- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

30

-

Range of Spindle Speed(r.p.m):

-

500 - 3000 r.p.m

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Bunkin

-

Voltage:

-

110V/220V/380/415/460V/480V

-

Dimension(L*W*H):

-

1550*1000*1700mm

-

Weight (KG):

-

850 KG

-

Marketing Type:

-

Hot Product 2023

-

Pre-sales consultation:

-

Product video, live broadcast, technical online support & design

-

Product certification:

-

ISO9001/CE

-

Solvent system:

-

water-based and oil-based

-

Zirconium ball size:

-

1.2-3.0mm

-

Optional materials:

-

polyurethane, tungsten carbide, silicon carbide, zirconium oxide

-

Structure type:

-

disc type, rod pin type, turbine type

-

Grinding chamber capacity:

-

10-100L

-

Power range:

-

11-75KW

-

Complete production unit:

-

dispersion & mixing tank, visco & fineness meter, PLC

-

After-sale technical support:

-

Online/Video tech support, spare part, maintainance & repair service

Quick Details

-

Output (kg/h):

-

300 - 800 kg/h

-

Feeding Size (mm):

-

0.1 - 0.5 mm

-

Output Size (mesh):

-

1000 - 4000 mesh

-

Power (kW):

-

30

-

Range of Spindle Speed(r.p.m):

-

500 - 3000 r.p.m

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Bunkin

-

Voltage:

-

110V/220V/380/415/460V/480V

-

Dimension(L*W*H):

-

1550*1000*1700mm

-

Weight (KG):

-

850 KG

-

Marketing Type:

-

Hot Product 2023

-

Pre-sales consultation:

-

Product video, live broadcast, technical online support & design

-

Product certification:

-

ISO9001/CE

-

Solvent system:

-

water-based and oil-based

-

Zirconium ball size:

-

1.2-3.0mm

-

Optional materials:

-

polyurethane, tungsten carbide, silicon carbide, zirconium oxide

-

Structure type:

-

disc type, rod pin type, turbine type

-

Grinding chamber capacity:

-

10-100L

-

Power range:

-

11-75KW

-

Complete production unit:

-

dispersion & mixing tank, visco & fineness meter, PLC

-

After-sale technical support:

-

Online/Video tech support, spare part, maintainance & repair service

Products Description

Horizontal sand mill

(

Pin Type

)

The pin sand mill is a closed wet grinding equipment with continuous working mode. The equipment is easy to operate, reliable, and complete in specifications. It is one of the commonly used wet grinding equipment on the market. The performance and structure are very mature.

The sealing structure adopts double-end mechanical seal cooling system, which has reliability and durability, with temperature and pressure monitoring and protection to ensure product quality.

The use of zirconia beads has the advantages of high grinding efficiency, good grinding fineness, wide application range and good wear resistance.

Product Characteristics

1.Low energy consumption ratio and high cost performance

The equipment drive uses a motor to transmit power to the main shaft through easy to start large and small pulleys. The stirring rod adopts a special zirconia structure, which is a more cost-effective product in the grinder equipment while brings efficiency with low power consumption.

2.Easy to operate and clean

The equipment is equipped with an on-site operation box and the frame. The integrated design is easy to operate. It has a bead bucket and the grinding cavity connected to the frame. It is equipped with a pulley device to separate the cylinder. The cavity and zirconium beads can be effectively cleaned for different colors and varieties.

3.Stable security monitoring

The special cooling water jacket outside the grinding chamber has a good cooling effect when the equipment is running. The conventional temperature rise is less than 10º. The equipment has temperature and pressure monitoring to set the "protection value" to ensure product quality.

4.Complete specifications and non-standard customization

The equipment specifications are from 10L to 100L, and the specifications can be customized non-standard explosion-proof type.

Technical Parameters

|

Model

|

Power

|

Rotating Speed

|

Chamber Volume

|

Throughout(L/H)

|

Bead Size

|

Fineness

|

|

WS-20L-B

|

15KW

|

1100rpm

|

20L

|

100-200

|

1.4mm-1.6mm

|

0.2μm

|

|

WS-30L-B

|

18.5KW

|

1100rpm

|

30L

|

150-400

|

1.4mm-1.6mm

|

0.2μm

|

|

WS-40L-B

|

22Kw

|

1000rpm

|

40L

|

200-600

|

1.4mm-1.6mm

|

0.2μm

|

|

WS-50L-B

|

30Kw

|

900rpm

|

50L

|

300-800

|

1.4mm-1.6mm

|

0.2μm

|

|

WS-60L-B

|

37Kw

|

900rpm

|

60L

|

400-1000

|

1.4mm-1.6mm

|

0.2μm

|

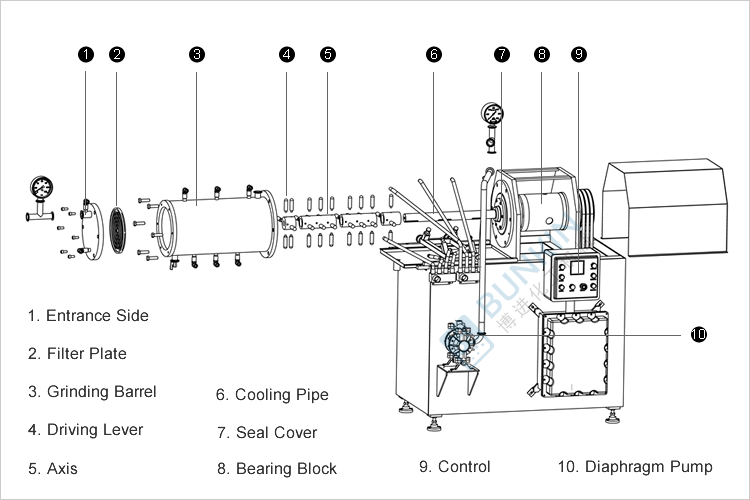

Components & Features

Products Display

Packaging & Shipping

FAQ

1.What kind of machines can you supply to customer?

We manufacture various kinds of wet milling chemical machines like basket mill, high shear mixer, horizontal bead mill, inline high shear emulsifying pump, three roll mill, multi-function kettles, etc. It is widely used for paints and coating,printing inks, adhesives, cosmetics, fertilizers, liquid detergent, flavors & fragrances and liquid agrochemical products.

2.What's the material of your machine?

The standard material of our machine is SUS304, according to the medium and requirements of customer material can be customized by SUS316 or rubber coating.

3.Why your machine similar with other supplier?

We are manufacturer and had been in this industry for more than 10 years. We design machines with advanced technology and built it as per customer requirement. We believe in service, performance and quality rather than appearance.

4. How to choose the model?

In order to select a machine according to you desire, kindly advise the mixing media, dimension of tank, type and other special technical data, then we will design and choose the suitable model for you.

5.What services do you offer?

We provide OEM service and also offer the specific product you need.

Contact Us

Over 20 Years, Bunkin mainly focused on chemical equipment's and machinery to provide fluids homogenizing, emulsifying, dispersing, homogenization, grinding, mixing, filling and related equipment's We provide solutions, one step shop. Our services are design, manufacturing, sales, installation and after-sales services.

Email: info@bunkinchina.com

Hot Searches