- Product Details

- {{item.text}}

Quick Details

-

Working stroke:

-

500/300/300/100mm

-

Plasma power:

-

600W/25KHZ

-

Processing height:

-

5~20mm

-

Processing width:

-

0~1600mm

-

Moving speed:

-

300~800mm/s

-

Repeatability:

-

±0.02mm

-

Display mode:

-

LED teaching box

-

Working gas:

-

0.2~0.4Mpa

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XHL

-

Product model:

-

XHL-331 single station glue dipensering machine

-

Working stroke:

-

500/300/300/100mm

-

Plasma power:

-

600W/25KHZ

-

Processing height:

-

5~20mm

-

Processing width:

-

0~1600mm

-

Moving speed:

-

300~800mm/s

-

Repeatability:

-

±0.02mm

-

Display mode:

-

LED teaching box

-

Working gas:

-

0.2~0.4Mpa

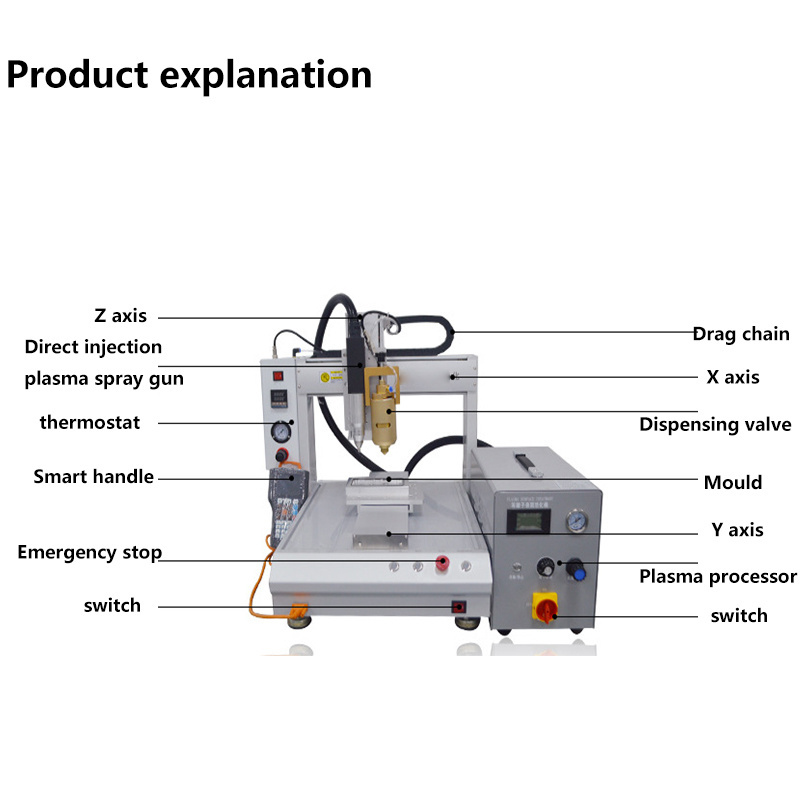

Customized Plasma Surface Treatment Dispensing Integrated Machine Low Temperature Atmospheric Pressure Surface Gluing Machine

Product Description

Specification

Feature

1. The jetted plasma stream is neutral and non-charged, and can be used for surface treatment of various polymers, metals, glass, rubber, PCB circuit boards and other materials;

2. Improve the bonding strength of plastic parts. For example, PP material can be increased several times after treatment. After most plastic parts are treated, the surface energy can reach 60 dynes or more;

3. After plasma treatment, the surface performance is lasting and stable, and the retention time is long;

4. The dry method has no sewage, no pollution, and meets environmental protection requirements;

5. It can be processed online on the production line to reduce costs;

6. After the plasma surface processor is processed, ordinary glue can be used to glue the box to reduce the cost

Packing & Delivery

Hot Searches