- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Current:

-

14.4A

-

Dimensions:

-

47X 36 X 51cm

-

power:

-

10kw

-

feature:

-

portable, handheld

-

size:

-

small size

-

applications:

-

metal heat treatment

-

Color:

-

black&white

-

certifications:

-

CE ISO etc

-

warranty:

-

1 year

-

product name:

-

water cooling power source induction heating system

-

inductors:

-

can be customized

-

Frequency:

-

10-40KHZ

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Canroon

-

Weight (KG):

-

60

-

Voltage:

-

380V

-

Current:

-

14.4A

-

Dimensions:

-

47X 36 X 51cm

-

power:

-

10kw

-

feature:

-

portable, handheld

-

size:

-

small size

-

applications:

-

metal heat treatment

-

Color:

-

black&white

-

certifications:

-

CE ISO etc

-

warranty:

-

1 year

-

product name:

-

water cooling power source induction heating system

-

inductors:

-

can be customized

-

Frequency:

-

10-40KHZ

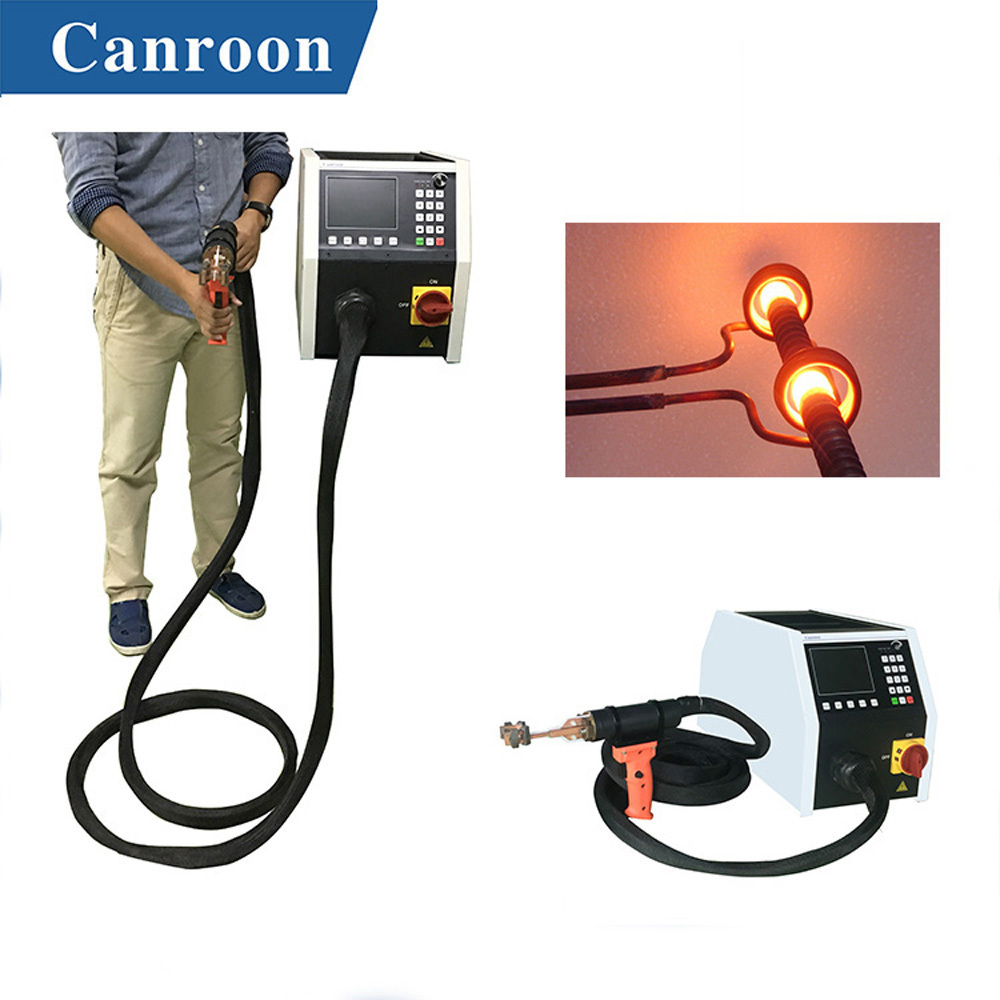

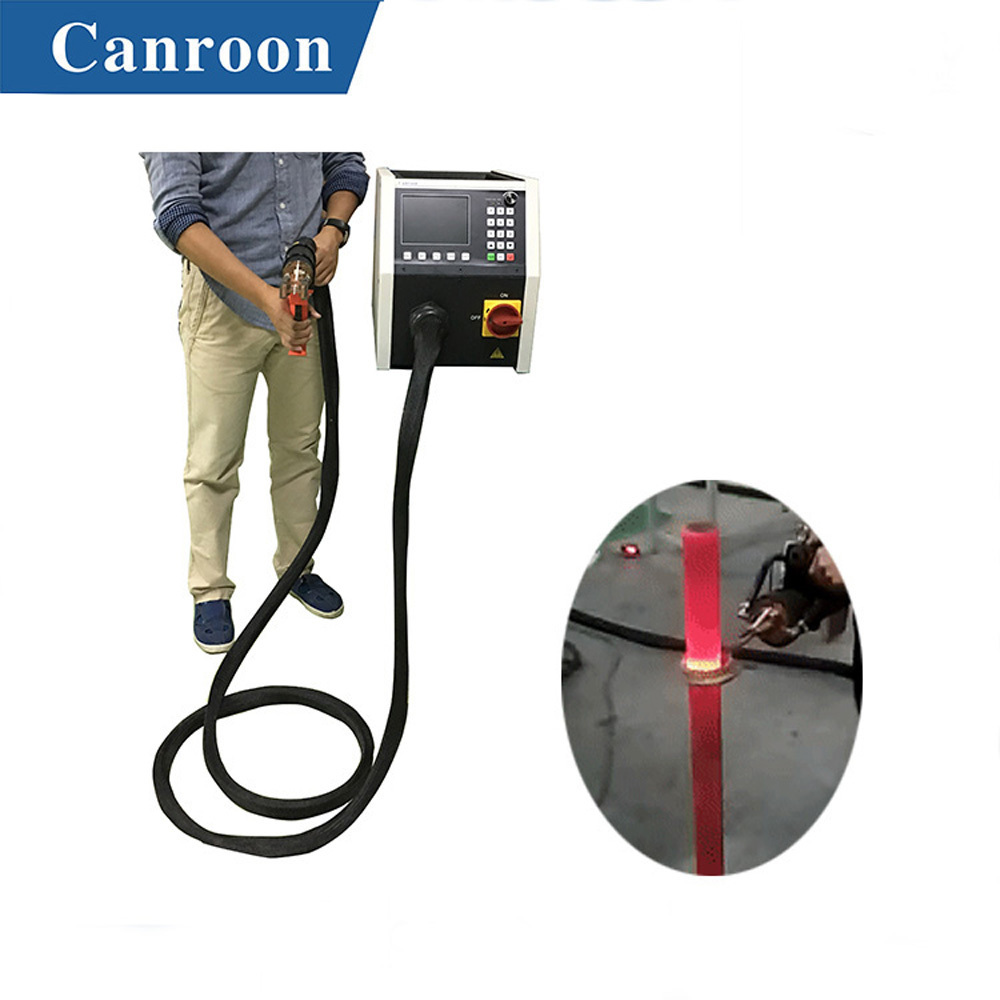

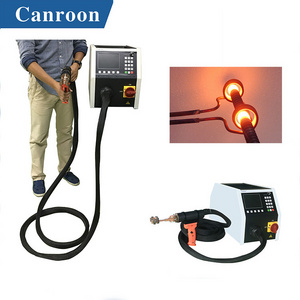

10KW to 60KW water cooling power source induction heating system for brazing

Canroon portable induction heating power supply CR2100 series adopts DSP digital control system and The coaxial transformer with small size and light weight is specially designed for supporting industrial robots and automation equipment And a highly integrated power supply for manual hand-held heating, It is widely used in brazing/welding, curing, Thermal expansion,hardening/quenching, straightening, etc.

