- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

11700x7710x12200mm

-

Weight:

-

46000 KG

-

Feeding Size:

-

<38 to 55 mm

-

Application:

-

Stone Powder Grinding

-

Grinding way:

-

Roller Grinding

-

Feature:

-

Fine Discharge

-

The Machines classification:

-

Granding Mill Machine

-

Spare parts supplying:

-

Anytime

-

After sale service:

-

Life-long Service

-

Test&Installation:

-

Professional Engineer Assigned

-

Quality:

-

High Level

Quick Details

-

Capacity(t/h):

-

7-200 t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LIMING

-

Dimension(L*W*H):

-

11700x7710x12200mm

-

Weight:

-

46000 KG

-

Feeding Size:

-

<38 to 55 mm

-

Application:

-

Stone Powder Grinding

-

Grinding way:

-

Roller Grinding

-

Feature:

-

Fine Discharge

-

The Machines classification:

-

Granding Mill Machine

-

Spare parts supplying:

-

Anytime

-

After sale service:

-

Life-long Service

-

Test&Installation:

-

Professional Engineer Assigned

-

Quality:

-

High Level

Coal grinding machine/coal grinding mill/coal pulverizer/grinder/micronizer

| Production Description | Contact Us |

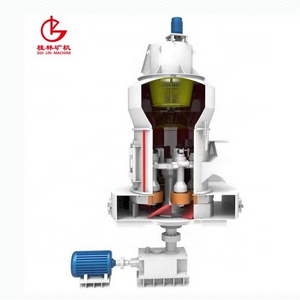

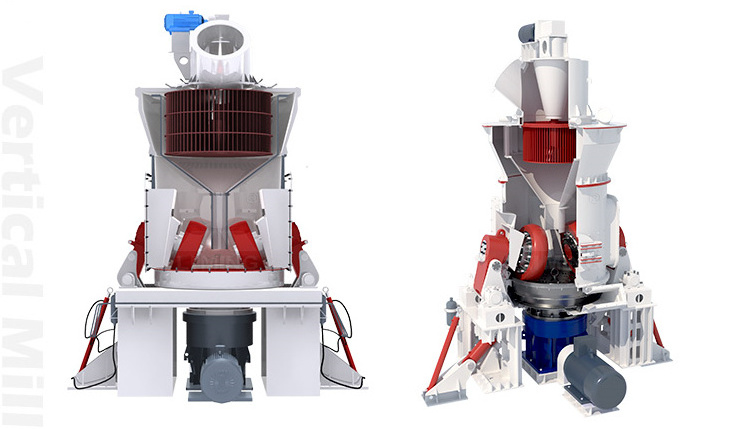

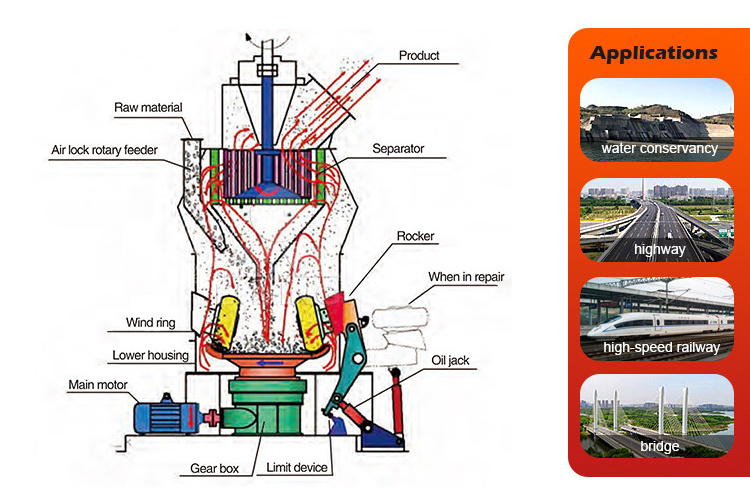

Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing non-metallic minerals, pulverized coal and slag. Its coverage area is reduced by 50% compared with ball mill, and the energy consumption is saved by 30%-40% similarly.

