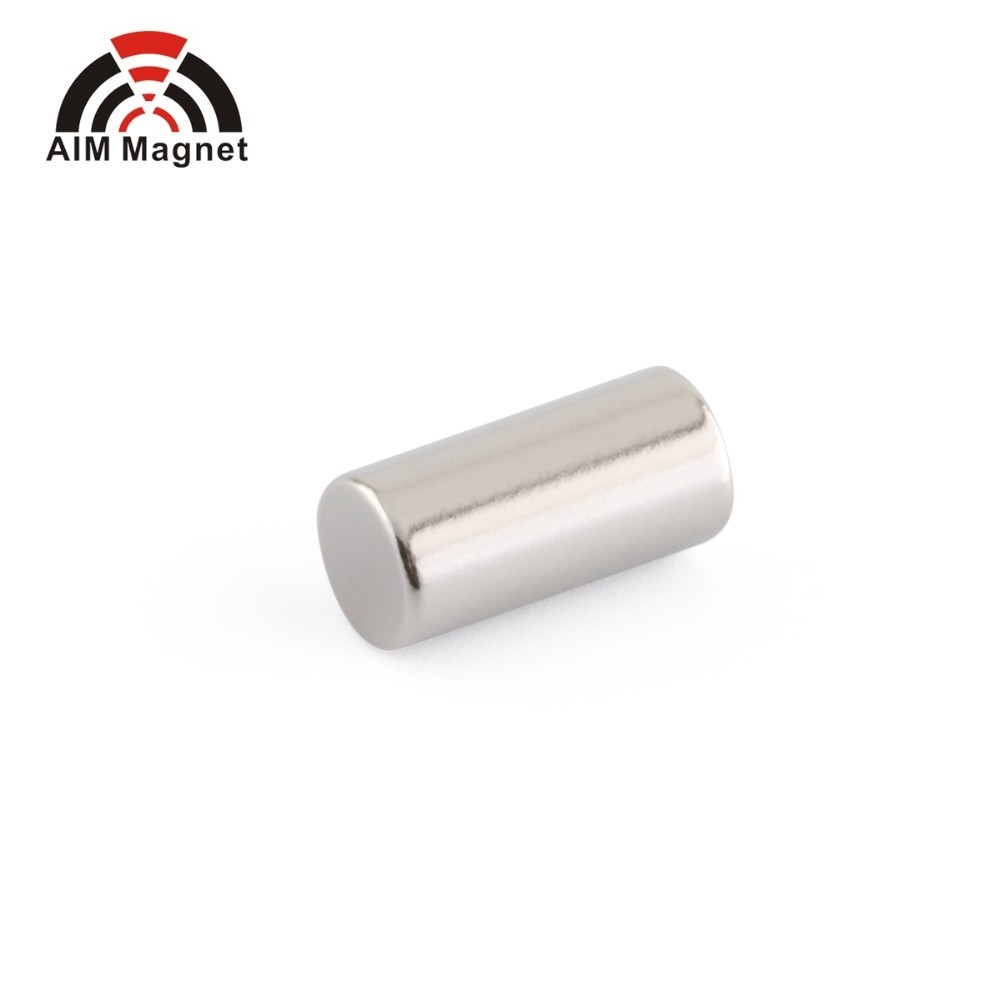

NiCuNi coating stand is 16-22μm(normal is 10-15μm), prevent magnets to be corrosion

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

AIM Magnet

-

Model Number:

-

N35

-

Magnet Name:

-

N35 Round Cylinder Magnet for Channel Sign Letters

-

sample:

-

samples are free if have storage

-

Density:

-

7.45g/mm3

-

Accurate tolerance:

-

±0.05mm ~ ±0.1mm

-

Working Temperature:

-

80℃~230℃

-

Coating:

-

Plastic/Rubber/Epoxy,etc

-

Qualified rate:

-

≥98%

-

Testing:

-

SST: 24~72 hours

-

Delivery:

-

By DHL (3~5days)

-

Certificate:

-

RoHS, Reach, ISO9001:2008

Quick Details

-

Tolerance:

-

±5%

-

Grade:

-

Neodymium magnet

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

AIM Magnet

-

Model Number:

-

N35

-

Magnet Name:

-

N35 Round Cylinder Magnet for Channel Sign Letters

-

sample:

-

samples are free if have storage

-

Density:

-

7.45g/mm3

-

Accurate tolerance:

-

±0.05mm ~ ±0.1mm

-

Working Temperature:

-

80℃~230℃

-

Coating:

-

Plastic/Rubber/Epoxy,etc

-

Qualified rate:

-

≥98%

-

Testing:

-

SST: 24~72 hours

-

Delivery:

-

By DHL (3~5days)

-

Certificate:

-

RoHS, Reach, ISO9001:2008

N35 Round Cylinder Magnet for Channel Sign Letters

1. Factory Price

2. Fast delivery (5~7 days)

3. Most strongest Customized Magnet

4. OEM Accept

5. AIM Magnet Company Found in 2006

|

Neodymium magnet Information

|

|

|

|

Dimensions

|

custom

|

|

|

Tolerances

|

±0.05mm

|

|

|

material

|

NdFeB, Grade N42

|

|

|

Plating/Coating

|

Ni-Cu-Ni (Nickel)

|

|

|

Magnetization

|

Axial (Poles on Flat Ends)

|

|

|

temperature

|

Max is 80ºC

|

|

|

Weight

|

0.66 g

|

|

|

Package

|

custom service accept

|

|

Nicuni Coated

High standard raw material, ensure magnets work stable and durable

Custom Package Accept: 8pcs/set

|

Model 1

|

Model 2

|

Model 3

|

Model 4

|

|

ring magnet

|

countersunk magnet

|

adhesive magnet

|

Pvc Coated magnet

|

|

Surface

|

Coating

|

Thickness (Microns)

|

Color

|

Resistance

|

|

Passivation

|

|

0-1

|

Silver Grey

|

Temporary Protection

|

|

Nickel

|

Ni+Ni

|

10-20

|

Bright Silver

|

Excellent against Humidity

|

|

|

Ni+Cu+Ni

|

|

|

|

|

Zinc

|

Zn

|

8-20

|

Bright Blue

|

Good Against Salt Spray

|

|

|

C-Zn

|

|

Shinny Color

|

Excellent Against Salt Spray

|

|

Tin

|

Ni+Cu+Sn

|

15-20

|

Silver

|

Superior Against Humidity

|

|

Gold

|

Ni+Cu+Au

|

10-20

|

Gold

|

Superior Against Humidity

|

|

Copper

|

Ni+Cu

|

10-20

|

Gold

|

Temporary Protection

|

|

Epoxy

|

Epoxy

|

15-25

|

Black, Red, Grey

|

Excellent Against Humidity & Salt Spray

|

|

|

Ni+Cu+Epoxy

|

|

|

|

|

|

Zn+Epoxy

|

|

|

|

Q1. Why are chosen us?

A:

-We are a professional magnet manufacturer since 2006. Our plating factory is the benchmark in the Shenzhen NdFeB industry.

- No returned goods for five years in Europe market.

- We provide magnets for a dozen of Fortune Global 500 enterprises such as Apple, Samsung, Lenovo etc.

- In Europe market, 80% permanent magnets used for range hood are from AIM Magnet Co., Ltd.

- Our company is the main supplier of American top wine box.

- With rich exporting experiences with neodymium magnets, we build supply chain to offer neodymium magnets with professional service.

Q2. What about the lead time?

A:Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than

Q3. How to control the magnetic property?

A: Hight stander raw material

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional.

Q5. How to control the tolerance?

A:

- 1. before ginding and cuting, we inspection the black product tolerance.

- 2. before and after coating, we will inspection the tolerance by AQL standard

- 3. before delivery, will inspection the tolerance by AQL standard

Q6. Is it OK to print my logo on magnet product pr package?

A: Yes. Please inform us formally before our production and confirm the design firstly based on our sample.

Q7: How to control coating ?

A:

- 1. we have a coatIng factory

- 2. after coating, first inspection by visual, and second is salt spray test, nickel 48-72 hours, zinc 24-48 hours

Q8: How to control the packing?

-1. standard packing,

- 2. the cartons must can be bear a man's weight.

- 3. the cartons must be well after fall down test from 1m high position. and the inner packing must not change position