Adopt DSP full digital control system:

1. Accurate control in constant current mode,current fluctuation does not exceed 0.5 A, high repeat accuracy, basically no deviation.

2. It can realize continuous segmented heating and can be applied to various complex environments.

3. Color screen display, convenient and easy to operate, can be used after simple training.

4. Complete protection functions, under voltage, water shortage, over current, overheat protection of the core components of the equipment.

5. Rich interface forms to facilitate communication with PLC and computer.

6. Program control, easy to achieve system upgrade.

Parameters of Canroon portable induction heater/induction heating machine for metal heat treatment:

|

Model |

Rated input voltage & frequency |

Rated input power |

Rated input current |

Output frequency |

Cooling water pressure / flow rate |

Dimension |

|

CR2100-010B-14TW1 |

3-phase

|

10KVA |

15A |

10~40KHZ |

4~6 bar ≥12L/min |

L: 581.5mm W: 283mm H: 334mm |

|

CR2100-015B-14TW1 |

15KVA |

22A |

||||

|

CR2100-020B-14TW1 |

20KVA |

30A |

||||

|

CR2100-025B-14TW1 |

25KVA |

37A |

4~6 bar ≥19L/min |

|||

|

CR2100-030B-14TW1 |

30KVA |

45A |

||||

|

CR2100-035B-14TW1 |

35KVA |

53A |

||||

|

CR2100-040B-14TW1 |

40KVA |

60A |

||||

|

CR2100-050B-14TW1 |

50KVA |

75A |

Picture of Canroon 10kw portable handheld induction heater/induction heating machine for metal heat treatment:

Advantages:

· High Temp. & Fast Heating

Able to reach >1000 ℃ within seconds.

· Easy Operation

CR2100 can be easily start&stop manually, and scan on workpieces surface to do local heating. It can also be integrated into robot arm to serve automatic line.

· Accurate Control

The interface offers two basic control modes to choose including temperature control and power control . The former one has 4 modes of Constant Temp . , bake-out , HT (heat treatment) , custom . The last one has 2 modes of constant power and power VS time . Each mode offers different parameters to set. Thus brings the benefit of wide applicability and precise control of heating process.

· Fault Record

Fault codes will display and be recorded for reference, and system will respond with protection action like shutdown once fault occurs such as open-loop output or short out.

· Easy Maintenance

Due to modular design, the maintenance will be easy and low-cost.

· Self-Diagnosis

Once fault occurs, CR2000 will act with display of fault code, which was detailed explained in the manual book.

· Customized Inductor

Canroon provided high-standard customized inductor to CR2100 induction generator, to help you deal with workpieces of different shap&size.

Application Ranges for induction welding machine:

1. metal tube welding: such as copper tube, steel tube, and aluminum tube’s butt welding, plug welding and welding sets.

2. alloy cutter welding: such as alloy turning tool, milling cutter, planer, saw blades, reamer, boring knife.

3. carbide saw blade welding: diamond saw blade welding, marble saw blade welding, woodworking saw blade welding,cut grass piece of welding, cut aluminum welding.

4. metal welding: such as: towel rack, soap nets, towel holder, auto-accessories, motor accessories, metal terminals, hardware pieces, electric heating tube parts and fasteners.

5. customized service: make machine according to customers' actual working situation.

Some of applications of 10kw portable handheld induction heater/induction heating machine for metal heat treatment:

HHT(hand held transformer) is easy to operate, and can be integrated with Robot Arm for automotion production, two buttons to control the machine working:

Inductors are important part of induction heater, so it is precisely designed, manufactured by good quality material, and tested many times before outgoing, it is detachable, and can be customized accoridng to your needs:

All of our equipment is packed in wooden case or carton box, delivery by sea, Express or by air.