- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Tobee

-

Model Number:

-

F6147

-

Place of Origin:

-

Hebei, China

-

Structure:

-

Centrifugal Slurry Pump

-

Outlet Size:

-

18 inch

-

Power:

-

120kw

-

Size:

-

8" x 6"

-

Capacity:

-

360-828m3/h

-

Head:

-

10-61m

-

Speed:

-

500-1140rpm

-

Material:

-

Natural Rubber, Synthetic Rubber, Neoprene,etc.,

-

Product name:

-

Slurry Pumps

-

Info.:

-

Operation1(at)tobeepump(dot)com

-

Web:

-

www.tobeepump.com

-

Impeller Vane No.:

-

5

Quick Details

-

Application:

-

Biofuel Industry, Commercial Buildings, Developing World Water Solutions, District Energy, Drinking water treatment, Family Homes, Food and Beverage Industry, Industrial Boilers, Industrial Utilities, Irrigation and Agriculture, Machining, Marine, Metal and Equipment Manufacturers, Mining industry, Washing and Cleaning, Wastewater Transport and Flood Control, wastewater treatment, Water Treatment Solutions

-

Pressure:

-

Low Pressure

-

Voltage:

-

380V/460V/480V

-

Brand Name:

-

Tobee

-

Model Number:

-

F6147

-

Place of Origin:

-

Hebei, China

-

Structure:

-

Centrifugal Slurry Pump

-

Outlet Size:

-

18 inch

-

Power:

-

120kw

-

Size:

-

8" x 6"

-

Capacity:

-

360-828m3/h

-

Head:

-

10-61m

-

Speed:

-

500-1140rpm

-

Material:

-

Natural Rubber, Synthetic Rubber, Neoprene,etc.,

-

Product name:

-

Slurry Pumps

-

Info.:

-

Operation1(at)tobeepump(dot)com

-

Web:

-

www.tobeepump.com

-

Impeller Vane No.:

-

5

Product Description

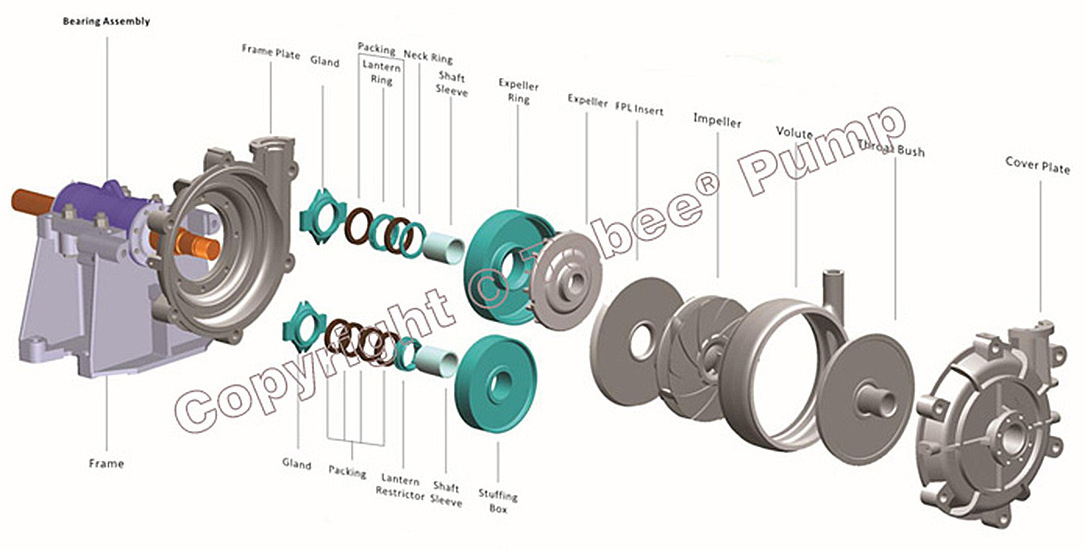

Ceramic Slurry Pump Parts F6147 on 8x6 slurry pump is a kind of inorganic nonmetallic materials and made of Silicon Nitride Bonded Silicon Carbide,aimed to wear and erosion resistant working application,such as coal power generation,non-ferrous foundry,mining etc.. As the most important pump parts of slurry pup, Slurry Pump Ceramic Impeller wear-resisting performance is 5 times of high chrome with Mohs hardness 8.9, only after Diamond and Cubic Boron Nitride. Compare with similar products, Tobee’s ceramic density is about 5% higher than others, and double flexural strength higher at normal temperature.

