- Product Details

- {{item.text}}

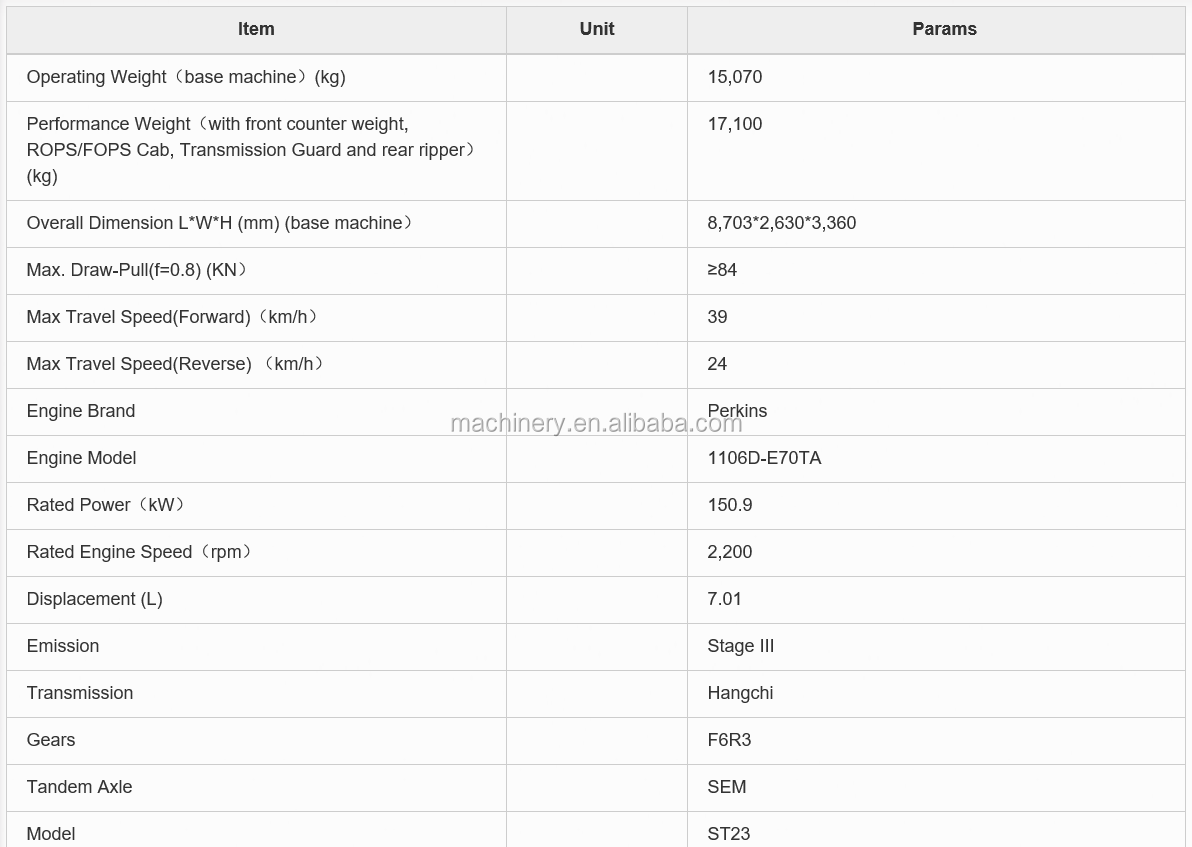

Quick Details

-

Reverse Speed(km/h):

-

25

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Maxizm

-

Weight:

-

15070 kg

-

Dimension(L*W*H):

-

8,703*2,630*3,360mm

-

Product name:

-

Top Brand 190HP Motor Grader 919 with ripper for sale

-

Rated Power:

-

140kW

-

Blade dimension (L*W*H):

-

3974*25*607 mm

-

Max. Lifting height:

-

475 mm

-

Max. cutting depth:

-

715 mm

-

Max. Drawbar:

-

78 KN

-

Wheel base:

-

6140 mm

-

Engine:

-

SDEC SC9DK190.1G3

-

Transmission type:

-

Hangchi 6WG180

Quick Details

-

Forward Speed(km/h):

-

40

-

Engine Brand:

-

SHANGCHAI

-

Working diameter:

-

6500MM

-

Reverse Speed(km/h):

-

25

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Maxizm

-

Weight:

-

15070 kg

-

Dimension(L*W*H):

-

8,703*2,630*3,360mm

-

Product name:

-

Top Brand 190HP Motor Grader 919 with ripper for sale

-

Rated Power:

-

140kW

-

Blade dimension (L*W*H):

-

3974*25*607 mm

-

Max. Lifting height:

-

475 mm

-

Max. cutting depth:

-

715 mm

-

Max. Drawbar:

-

78 KN

-

Wheel base:

-

6140 mm

-

Engine:

-

SDEC SC9DK190.1G3

-

Transmission type:

-

Hangchi 6WG180

Product Description

190HP Motor Grader 919 for Brazil with Tandem Axle

Advantages

High Productivity: Load sensing hydraulic system provides consistent and precise blade movement

High Reliability: A-frame designed drawbar provides strength in all blade positions

Comfort: World Class industry control layout with low lever efforts for reduced operator fatigue

Tandem Axle

Leveraging designing and experience on MG tandem axle

Improved bearing Layout and optimized load distribution with 4 planetary gears final drive

Less down time and reduced labor and service cost for maintenance and repairing

Longer service interval for lubrication oil change

Leading in class manufacturing and quality control level, mandatory performance testing before delivering to MG assembly line

Control System

7 position link bar with electric over hydraulic control allows ease of operation from within the cab

Optimum blade reach capability, quick DCM re-positioning for greater reach for better working on high bank side slope

The link bar is essential for extending reach capability when cutting a bank slope or back slope of a ditch

Replaceable bushings reduce service time and cost

Blade Float

Standard blade float function allows blade to lower without hydraulic pressure for increased versatility

Blade float is engaged by pushing the left and right lift cylinder controls all the way forward past the detent

Provides protection for machine and pavement during snow removal and snow plowing

Hydraulic System

Proportional Priority Pressure Compensating (PPPC) Valves contain specifically cut spools for motor grader applications,

continuously matching of hydraulic flow and pressure to power demands, allowing ease of multi-function control for optimizing working efficiency

High Reliability: A-frame designed drawbar provides strength in all blade positions

Comfort: World Class industry control layout with low lever efforts for reduced operator fatigue

Tandem Axle

Leveraging designing and experience on MG tandem axle

Improved bearing Layout and optimized load distribution with 4 planetary gears final drive

Less down time and reduced labor and service cost for maintenance and repairing

Longer service interval for lubrication oil change

Leading in class manufacturing and quality control level, mandatory performance testing before delivering to MG assembly line

Control System

7 position link bar with electric over hydraulic control allows ease of operation from within the cab

Optimum blade reach capability, quick DCM re-positioning for greater reach for better working on high bank side slope

The link bar is essential for extending reach capability when cutting a bank slope or back slope of a ditch

Replaceable bushings reduce service time and cost

Blade Float

Standard blade float function allows blade to lower without hydraulic pressure for increased versatility

Blade float is engaged by pushing the left and right lift cylinder controls all the way forward past the detent

Provides protection for machine and pavement during snow removal and snow plowing

Hydraulic System

Proportional Priority Pressure Compensating (PPPC) Valves contain specifically cut spools for motor grader applications,

continuously matching of hydraulic flow and pressure to power demands, allowing ease of multi-function control for optimizing working efficiency

World-class variable displacement piston pump, efficiently reduces power consumption and hydraulic system heat, improving fuel efficiency

Load-sensing hydraulic system provides consistent and precise blade movement, improving finishing performance

Inboard lock check valves within PPPC, prevents inadvertent cylinder movement and potential leaks Drawbar

A-frame tubular design drawbar provides maximum strength and durability

Replaceable drawbar draft ball (bolted – not welded) for less service time and cost