Applications of Coal grinding machine/coal grinding mill/coal pulverizer/grinder/micronizer :

Cement, coal, power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

| Working Principle | Contact Us |

Vertical mill has two pairs of grinding rollers, each pair of roller composed of two narrow rollers, mounted on the same axis and can rotate at different speeds. There are two circular disc slot, and roller to the tire shape, work pressure in the tank. Disc roller and the relative sliding velocity between small and roller can swing, even if the roller sleeve and the disc after the liner wear can guarantee a good abrasive, will not affect the grinding effect. Roller symmetrical structure, one side can be upside down after use and wear. Material grinding process: hydraulic pneumatic roller device through the pressure applied to the material on the crushing of materials, the materials have been moved to crush the edge of disc, from the disc around the nozzle from the exhaust air to improve these materials to Separator.Meal to separate returns after a concentrated mill, fine powder was collected in the precipitator unloading. In the gas flow is small, the meal can not be increased to enhance air flow, they would fall through the nozzle discharged outside the mill, bucket elevator to be transported to the feeder of vertical mill and was re-grinding mill feed people.

This cycle features of the way there:

ring by adjusting the air valve, can change the product fineness can shide mill bed load material uniformity and stability, improving the grinding efficiency;

coarse particles in the external circulation, helps reduce Fan power consumption and overall system power.

Configuration of Coal grinding machine/coal grinding mill/coal pulverizer/grinder/micronizer :

1. Crusher to break large stones into smaller size;

2. Suitable particles to be transferred to vertical mill;

3. Finished products after being ground in the Raymond mill and separated by the classifier. Dust removing system should be equipped to avoid pollution;

4. Storage of finished products for packaging;

| Features | Contact Us |

1. Low Investment Cost

This mill itself can crush, dry, grinding, classifying, so the system is simple, and occupation area is about 50% of ball mill system. In addition, it can be installed outside, so it will reduce a large number of investment costs.

2. Low Operation Cost

High efficiency: roller compacted materials directly onto the grinding disc, so power consumption is low. Compared with ball mill, it saves energy consumption by 30% ~ 40%.

3. High Drying Ability

As the hot air inside contacts directly with the material, drying ability is higher, and it saves energy. By regulating the air temperature, it can meet requirements with different humidity.

4. Simple and reliable operation

It is equipped with automatic control systems, so remote control makes it easy to operate.

5. The stability of product quality

As the material stays in the mill for a short time, it is easy to detect and control the product particle size and chemical composition, to reduce duplication of milling, stable product quality.

6. Maintenance convenience

By repairing fuel tank, rotating the arm, it is fast to replace the roller sleeve, and liner, and reduce the downtime loss.

7. Environmental protection

It is with small vibration, low noise, and the overall sealing. The system works under negative pressure, so there is no dust going out.

Vietnam 12TPH Coal Grinding Plant

Material: Coal

Capacity: 12TPH

Daily Operation: 24h

Input Size: <35mm

Output Size: R0.08=10%-12%

Application: Used in steel plant

Equipment: LM130M Vertical milling system

| Technical Parameters | Contact Us |

| Models and parameters | Vertical Mineral Mill Series | ||||||

| LM130K | LM150K | LM170K | LM190K | LM220K | LM280K | ||

| Plate diameter (mm) | 1300 | 1500 | 1700 | 1900 | 2200 | 2800 | |

| Capacity (t/h) | 10-28 | 13-38 | 18-48 | 23-68 | 36-105 | 50-170 | |

| Output fineness | μm | 170-40 | 170-40 | 170-40 | 170-40 | 170-45 | 170-45 |

| Mesh | 80-400 | 80-400 | 80-400 | 80-400 | 80-325 | 80-325 | |

| Max feed size(mm) | <38 | <40 | <42 | <45 | <50 | <50 | |

| Main motor (kW) | 200 | 280 | 400 | 500 | 800 | 1250 | |

| About Us | Contact Us |

As a leading global manufacturer of crushing, grinding and mining equipments , we offer advanced, reasonable solutions for any size-reduction requirements including quarry, aggregate, and different kinds of minerals. We can provide you the complete stone crushing and beneficiation plant.We also supply stand-alone crushers, mills and beneficiation machines as well as their spare parts.

Our products have been sold to 100 countries and areas of Southeast Asia, East Europe, South America, the Middle East and Africa etc, and more foreign markets will be promoted in future.

* All our products are CE, ISO and GOST certified

* All of our products are made with care and covered for 1 year warranty!

| Our Service | Contact Us |

Pre-sales Service

*Help customers to choose product.

*Freely send engineers to the working field to plan the installation site and design the best technical production process.

*Design the special product according to the contract.

After-sales Service

*Send the engineers to guide the installation.

*Install and adjust the equipment for customers.

*Train the operator for customers.

*We also provide the technical service for our customers after the installation.

| Packaging & Shipping | Contact Us |

The machine is nude packing , motor and other accessories are packing in wooden box.