Why selected ceramic slurry pump parts?

1. Tobee® ceramic wetted parts of slurry pump can be 100% interchangeable with TH series slurry pump parts.

2. The corrosion and abrasion resistance of ceramic slurry pump spares are highly exceed ones made by high chrome alloy, the abrasion resistance of ceramic parts are 5 times as wearable as high chrome.

3. More resistant to corrosion than any other material, Tobee® ceramic slurry pump wearing spares could be a quite advantageous if there were solids in combination with non-neutral slurries, a leach or an acid (PH-value 0-12).

4. The weight of slurry pump ceramic spares is only 1/3 of chrome pump parts.

Tobee® 8/6 Slurry Pump Performance Parameters:

|

Model

|

Max. Power

(kw)

|

Materials

|

|

Clear Water Performance

|

|

|

|

|

Impeller Vane No.

|

|||||

|

|

|

Liner

|

Impeller

|

Capacity Q

|

Head H

(m)

|

Speed n

(rpm)

|

Eff.η

(%)

|

NPSH

(M)

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

TH8x6E

|

120

|

M

|

M

|

360-828

|

10-61

|

500-1140

|

72

|

2-9

|

6

|

|||||

APPLICATIONS

Mining & Mineral Processing

The slow running speeds of the Tobee heavy duty rubber lined slurry pump, together with the comprehensive choice of abrasion resistant alloys and rubber, provide unrivalled performance and service life for all abrasive mining and minerals processing applications.

Chemical Process

The interchangeability of alloy and rubber components in the same pump casing, together with a wide range of mechanical seals, make the Tobee heavy duty rubber lined slurry pump the most flexible choice for the chemical plant environment.

Sand & Gravel

Designed for easy and simple strip down and re-assembly, the Tobee heavy duty rubber lined slurry pump minimises downtime, making it the ideal choice where installed stand by pumps are not available.

Sugar Processing

The premium reliability and service life of the Tobee heavy duty rubber lined slurry pump is specified by many sugar plant engineers worldwide where uninterrupted pump operation during the sugar campaign is a critical requirement.

The slow running speeds of the Tobee heavy duty rubber lined slurry pump, together with the comprehensive choice of abrasion resistant alloys and rubber, provide unrivalled performance and service life for all abrasive mining and minerals processing applications.

Chemical Process

The interchangeability of alloy and rubber components in the same pump casing, together with a wide range of mechanical seals, make the Tobee heavy duty rubber lined slurry pump the most flexible choice for the chemical plant environment.

Sand & Gravel

Designed for easy and simple strip down and re-assembly, the Tobee heavy duty rubber lined slurry pump minimises downtime, making it the ideal choice where installed stand by pumps are not available.

Sugar Processing

The premium reliability and service life of the Tobee heavy duty rubber lined slurry pump is specified by many sugar plant engineers worldwide where uninterrupted pump operation during the sugar campaign is a critical requirement.

Flue Gas Desulphurisation

The new generation of specially formulated abrasion and corrosion resistant alloys, together with the very latest rubber technology, positions Tobee Pumps firmly as a major supplier of pumps to the FGD industry.

Oil & Gas Exploration

Over a number of years we have developed the proven design of the Tobee heavy duty rubber lined slurry pump ranges to suit the specific demands of offshore applications. We can now offer the most reliable top side solution to erosive wear.

The new generation of specially formulated abrasion and corrosion resistant alloys, together with the very latest rubber technology, positions Tobee Pumps firmly as a major supplier of pumps to the FGD industry.

Oil & Gas Exploration

Over a number of years we have developed the proven design of the Tobee heavy duty rubber lined slurry pump ranges to suit the specific demands of offshore applications. We can now offer the most reliable top side solution to erosive wear.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches