- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220v, customed, 380v/50hz

-

Key Machines:

-

potato starch processing machine, hydrocyclone station, flash dryer

-

Product Type:

-

starch

-

Name:

-

Fresh Potato Starch Manufacturing Plant & Production Line

-

Material:

-

Full stainless steel

-

Function:

-

Cassava starch production

-

Raw material:

-

Cassava, tapioca

-

Power:

-

5.5kw

-

After Warranty Service:

-

Video technical support

Quick Details

-

Machinery Capacity:

-

4T/h

-

Brand Name:

-

DOING

-

Weight:

-

500 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220v, customed, 380v/50hz

-

Key Machines:

-

potato starch processing machine, hydrocyclone station, flash dryer

-

Product Type:

-

starch

-

Name:

-

Fresh Potato Starch Manufacturing Plant & Production Line

-

Material:

-

Full stainless steel

-

Function:

-

Cassava starch production

-

Raw material:

-

Cassava, tapioca

-

Power:

-

5.5kw

-

After Warranty Service:

-

Video technical support

Fresh Potato Starch Manufacturing Plant & Production Line introduction

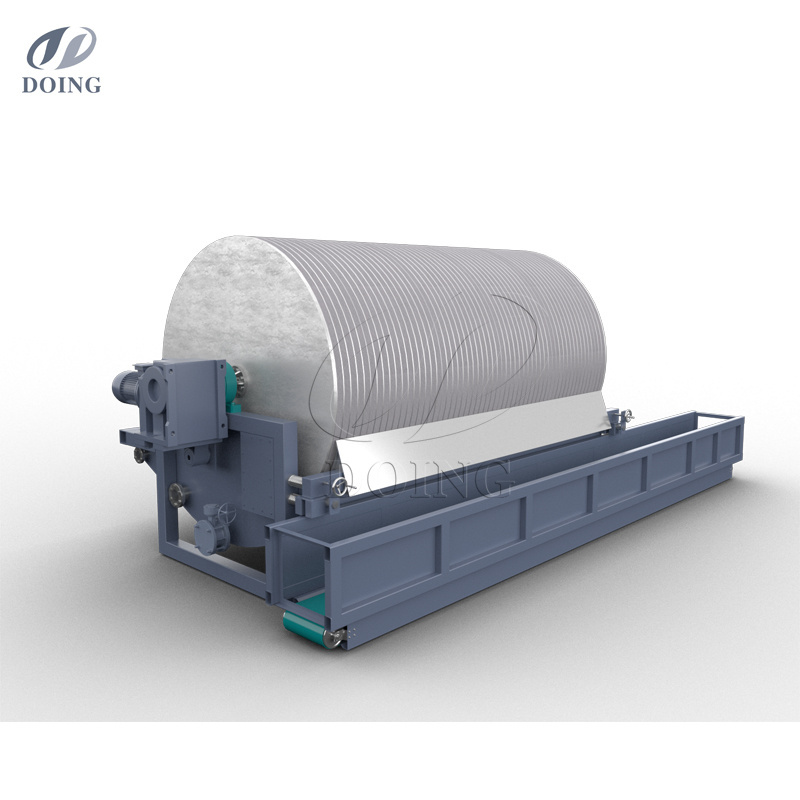

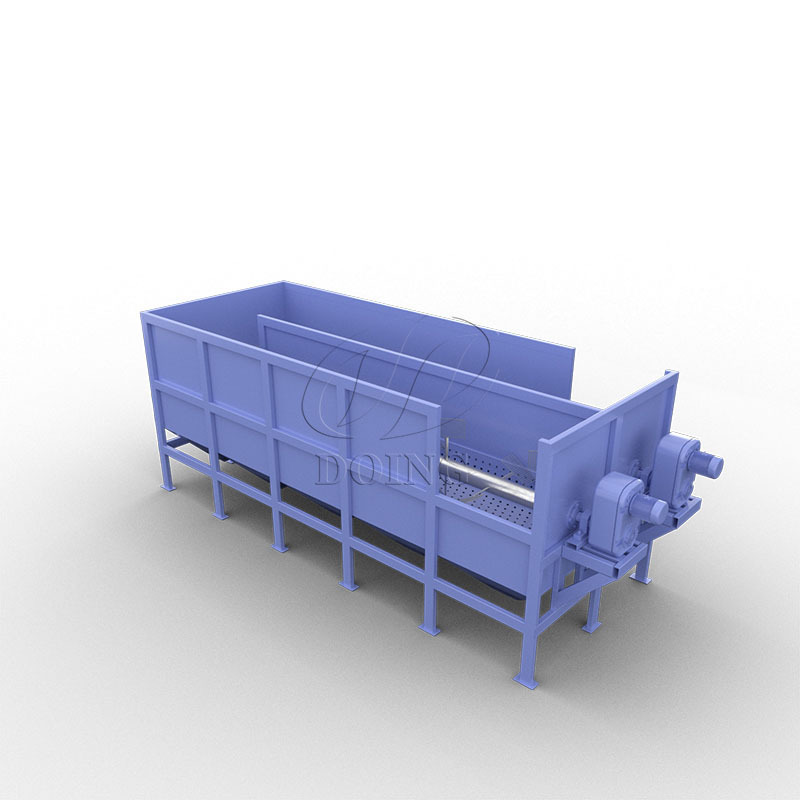

There are five major sections in

potato starch processing plant

: Washing & Crushing Sections, Screening Sections, Concentrating Sections, Drying Section and Packing Section. DOING has its own factory and entire

cassava starch processing plant

, so we can offer you the best service, production and competitive price of cassava starch processing.

Potato

starch processing plant

includes these main parts: Dry Sieve, Paddle Washing, Cutting, Rasper, Centrifuge Sieve, Fine Fiber Sieve, Hydrocyclone Station, Peeler Centrifuge, Drying Process, Packing Process.

|

Model

|

ZXS650

|

ZXS800

|

ZXS850

|

ZXS1000

|

ZXS1100

|

|

Diameter(mm)

|

650

|

800

|

850

|

1000

|

1100

|

|

Power(kw)

|

7.5-11

|

11-15

|

22-30

|

30-45

|

30-45

|

|

Weight(kg)

|

1000-1200

|

1400-1600

|

1800-2000

|

2000-2200

|

2300-2500

|

|

Model

|

DYX-362

|

DYX-438

|

DYX-516

|

|

Capacity(t/h)

|

3-4

|

5-6

|

7-8

|

|

Material

|

Stainless steel

|

Stainless steel

|

Stainless steel

|

|

Plate diameter(mm)

|

362

|

362

|

516

|

|

Power(kw/stage)

|

7.5-11

|

11-22

|

15-37

|

|

Weight(kg)

|

360

|

520

|

630

|

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1. Q: Are you a trading company or a manufacturer ?

A: We are a manufacturer, which has long experience in this industry.

2. Q: How can I get to your company ?

A: You can get a flight to CGO. We are just about 40- 50mins away from this Airport.

3. Q: How long is your guarantee ?

A: One year

4. Q: Will you send engineers to install the plant?

A: yes, but at an extra cost payable by the customer.

5. Q: Do you have some foreign customers using your equipment?

A: yes, we have our company has established business relationships with customers in Nigeria,Ghana , South Africa, Ukraine, Vietnam, Pakistan.

DOING ENGINEER TEAM