- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

600 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ESKO

-

Voltage:

-

220V / 380V / 3 Phase

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

15 kW

-

Product Name:

-

Vacuum Emulsifying Mixer

-

Mixing Speed:

-

0-65RPM

-

Mixing Type:

-

Agitator with wall scraper

-

Homogenizer Speed:

-

0-3000RPM

-

Homogenizer Design:

-

Customized

-

Material Contact Parts:

-

SUS316L

-

Heating Method:

-

Electrical Heating & Steam Heating

-

Cooling Method:

-

Water Cooling

-

Lifting System:

-

Hydraulic Lifting & Tilting System

-

Vacuum:

-

-0.1 MPa

Quick Details

-

Barrel Volume (L):

-

125

-

Max. Loading Volume (L):

-

100 L

-

Range of Spindle Speed(r.p.m):

-

0 - 65 r.p.m

-

Weight (KG):

-

600 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ESKO

-

Voltage:

-

220V / 380V / 3 Phase

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

15 kW

-

Product Name:

-

Vacuum Emulsifying Mixer

-

Mixing Speed:

-

0-65RPM

-

Mixing Type:

-

Agitator with wall scraper

-

Homogenizer Speed:

-

0-3000RPM

-

Homogenizer Design:

-

Customized

-

Material Contact Parts:

-

SUS316L

-

Heating Method:

-

Electrical Heating & Steam Heating

-

Cooling Method:

-

Water Cooling

-

Lifting System:

-

Hydraulic Lifting & Tilting System

-

Vacuum:

-

-0.1 MPa

Products Description

Vacuum Emulsifying Mixer - the solution for all your emulsifying needs. This cutting-edge machine produces high-quality emulsions with a smooth, uniform texture, making it ideal for a variety of industries.

With its advanced vacuum system and high-speed homogenizing capabilities, this mixer creates evenly blended and homogenized mixtures every time, resulting in a stable and consistent emulsion. It is also user-friendly and easy to operate, with intuitive controls and safety features for secure operations.

|

Model

|

Volume

(L)

|

Mixing Power

(KW)

|

Mixing Speed

(RPM)

|

Homogenizer

(KW)

|

Homogenizer

Speed

|

Heating Method

|

|||||

|

ES-VH5

|

5

|

0.4

|

0-63

|

0.55

|

0-3600

|

Electrical Heating or Steam Heating

|

|||||

|

ES-VH10

|

10

|

0.55

|

|

1.1

|

|

|

|||||

|

ES-VH50

|

50

|

0.75

|

|

3

|

|

|

|||||

|

ES-VH100

|

100

|

1.5

|

|

4

|

|

|

|||||

|

ES-VH200

|

200

|

2.2

|

|

5.5

|

|

|

|||||

|

ES-VH500

|

500

|

3.8

|

|

11

|

|

|

|||||

|

ES-VH1000

|

1000

|

5.5

|

|

15

|

|

|

|||||

|

ES-VH2000

|

2000

|

7.5

|

|

18.5

|

|

|

|||||

|

ES-VH5000

|

5000

|

15

|

|

22.5

|

|

|

|||||

|

Vacuum

|

Ultimate vacuum -0.1 MPa

|

|

|

|

|

|

|||||

|

Remark

|

Above parameters are for reference only, machine will be customized according to client's need.

|

|

|

|

|

|

|||||

Application Product

Details Images

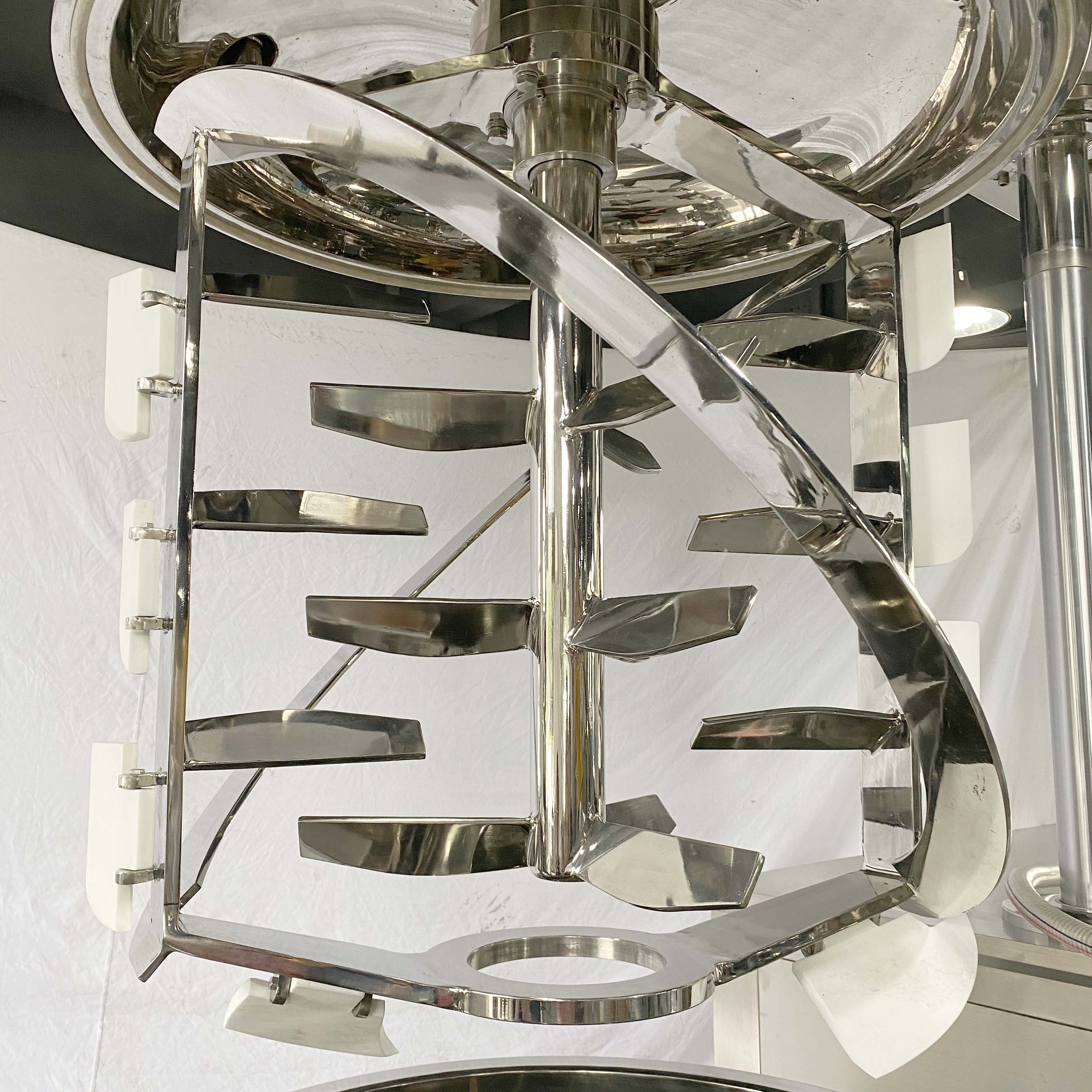

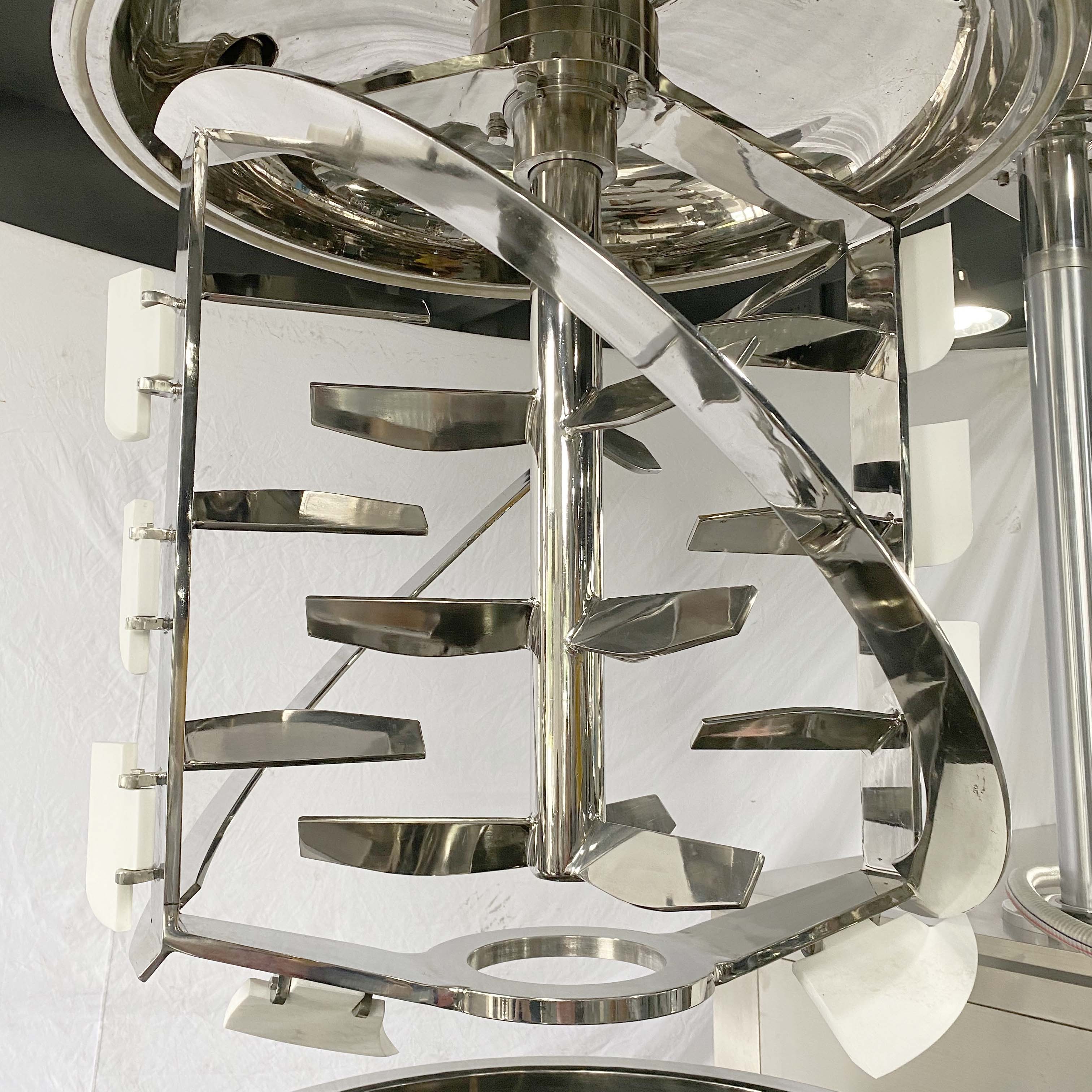

Bidirectional Mixing Paddle

The latest mixing design, with wall scraper to avoid residual, two way mixing with ribbon to roll the material, make the mixing more even.

All blade are perfectly welded on the agitator, no dead corner, easier to clean.

Unidirectional Mixing Paddle

One way mixing with two fixed paddles, with wall scraper to avoid residual.

Generally we use this design on fixed type mixer and toothpaste mixer. (Toothpaste mixer has 3 agitator in 1 tank.)

Hydraulic Tilting System

Easier and safer to operate, generally we use it for capacity above 100L.

The tilting can use for material discharging, and make the cleaning work easier.

Manual Tilting System

With a hand wheel to control and tilting system, this design is more

economical and suitable for small capacity of tank.

The tilting can use for material discharging, and make the cleaning work easier.

Botton Control Panel.

Siemens PLC Touch Screen Control.

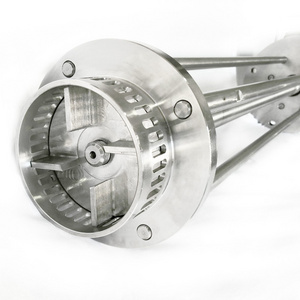

Different Homogenizer Design For Your Choice.

Esko offers different kinds of homogenizer to make different products, you can always find a suitable design here to make your product more perfect.

Click to send an inquiry, our technician will recommend you a design according to your needs.

Main Component

Complete Production Line

Recommend Products

Purchse & Production Process

Project Reference

Buyer's Comment

FAQ

Q: Are you a manufacturer / factory?

A: Yes we are a manufacturer with more than 15 years manufacturing experience in machinery.

Q: I am planning to set up a factory, but i am a green hand, could you help me with that?

