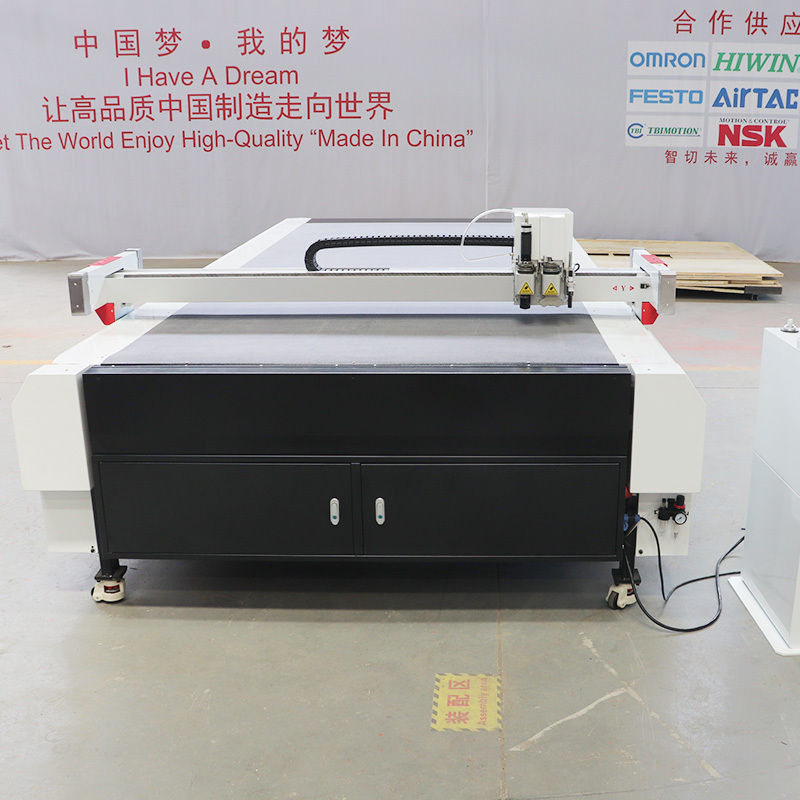

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AMOR

-

Voltage:

-

220V, 220V 380V±10%,50HZ

-

Dimension(L*W*H):

-

3200*2280*1570

-

Year:

-

2022

-

Power (kW):

-

10 kW

-

Weight (KG):

-

1100 KG

-

Cutting Material:

-

Rubber, Cork, Graphite, Felt, Asbestos, PTFE, etc.

-

Cutting thickness:

-

1-100mm

-

Working Area:

-

1600mmX2500mm

-

Pump power:

-

7.5KW/9KW

-

Format Supported:

-

DXF,PLT

-

After-sales Service Provided:

-

Free accessories, detailed tutorials, online guidance

-

Motor:

-

Japan's Mitsubishi servo motor

-

Function:

-

Cutting, milling, punching, marking, beveling

-

Advantage:

-

Double motor drive; 2. French Schneider Electric;