Easy removal of wear shims to adjust drawbar

Front Frame

Flanged box section design removes welds from high stress areas, improving reliability and durability

Continuous top and bottom plate construction provides consistency and strength, improving front frame durability

Hydraulic hose routing minimizes exposure to damage and provides quick access for service

Maintenance-free bushings improve durability and reduce overall service cost

Control Layout

Short throw levers are efficiently spaced, allowing ease of multi-function control

Short lever travel (40mm) with low lever effort reduces operator fatigue

All Wheel Drive (922 AWD)

All wheel drive (AWD) function designed for poor underfoot applications (snow, sand, gravel, mud, etc.)

Infinitely variable speed pumps and two-speed motors maximize torque in each gear delivering the most power to the ground

Exclusive steering compensation system enables a “powered turn” with improved control and a dramatic reduction of turning radius in poor underfoot conditions

Product LinkTM

Product Link™ will support your business, and accurately convey information of the equipment to relevant personnel in a timely and effective manner for your better equipment management.

Large Cab

High performance dashboard with 3 levels alarming monition system

Cab mounted on the front frame provides exceptional view to blade and front axle even during articulation

Large cab with 1.9m height and 30% larger space than most competitors, provides exceptional comfort

Load-sensing hydraulic system provides consistent and precise blade movement, improving finishing performance

Inboard lock check valves within PPPC, prevents inadvertent cylinder movement and potential leaks Drawbar

A-frame tubular design drawbar provides maximum strength and durability

Replaceable drawbar draft ball (bolted – not welded) for less service time and cost

Easy removal of wear shims to adjust drawbar

Front Frame

Flanged box section design removes welds from high stress areas, improving reliability and durability

Continuous top and bottom plate construction provides consistency and strength, improving front frame durability

Hydraulic hose routing minimizes exposure to damage and provides quick access for service

Maintenance-free bushings improve durability and reduce overall service cost

Control Layout

Short throw levers are efficiently spaced, allowing ease of multi-function control

Short lever travel (40mm) with low lever effort reduces operator fatigue

All Wheel Drive (922 AWD)

All wheel drive (AWD) function designed for poor underfoot applications (snow, sand, gravel, mud, etc.)

Infinitely variable speed pumps and two-speed motors maximize torque in each gear delivering the most power to the ground

Exclusive steering compensation system enables a “powered turn” with improved control and a dramatic reduction of turning radius in poor underfoot conditions

Product LinkTM

Product Link™ will support your business, and accurately convey information of the equipment to relevant personnel in a timely and effective manner for your better equipment management.

Large Cab

High performance dashboard with 3 levels alarming monition system

Cab mounted on the front frame provides exceptional view to blade and front axle even during articulation

Large cab with 1.9m height and 30% larger space than most competitors, provides exceptional comfort

Technical Features

•Powerful engine conforming to Stage II emission regulations

•Advanced power shift (6F/3R) transmission

•Reliable and durable three-section axle with limited slip differential

•Comfortable cab located on front frame provides great visibility and easy operation

•World class variable piston pump divides flow efficiently for lower power consumption

•Proportional, pressure compensating hydraulics provide smooth operation with increased efficiency

•Electro-Hydraulic control center-shift pin and blade linkage provide world-class blade reach and fast positioning

•Optimized blade curvature and throat clearance for increased productivity

•Unique front axle design provides optimum wheel lean and machine mobility

•Wide range of attachments to meet customer-specific job requirements

•Advanced power shift (6F/3R) transmission

•Reliable and durable three-section axle with limited slip differential

•Comfortable cab located on front frame provides great visibility and easy operation

•World class variable piston pump divides flow efficiently for lower power consumption

•Proportional, pressure compensating hydraulics provide smooth operation with increased efficiency

•Electro-Hydraulic control center-shift pin and blade linkage provide world-class blade reach and fast positioning

•Optimized blade curvature and throat clearance for increased productivity

•Unique front axle design provides optimum wheel lean and machine mobility

•Wide range of attachments to meet customer-specific job requirements

Details Images

Why Choose Us

Hot Searches