- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Door & Window Frames

-

Brand Name:

-

Nansen

-

product name:

-

Aluminum Profiles

-

Normal Anodizing:

-

7-23micro

-

Normal Power Coating thickness:

-

60-120 micro

-

Length:

-

5.8m

-

Thickness:

-

0.4-20mm or Customized

-

Size:

-

Customized, same as drawings or samples

-

Surface treatment:

-

Mill,anodizing, powder coating, wooden, electrophoresis

-

Certificates:

-

Intertek

-

Standard:

-

GB/T 6892-2015

Quick Details

-

Grade:

-

6000 Series

-

Tolerance:

-

±3%

-

Place of Origin:

-

Shanghai, China

-

Model Number:

-

Door & Window Frames

-

Brand Name:

-

Nansen

-

product name:

-

Aluminum Profiles

-

Normal Anodizing:

-

7-23micro

-

Normal Power Coating thickness:

-

60-120 micro

-

Length:

-

5.8m

-

Thickness:

-

0.4-20mm or Customized

-

Size:

-

Customized, same as drawings or samples

-

Surface treatment:

-

Mill,anodizing, powder coating, wooden, electrophoresis

-

Certificates:

-

Intertek

-

Standard:

-

GB/T 6892-2015

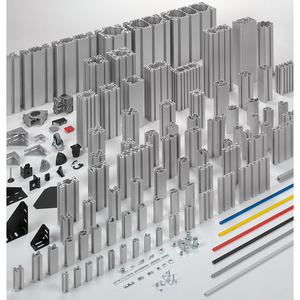

Aluminium Profiles and Accessories nuts Series connectors Pivot Joints Leveling Feet

1-Product Description

|

Material Grade |

Alloy 6000 Series & 7000 Series , 3000 Series |

|

Temper |

T3—T8 |

|

Technology |

Aluminum Extrusion |

|

Surface treatment |

Mill finish, anodizing, powder coated, sandblasting, electrophoresis etc |

|

Color |

Silvery white, black, golden, champagne, dark bronze or according to your requirement |

|

Normal Anodizing thickness |

8-12 micro |

|

Normal Power Coating thickness |

60-100 micro |

|

Shape |

Square, Round, Flat, or according to customers' drawings |

|

Length |

The Standard length of export is 5.8m , |

|

Mill processing |

cutting, drilling, punching, bending milling etc |

|

2D&3D Design |

1: 4 Designers in design and development department 2: Auto CAD, 3D, AI, SLD, PRT. IGS, PDF, JPEG etc. |

|

Engineering& Tooling |

1: Engineers in Mold Shop. 2: Use high tonnage extruder, Wire EDM, CNC, Drilling machines etc. |

|

Quality Control |

INTERTEK Approved. Inspection at Site. Inspection Before Shipping. Testing Machine. |

2-Features of Profiles

· Over 100 different aluminium profiles

· Minimal edge radius (1 mm) for flush connections

· Screw connections for easy reuse

· Anodised surface, no finishing required

· Various end machining options available

3-Chemical Composition (%) Max

4-Surface Treatment :

5-Application

Aluminum profiles are most commonly used across industrial automation applications such as automated motion applications on process lines and industries throughout manufacturing. They are strong and yet light enough that they yet can be easily man-handled and built into various configurations as necessitated by the automation structure. Outside of the traditional automation applications, structural grade aluminum extrusions are even being specified as part of weight reduction efforts. In this sense, they are increasingly being employed as frames in other end use consumer products such as automobiles and LEED building projects. As more advanced aluminum alloys and surface coating techniques are developed, the uses are expanding into these new areas.

Conclusion

In closing, extrusion aluminum sections are versatile and ideal for use in building automation applications, and aluminum is an excellent structural material which lends itself perfectly for use in profile extrusions. More likely than not, there is an aluminum profile that’s perfectly tailored to the specific automation application.

6-Benefits of aluminum CNC machining

· Machinability

· Corrosion resistance

· Strength-to-weight ratio

· Electrical conductivity

· Anodization potential

· Recyclability