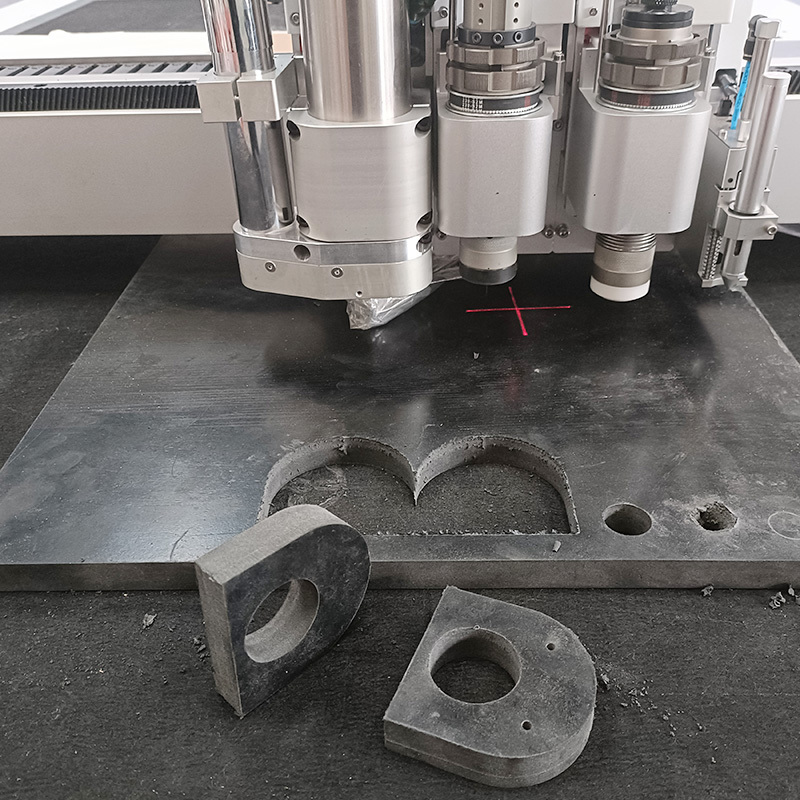

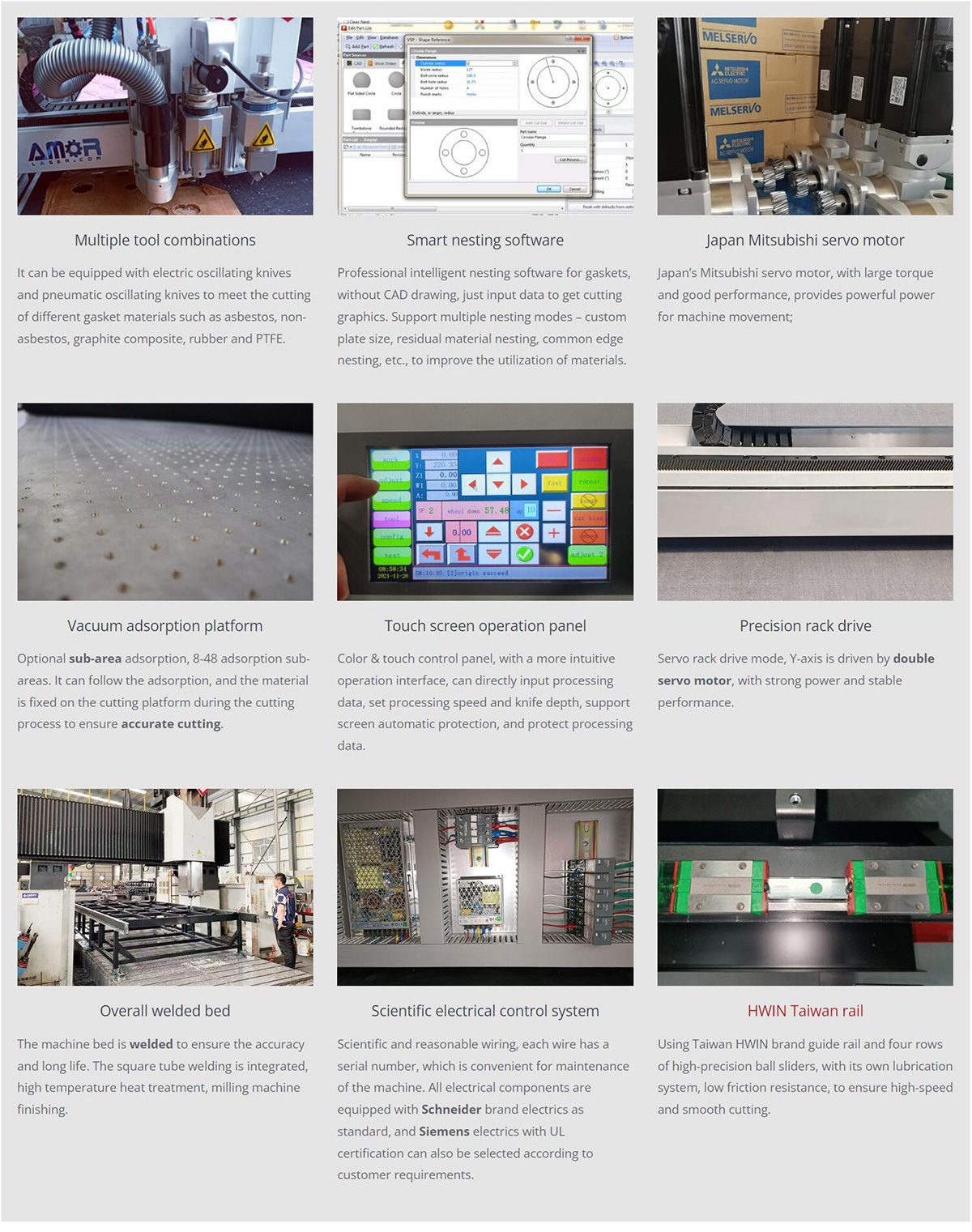

Products Description

Cutting the gasket with CNC oscillating knife cutter has 4 advantages:

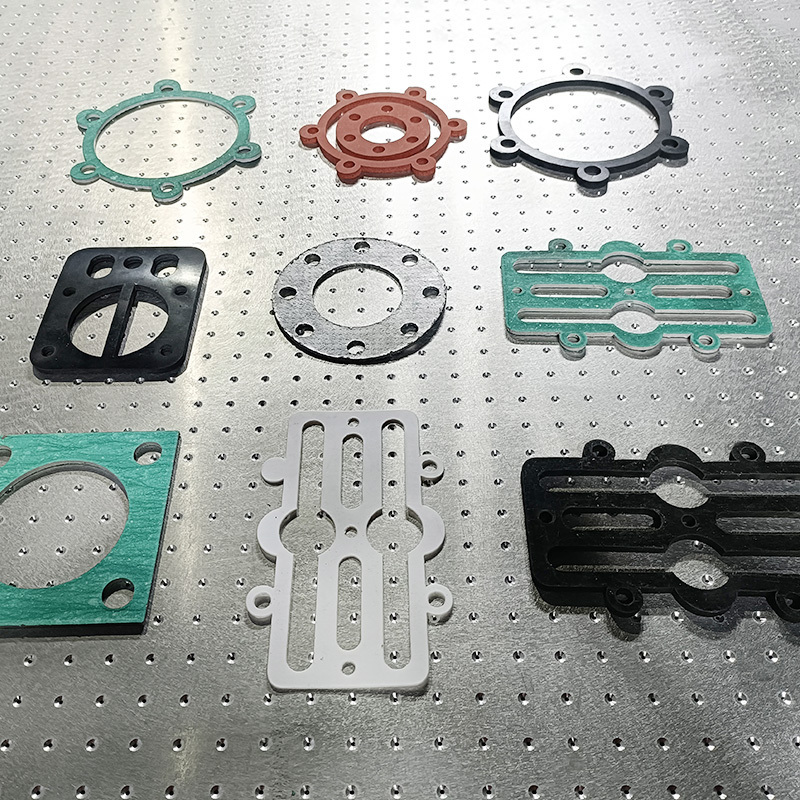

1. More flexible; the gasket automatic cutting machine does not need a mold, only need to import the processing data (PLT, DXF, AI format) into the system, can cut, and can modify the size and shape of the gasket.

2. Save materials; automatic nesting software can complete typesetting quickly and accurately, without manual nesting. After actual testing, using an automatic cutter saves more than 10% of material compared to manual cutting.

3. Guarantee product quality; CNC cutting is more precise and meets the high-precision cutting requirements of sealing gaskets.

4. Reducing the dependence of production on labor; CNC gasket cutting machine operation is very simple, low requirements for workers, solving the problem of high worker costs and difficulty in recruiting workers.

|

Model

|

AMOR-1625MK(Support customization of different sizes)

|

|

|

|

|||

|

Working area

|

1600mmX2500mm

|

|

|

|

|||

|

Tool combination

|

01. Milling cutter + high-power pneumatic oscillating tool (POT&EOT);

02. Milling cutter + electric oscillating tool (EOT & POT) +beveling cutter (or creasing);

03. Milling cutter + driving wheel cutter + vibrating cutter + inkjet + punching

|

|

|

|

|||

|

Safety devices

|

Safety devices use infrared sensing, safe and reliable

|

|

|

|

|||

|

Cutting speed

|

200-1500mm/s

|

|

|

|

|||

|

Cutting thickness

|

Standard model cutting height ≤45mm (according to the density and hardness of the cutting material)

|

|

|

|

|||

|

Applicable materials

|

It is used to cut all kinds of customized non-metal gaskets, such as: polyurethane board, epoxy board, nitrile rubber board,

neoprene rubber board, PTFE board, asbestos board, graphite composite board and silicone board, etc. |

|

|

|

|||

|

Material fixing method

|

Vacuum partition adsorption

|

|

|

|

|||

|

Transmission system

|

Mitsubishi servo motor + precision reducer + Taiwan HIWIN guide rail + grinding precision rack.

|

|

|

|

|||

|

Rated power

|

9.5KW-11KW

|

|

|

|

|||

|

Rated voltage

|

380V±10%/220V±10% optional

|

|

|

|

|||

|

Support file format

|

AI, PLT, DXF,

|

|

|

|

|||

|

Supported languages

|

English, Spanish, Chinese...

|

|

|

|

|||

|

Transfer method

|

Network port

|

|

|

|

|||

Sample Display

Our Advantages

With the continuous development of numerical control technology, more and more gasket production plants have chosen to use intelligent cutting equipment instead of workers. CNC oscillating knife cutting machine is a kind of CNC machining equipment widely used in the sealing industry. It adopts advanced oscillating knife cutting technology and can choose different tools according to materials. It can meet the cutting of non-metallic gaskets such as asbestos sheet, asbestos rubber sheet, graphite composite sheet, rubber, and PTFE.

Exhibition

Delivery Process

FAQ

1. Q: Are you a factory or Trading company?

A: We are a professional oscillating knife cutting machine production factory, only producing high-end quality CNC cutting machines.

2. Q: Can you customize the machine according to my needs?

A: Yes, we accept the customized machine, our company has an experiencedprofessional

design team, we can give you our professional suggestions according to your requirements

and design a cost-effective machine for your needs.

3. Q: What is the difference between your product and the laser cutting machine?

A: a. Our products are cut with vibrating blades, no laser, no pollution, and create a good

working environment for workers.

b. Blade cutting can ensure the edge of material cutting smooth without burning.

4. Q: What's the warranty policy?

A:Standard warranty is 36 months upon delivery.

Main parts are free of charge(except consumable parts) when problems happened because of quality problem during this period.

Problems caused by wrong operate will also well-solved.

5. Q: Can I still get support after warranty?

A: Of course, AMOR offers life-time technology support, you can always counting on AMOR service.

6. Q: This is the first time I buy machine from China, what can you do for me?

A: AMOR supply DDU service for the new buyers. This service means AMOR will deliver machine directly to your factory.

Hot Searches