- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

6000*1200*1500mm

-

Year:

-

2024

-

Power (kW):

-

50 kW

-

Weight (KG):

-

9800 KG

-

capicity:

-

8-10ton

-

out put:

-

Fuel oil

-

thickness of reactor:

-

14mm or 16mm

-

quality test:

-

X-ray test

-

mode of cooling:

-

water cooling

-

safety:

-

alarm system

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CGY

-

Voltage:

-

customer demand

-

Dimension(L*W*H):

-

6000*1200*1500mm

-

Year:

-

2024

-

Power (kW):

-

50 kW

-

Weight (KG):

-

9800 KG

-

capicity:

-

8-10ton

-

out put:

-

Fuel oil

-

thickness of reactor:

-

14mm or 16mm

-

quality test:

-

X-ray test

-

mode of cooling:

-

water cooling

-

safety:

-

alarm system

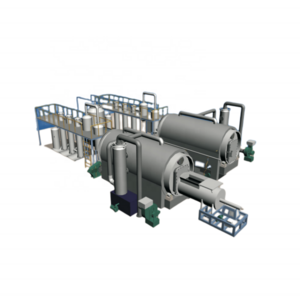

automatic waste tyre pyrolysis plant rubber recycling machine

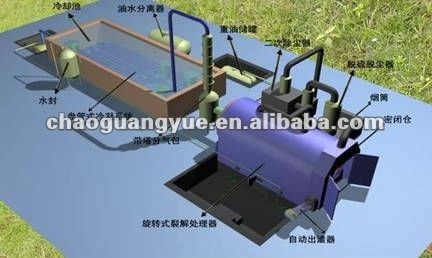

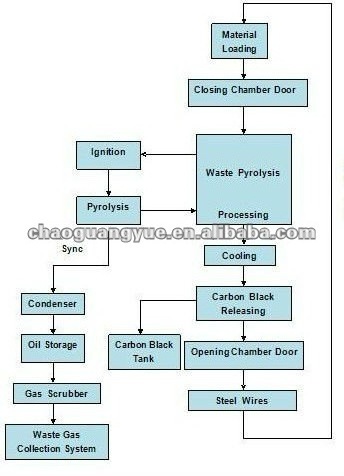

Pyrolysis plant whole process chart

1.The main parts and the function of the pyrolysis machine

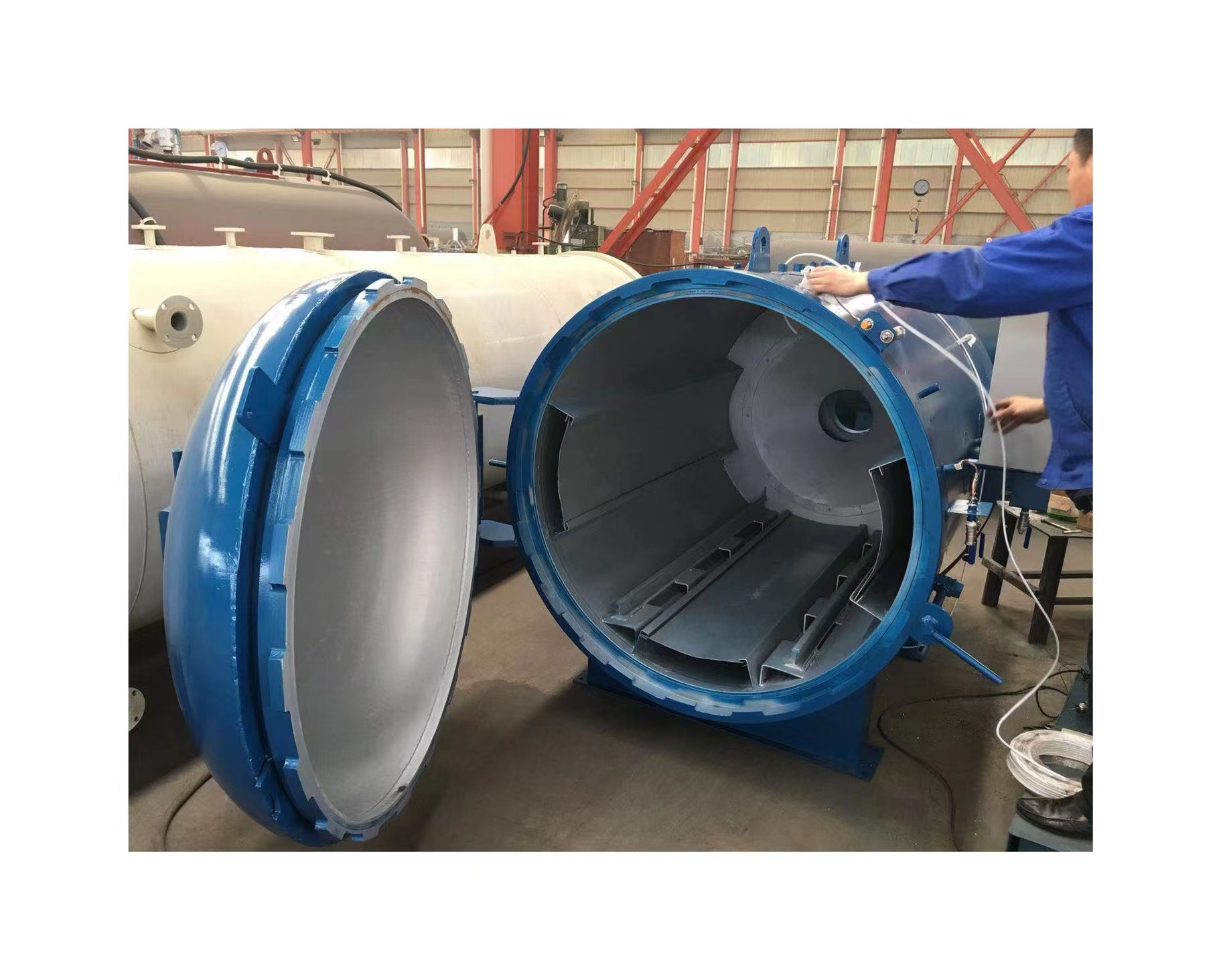

a) The reactor

The raw materials are pyrolyzed in the reactor,it is 245R boiler steel.the thickest part could be 16mm.It works doesn't like the traditional way that we burn something,we make the waste pyrolyzed at certain temperature,so it without air or water.In a word,it has the same function to kiln,so I think it’s your poitnt.

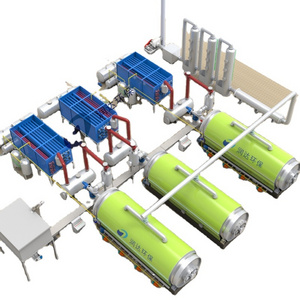

b) Oil reacting tank

The first step to deposit the waste in the tyre gas to make sure the clearness of oil.

c)Gas separate

The impurities will be deposited at the bottom of the gas separate.

d)Depositing tank

The second filter,so that the oil gas will be refined .

e)Cooling pool

The oil gas will be cooled down in the cooling pipes of the cooling pool.

f)Oil tank

It can store the crude oil.

g)mpact duster collector

The first step to purify the waste in the air.

h)Water film cyclone

The second step to clean the waste in the air .

i)Chimney

The white smoke without pollution will release into the air from the chimney .

2.The advantages of our machine

