3D building information modeling software used in the building and construction industries for steel and concrete detailing, we make this model for customer to create and manage 3D structural models in concrete or steel, and guides them through the process from concept to fabrication.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

China

-

Model Number:

-

Q345

-

Surface treatment:

-

painted or galvanized

-

steel column and beam:

-

welded H section steel

-

wall cladding:

-

steel sheet

-

purlin:

-

galvanized C section steel

-

Material:

-

Q345 Q235

-

Usage:

-

50 Years

-

Roof and wall material:

-

Rock Wool Sandwich Panel,single steel sheet.Eps sandwich pannel

-

Color:

-

Customized

Quick Details

-

Grade:

-

steel structure

-

Tolerance:

-

±1%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

China

-

Model Number:

-

Q345

-

Surface treatment:

-

painted or galvanized

-

steel column and beam:

-

welded H section steel

-

wall cladding:

-

steel sheet

-

purlin:

-

galvanized C section steel

-

Material:

-

Q345 Q235

-

Usage:

-

50 Years

-

Roof and wall material:

-

Rock Wool Sandwich Panel,single steel sheet.Eps sandwich pannel

-

Color:

-

Customized

Prefab steel warehouse design quality guarantee hot sale steel structure

steel structure warehouse components :

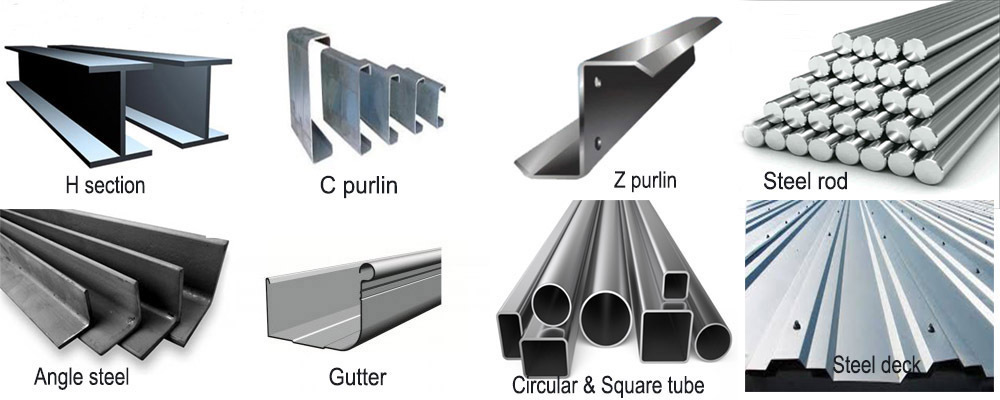

Steel structure is a new type of building structure system, which is formed by the main steel framework linked by H-section, Z-section, and U-section steel components or any other product shape according to customer's requirements, roof and walls using a variety of panels and other components such as windows and doors.

Light steel structure building is widely used in warehouses, workshops, large factories, commercial building, car parking system, agricultural storage shed, livestock house, poultry house and so on.

|

Item name

|

Steel structure building specifications

|

|

main steel frame

|

H section steel beam and comlumns, painted or galvanized, galvanized C section or steel pipe

|

|

Secondary frame

|

hot dip galvanized C purlin , steel bracing , tie bar , knee brace , edge cover etc.

|

|

Roof panel

|

EPS sandwich panel , glass fiber sandwich panel , rock wool sandwich panel , and Pu sandwich panel or steel sheet

|

|

Wall panel

|

Sandwich Panel or Corrugated Steel Sheet

|

|

Tie Rod

|

Circular Steel Tube

|

|

Brace

|

Round Bar

|

|

Knee Brace

|

Angle Steel

|

|

Roof Gutter

|

Color Steel Sheet

|

|

Rainspout

|

PVC Pipe

|

|

Door

|

Sliding Sandwich Panel Door or rolling Metal Door

|

|

Windows

|

PVC/Aluminum Alloy Window

|

|

Connecting

|

post feet bolts, intensive bolt , intensive bolt

|

|

Packing

|

according to the pack list made by our engineer

|

|

Drawing

|

We can make the design and quotation according to your require or your drawing

|

Steel warehouse buildings construction photos.

Warehouse types:

First foundation work before installing the prefabricated steel structure building.

The steel materials shall be packed carefully for full protection. Specifically, main structure materials are generally loaded into 40'OT shipping containers, while sky light, ventilators, roof panels, wall panels and other accessories are loaded into 40'HC shipping containers for delivery.

Qingdao RT Steel Structure co., Ltd is located in Huangdao district of Qingdao city.It covers an area of 30 thousand square meters which is specialized in designing,manufacturing and installation of steel structure products.The company has two professional production lines, the annual output reaches 30 thousand tons.It also owns professional design team,two senior structural engineers, three senior architects, three senior engineers, sixty professional processing staffs. Our company has three-grade steel structure construction qualification and passed the ISO9000 international systems Certifications.

3D model.

Foundation plan.

We provide foundation plan for your project for free. Please just make local geological report

If you need, we would love to send the anchor bolts and mold. Before the production work finish, you can do the foundation work first.

Building installation drawing.

Free installation drawing for your project. To make the erection work more clear and easier.

Besides, we make each steel component with different mark, only refer to the drawing and pick the right one to build.

Our customers! airport pick up! facotry visiting! Office discussion!

|

Quote requirements

|

|

|

|

1

|

Size: Length*width*height _____mm*_____mm*_____mm

|

|

|

2

|

Wind load (max. Wind speed) _____kn/m2, _____km/h, _____m/s

|

|

|

3

|

Snow load (max. Snow height) _____kn/m2, _____mm

|

|

|

4

|

Thermal insulation If yes, EPS, fiberglass wool, rockwool, PU sandwich panels, Corrugated steel sheet with fiber glass wool will be suggested; If not, the Corrugated steel sheet will be ok. The cost of the latter will be much lower than that of the former.

|

|

|

5

|

Door and window quantity & size _____units, _____(width)mm*_____(height)mm

|

|

1.Are you a manufacture or trading company?

Reply: We has the right to import and export business in China , is a comprehensive and large-scale industry and trade enterprises. You are welcome to visit us for inspection at any time .

2.What are the main products your company produces?

Reply: The business scope of my company is mainly structural steel construction, such as industrial workshop, light steel mobile house, container house, warehouse, high-rise frame office building and frame structure of large equipment, etc. In addition, we also provide steel structure processing service, like the processing of H- steel, steel beam ,steel beam ,color steel plate, C-Purlin steel, Z-Purlin steel , floor deck etc.

3.What's the quality grade of the steel structure components?

Reply:Q345B is used for main steel structure, Q235B is used for secondary steel structure.

4.How about the derust grade?

Reply:Q345B is used for main steel structure, Q235B is used for secondary steel structure.

Reply: We will furnish you the detailed construction drawing and the construction manual which could help you to erect and install the building step by step.We also could send the engineer your local to help you if needed.

6.Maintenance:

Reply:Finish paint need to be done after the frame installed,and do it again after 6-8 months in order to keep the surface for a long life time.