- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Name:

-

Molten iron pouring ladle for casting foundry

-

Color:

-

Customer Requirement

Quick Details

-

Place of Origin:

-

China

-

Machine Type:

-

Molten iron pouring ladle

-

Marketing Type:

-

New Product

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Name:

-

Molten iron pouring ladle for casting foundry

-

Color:

-

Customer Requirement

Excellent quality stainless steel pouring ladle

Description

Excellent quality stainless steel pouring ladle

Stainless steel pouring ladle used for pouring operations, after receiving the liquid metal in the blast furnace, transported by road to the mold at the pouring. Into ladle, ladle, teapot package, ductile iron package and other styles. Ladle boom, forging rings belong together, better than ordinary steel cutting strength, safe and reliable. Meanwhile packet size, the material produced by the national machinery industry standards (standard JB5550-91, JB / T5771-91). Kowtow and card gear phenomenon does not exist there. Gearbox with double worm gear transmission, although the manufacturing requirements, but flexible and comfortable drive, a good two-way reversible.

Feature

1).Reasonable choose the rotation center, convenient operation, basic can compound when pouring is finished .

2).Adopt double worm wheel pair transmission.Although manufacturing demand is high, but flexible transmission, two-way reversible .

3).Enclosure is made of thicker steel plate, the bottom of the bag structure by adopting the combination of taper, bottom rim, welding triple insurance, which extended the service life, and ensure the safety of the operator .

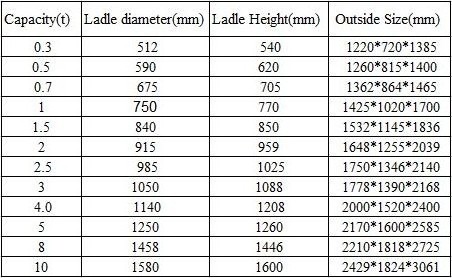

Technical parameter

Product shows

Packing and Shipping

Our clients

Company shows

Our services

1.Reply your inquiry in time.

2. Experienced staffs answer all your questions in time.

3. Customized design is available.

4. Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

5. Special discount and protection of sales are provided to our distributor.

6. Professional factory: We are manufacturer, specializing in producing all kinds of Shot Blasting Machine & Molding Machine & Core Shooting Machine for more

than 40 years, competitive with good quality.

7. As an honest seller, we always use superior raw material, advanced machines, skilled technicians to ensure our products to be finished in high quality and stable feature.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 10-30 days if the goods are not in stock, it is according to clients' requirements.

Q: Do you have warranty period ?

A: Yes, we could offer 0.5-1 year warranty period.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Looking forward to your detailed information

If you are interested in this equipment, please don't hesitate to contact us!

If the machine is not suitable for your workpiece, please tell us the following infromation:

1) What kind of workpiece will you clean?

2) The size of workpieces(length, width and height of maximum workpiece,Length, width and height of minimum workpiece?)

3) How many the weight of maximum and minimum workpiece?

4) Please tell us your requirement cleaning efficiency?

According to your infomation, the most suitable machines will be designed for your workpieces.

Related products

Please click on the picture !

Contact us