a) the material of the reactor is 16mm boiler plate,and it’s more useful than the 12mm and 14mm one.

b)The cooling tubes we use is 10tubes,the diameter is 220mm,no jamming concerns and easy to maintenance.

c)The horizontal cooling pool without electricity machine can save more electricity than vertical one.

d)3 parts to clean the waste in the gas,no pollution to the environment.

e)Recycling the waste gas as fuel to burn after 2hours.

f)Big draft fan take away the smoke slao keep the temperature in the reactor.

g)With safety valve to control the pressure to make sure the safety.

1. Material: Q245R/345R special steel plate, thickness 14-16mm

2. Welding: Automatic welding machine with heating treatment and x-ray detection will prolong the service life of reactor to the max.

3. The service life of the reactor will be 5-6 years

Energy saving

1. Well sealing for heating system, no gas leak and saving fuel.

2. The exhaust gas will be recycled for reactor heating.

Technical parameter of equipment

|

Serial No. |

Items |

Contents |

||

|

1 |

Equipment type |

WJ-5 type |

WJ-6 type |

|

|

2 |

Raw material |

Scrap rubber |

Scrap rubber |

|

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

|

|

4 |

24-hour disposal amount |

12 tons raw material |

15 tons raw material |

|

|

5 |

24-hour oil yield |

5.4 tons fuel oil |

6.75 tons fuel oil |

|

|

6 |

Operating pressure |

Constant pressure |

Constant pressure |

|

|

7 |

Rotate speed of main machine |

0.4 turn/minute |

0.4 turn/minute |

|

|

8 |

Power |

3.0kw |

3.0kw |

|

|

9 |

Mode of cooling |

Water cooling |

Water cooling |

|

|

10 |

Consumption of cooling water (T/h) |

4 |

6 |

|

|

11 |

Kind of drive |

Internal gear drive |

Internal gear drive |

|

|

12 |

Heating mode |

Hot air |

Hot air |

|

|

13 |

Mounting means |

Having base |

Having base |

|

|

14 |

Noise dB(A) |

≤85 |

≤85 |

|

|

15 |

External dimension of main machine (length×width) |

5100×2200 |

6000×2200 |

|

|

16 |

Working form |

Continuous operation |

Continuous operation |

|

|

17 |

Weight of main machine (T) |

16.5 |

21 |

|