- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

COVNA

-

Acting Mode:

-

Spring Return or Double Acting

-

Air Supply Pressure:

-

2.5 to 8bar

-

Material:

-

SS316, SS304

-

Sealing Material:

-

PTFE

-

Pressure:

-

1.6~6.4MPa

-

End Connection:

-

Flanged End

-

MOQ:

-

1 Piece

-

Brand:

-

COVNA

-

Warranty:

-

1 year

-

Function:

-

Control Flow

Quick Details

-

Port Size:

-

1/2"~6", DN15~DN150

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

HK55-F Ball Valve

-

Brand Name:

-

COVNA

-

Acting Mode:

-

Spring Return or Double Acting

-

Air Supply Pressure:

-

2.5 to 8bar

-

Material:

-

SS316, SS304

-

Sealing Material:

-

PTFE

-

Pressure:

-

1.6~6.4MPa

-

End Connection:

-

Flanged End

-

MOQ:

-

1 Piece

-

Brand:

-

COVNA

-

Warranty:

-

1 year

-

Function:

-

Control Flow

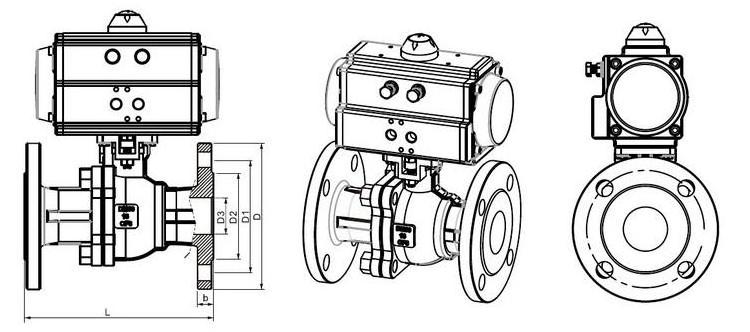

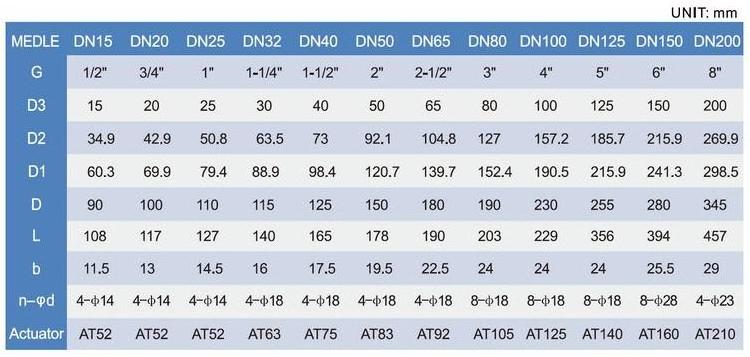

Dimension:

Actuator

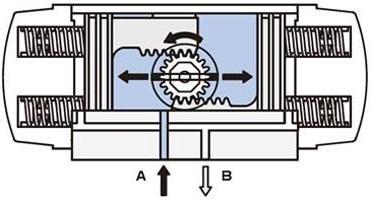

Principle of Single Acting Actuator (Spring Return)

CCW

Air to port A forces the pistons outwards, causing the springs to compress, The pinion turns counterclockwise while air is being exhausted from port B.

Loss of air pressure on port A, the stored energy in the springs forces the pistons inwards. The pinion turns clockwise while air is being exhausted from port A.

CW

Air to port B forces the pistons outwards, causing the springs to compress, The pinion turns counterclockwise while air is being exhausted from port B.

Loss of air pressure on port A, the stored energy in the springs forces the pistons inwards. The pinion turns clockwise while air is being exhausted from port A.

Principle of Double Acting Actuator

CCW

Air to Port A forces the pistons outwards, causing the pinion to turn counterclockwise while the air is being exhausted from Port B.

Air to Port B forces the pistons inwards, causing the pinion to turn clockwise while the air is being exhausted from Port A.

CW

Air to Port A forces the pistons outwards, causing the pinion to turn clockwise while the air is being exhausted from Port B.

Air to Port B forces the pistons inwards, causing the pinion to turn counterclockwise while the air is being exhausted from Port A.

Pneumatic valve FAQ

Q: What is the difference between Normally Open and Normally Closed valves?

A: As the name suggests, Normally Open valves allow air to pass when they are not energized (or actuated). Normally Closed valves must be actuated to allow air to pass.

Q: What is the life span of your pneumatic actuators?

A: We have passed 1 million times of product quality test, and obtained the certificate

Q: Does the air actuated valve have a manual override?

A: The air actuator does not have a manual override, but a manual override is provided with optional direct mount solenoid valves.

Q:How fast does an air actuated valve operate?

A: See product specifications. Generally, smaller valves less than 2 inch pipe size, cycle in about one second. Larger valves up to 6 inch pipe, cycle in about 1.5 seconds. A cycle is per 90° rotation

Q:Can I add a High Temperature kit to an existing Valworx air actuated

A:Yes, you would need to select a kit matching both the actuator and valve mounting patterns. See actuator accessories

Q:Can I mechanically adjust the flow rate of an air actuated ball valve?

A: No, but we do offer pneumatic positioners with 4-20mA or 3-15PSI inputs. Positioners allow user to adjust flow 0-100%.

Q:Can I use the air actuated ball valve outside?

A: Yes, air actuated valves are weatherproof per materials of construction. Do not exceed minimum and maximum temperature specifications.

Q:Do you have a way to confirm the air actuated valve is in the closed position? Open position?

A: Yes, we offer an optional valve monitor/limit switch box. Monitor contains (2) dry contact limit switches used to confirm open and closed position. There is also a highly visual valve position indicator.

Q:What is the maximum allowable fluid velocity?

A:Metal valves: 5 to 10 feet/second, closer to 5ft/sec is better PVC valves: < 5 feet/second

Q:Can you customize the color of the actuator?

A: We can customize different colors, LOGO and so on according to customer's requirements.