- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

As per Model

-

Dimension(L*W*H):

-

Custom Made

-

Weight (T):

-

1.8 T

-

Power (kW):

-

10

-

Suitable Metal:

-

Non Ferrous Metals

-

Loading Capacity:

-

300 Kgs Per Batch

-

Crucible:

-

Silicon Carbide Made

-

Certification:

-

ISO9001:2008

-

Color:

-

Support Customzied

-

Fuel:

-

Gas Fired

-

Duty cycle:

-

Continuous Work

-

Advantage:

-

High Effciency

Quick Details

-

Place of Origin:

-

Haryana, India

-

Marketing Type:

-

New Product 2023

-

Brand Name:

-

Indotherm Equipment Corporation

-

Voltage:

-

As per Model

-

Dimension(L*W*H):

-

Custom Made

-

Weight (T):

-

1.8 T

-

Power (kW):

-

10

-

Suitable Metal:

-

Non Ferrous Metals

-

Loading Capacity:

-

300 Kgs Per Batch

-

Crucible:

-

Silicon Carbide Made

-

Certification:

-

ISO9001:2008

-

Color:

-

Support Customzied

-

Fuel:

-

Gas Fired

-

Duty cycle:

-

Continuous Work

-

Advantage:

-

High Effciency

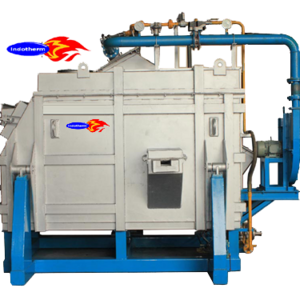

Salt Bath Furnace

Indotherm Equipment Corporation manufactures Salt-Bath Furnaces for Heat Treatment of Steel or radiance Metals. We can supply Electrically Heated as well as Gas-operated furnace as per customer needs.

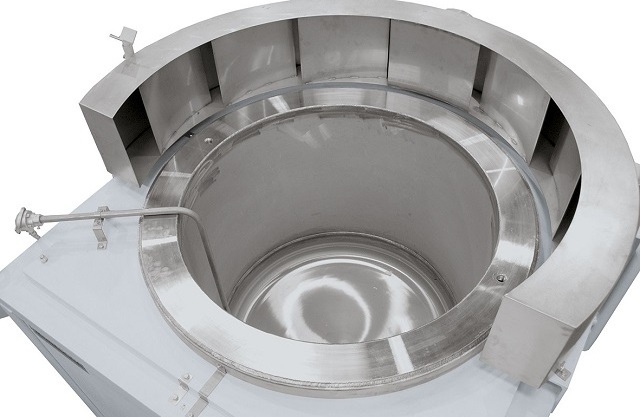

Our salt bath furnace is made out of High Quality refractory from repeated brands and nicely welded with mild steel metal sheet. Our Manufactured SS pot, crucible is tested ultrasonically before it is filled with molten salt into which work is immersed for either heating or cooling. Our manufactured crucible pot is capable of handling heavy salts such as nitrates, nitrites, caustic soda, chlorides, carbonates, and cyanide.

Our Custom made Furnaces can be operated temperatures from 500 Degree C -1200 Degree C

Salt Bath Furnace Model:

IEC-300 KG Per Batch

Maximum Temperature:

1050 Degree C

| Model |

T max

[°C] |

Effective dimensions

crucible [mm] Ø x height |

Volume

[l] |

Outer dimensions

[mm] [width x depth x height] |

Power

[kW] |

Voltage

[V] |

Weight

[kg] |

| SB 20 | 1000 | 230 X 440 | 20 | 950 X 950 X 790 | 24 |

400 3/N |

600 |

| SB 40 | 1000 | 360 X 500 | 40 | 1020 X 1020 X 880 | 28 |

400 3/N |

750 |

| SB 80 | 1000 | 550 X 550 | 80 | 1120 X 1120X 940 | 54 |

400 3/N |

850 |

| SB 150 | 1000 | 500 X 850 | 150 | 1210 X 1210 X 1250 | 68 |

400 3/N |

1200 |

| SB 180 | 1000 | 700 X 800 | 180 | 1380 X 1380 X 1250 | 72 |

400 3/N |

1250 |

| SB 240 | 1000 | 600 X 1050 | 240 | 1380 X 1380 X 1350 | 88 |

400 3/N |

1450 |

| SB 360 | 1000 | 800 X 1100 | 360 | 1470 X 1470 X 1450 | 110 |

400 3/N |

1580 |

Since its establishment in 1991, Indotherm Equipment Corporation has focused on manufacturing, exporting, and supplying high-standard furnaces and belt conveyors. As an ISO 9001:2008 certified firm, our product range includes Crucible Furnace, Rotary Furnace, Hydraulic Tilting Furnaces, Reverberatory Furnaces, and Tilting Reverberatory Furnaces. Our primary objective is to provide products that prioritize safety and environmental friendliness, with a notable emphasis on energy-saving capabilities and reduced fuel consumption.

To ensure product quality, we maintain a directory of authorized vendors and conduct thorough research to select reliable suppliers. The raw materials undergo stringent quality checks by both the vendors and our own quality tests, ensuring compliance with industry standards. Our commitment to quality has garnered praise from clients, enabling us to establish a strong market position based on exceptional service and top-notch products.

Equipped with cutting-edge machinery, our packaging unit ensures secure export and delivery of products worldwide. Our dedicated team stays updated with the latest technology, enabling us to deliver high-class products. Under the guidance of Mr. C. L. Tripathi, who prioritizes customer satisfaction and environmental safety, we continuously strive to deliver superior, energy-efficient products. Indotherm Equipment Corporation is committed to providing high-quality products, advancing the aluminum industry, and maintaining customer satisfaction.

Overall, Indotherm Equipment Corporation is dedicated to delivering high-quality products, maintaining customer satisfaction, and contributing to the advancement of the aluminum industry.