- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

UNIQUE

-

Voltage:

-

380v

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight:

-

100000 kg

-

Product name:

-

Concrete Culvert Mold

-

Control system:

-

Touch screen control

-

Pipe shape:

-

round or special shaped

-

Pipe diameter:

-

customized

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

ISO9001/CE

Quick Details

-

Pipe Material:

-

CONCRETE, cement

-

Production Capacity:

-

customized

-

Place of Origin:

-

China

-

Brand Name:

-

UNIQUE

-

Voltage:

-

380v

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight:

-

100000 kg

-

Product name:

-

Concrete Culvert Mold

-

Control system:

-

Touch screen control

-

Pipe shape:

-

round or special shaped

-

Pipe diameter:

-

customized

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

ISO9001/CE

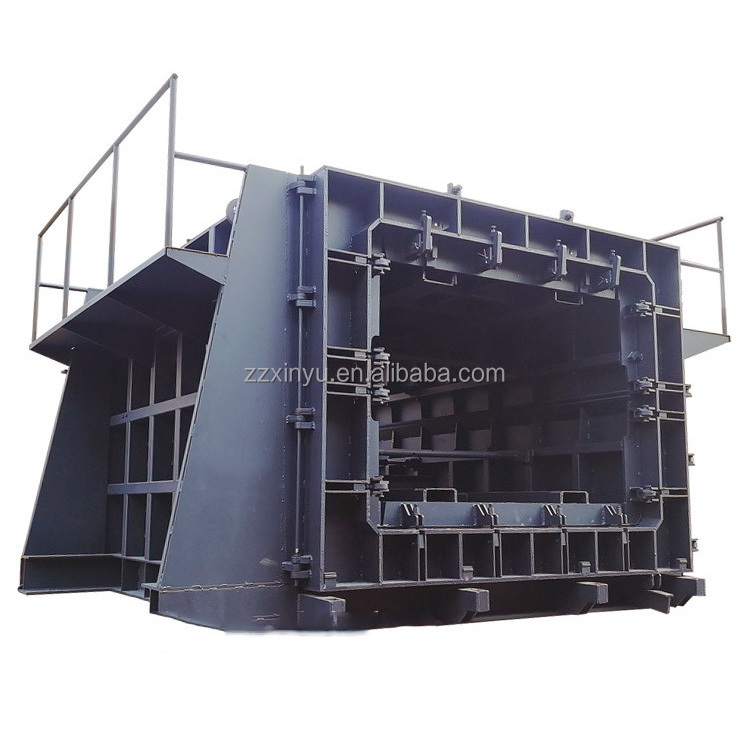

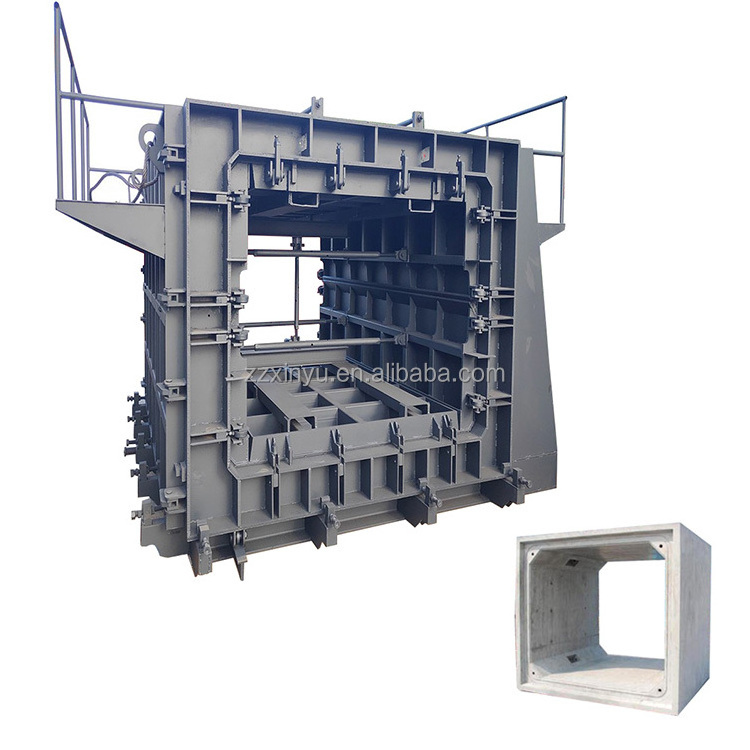

Precast Concrete Box Culvert Mould

include: Inner mould,outer mould,chassis,and vibrator.

Forming ways: Pouring wet concrete and vibrating forming

Demould ways: outer mold automatic push and pull. inner mold automatic contraction. whole production process don't need any one bolt

Maintenance: Natural maitenance or steam curing

Vibrating time:10~20minutes per set

| concrete box culvert | concrete U shaped culvert | Concrete drainage culvert | underground pass |

| customized dimension | customized dimension | customized dimension | customized dimension |

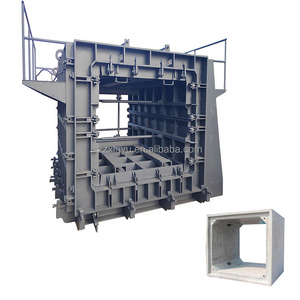

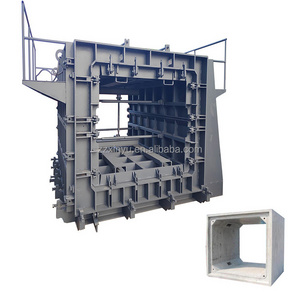

Features of

Square Culvert Mould

:

1. The inner mold adopts an automatic telescopic structure, so that the inner mold can be contracted and expanded with a light lifting device. This process is simple, efficient, reliable, and highly sealed. It is currently domestic and worldwide. The most advanced technology;

2. The outer mold adopts the form of built-in pull-out rail. The rail of the outer mold goes deep into the chassis, and one end of the track supports the outer mold, so that the outer mold can be combined and separated accurately and reliably, which is simple, practical and efficient; the built-in guide rail adopts a fully enclosed form. Will enter mortar and debris;

3. All the internal and external molds adopt quick-locking device, without a screw, it is convenient and efficient to disassemble and assemble the mold; it greatly improves the disassembly efficiency of the mold.

Xinyu Machine company has independent R&D and design capabilities, and can design and manufacture the most competitive equipment and production lines for customers based on customer needs and combined with various production processes.

Our company has more than 30 years of experience in cement products and building materials machinery manufacturing, and rich practical experience , The product is humanized. We not only have good sales in the domestic market, but also exported to Russia, Kazakhstan, Mongolia, and Viet Nam and other 20 countries.

Concrete Pipe Making Machine:

Q1: Are you trading company or manufacturer?

A: We are manufacturer.

Q2: How long is your delivery time?

A: Generally it is 3-7 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q3: What is your payment method?

A: 30% of total price should be paid by T/T as down payment; 70% balance payment should be paid by T/T before delivery.

Q4: Do you have CE certificate for your concrete pipe making machine?

A: Yes, we have certificated by CE.