A: Sure! We've been helping dozens of client to set up their new factory, generally will offer you a suitable design based on your actual situation, such as your daily production, raw material formula, factory layout, etc. What's more, we can help you to find reliable raw material and packaging supplier in China. After you received our machines, we could send our technician to your factory for installation and training your people.

Q: How long is your warranty? After warranty, what do we do if the machine breaks down?

A: Our warranty is two years, and lifelong maintenance is provided. After warranty we could still offer you online or on-site service.

Q: How do you control or test the quality before shipment?

A: Firstly, our accessories/parts supplier will test their products before they ship to us. After the machines are finished, our Quality Inspectors and Technical Team will test and run each machine, and make a testing video for our client. We'd also like to invite you come to our factory to verify machines yourself.

Q: Are the machines difficult to operate? How can we learn it?

A: Our machines are adopted with PLC smart screen control, very easy to operate. Also, we will make an operation instruction video and send it to our client before shipment, and send our technician to client's factory for trainning if needed. Moreover, we have 24 hours online service, we could have video call with you anytime to answer your questions or providing you operation guidance.

Q: Could i visit your factory to observe machine running?

A: Yes, customers are warmly welcome to visit our factory.

Q: Could you make the machine according to buyer's requirement?

A: Yes, OEM is acceptable. Most of our machines are customized according to customer's need.

Hot Searches