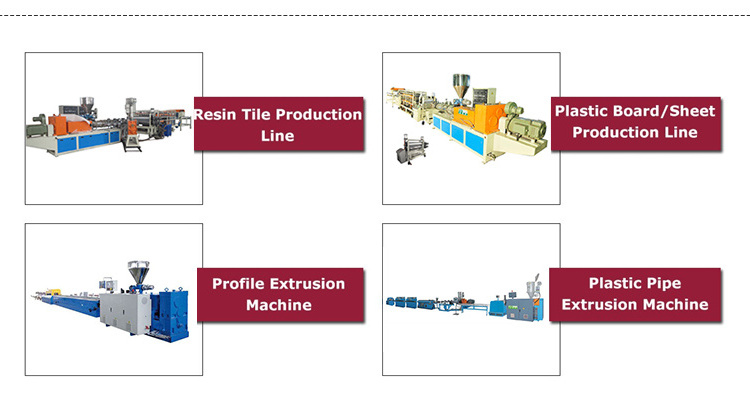

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

1500 rpm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

POLYTECH

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

20mx2.5mx2.2m

-

Power (kW):

-

55

-

Weight:

-

20000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Plastic Pipe Extrusion Line

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

156:1

-

Screw diameter (mm):

-

75 mm

-

Screw Speed (rpm):

-

1500 rpm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

POLYTECH

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

20mx2.5mx2.2m

-

Power (kW):

-

55

-

Weight:

-

20000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Plastic Pipe Extrusion Line

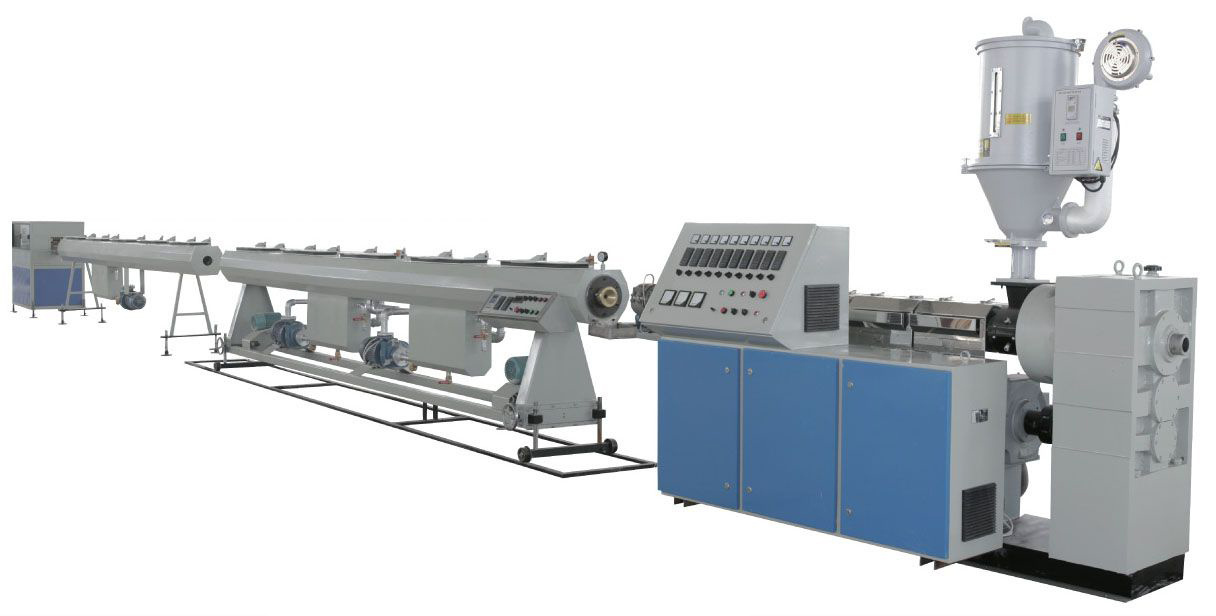

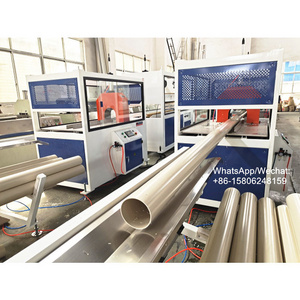

Saving -Energy UPVC/CPVC/PVC Plastic Pipe Production Extrusion Line machine

Production Description :

Saving -Energy UPVC/CPVC/PVC Plastic Pipe Production Extrusion Line /Pipe Making Machine adopts friendly interfa

-ce, intelligent control, it is convenient for use and reliable in working. The screw,gear-reducer and mould are specially

-designed for high temperature,high viscosity,difficult plasticization of the PVC/CPVC melt and ensure the continuous p

-roduction with stability. The finished product widely used in drainage, electricity cable transportation etc. It can extrude

the single wall pipe, foamed core pipe, inner spiral pipe with one, or more cavities pipe extrusion.

Specifications:

|

|

Screw diameter(mm)

|

Main motor power (kw)

|

Max output(kg/h)

|

Calibrating length(mm)

|

Mode of haul-off |

Cutting mould |

Pipe diameter(mm)

|

|

SJG-110/50 |

51/105 |

22 |

~180 |

4000 |

two rubber belt

|

saw cutting

|

Φ50-110 |

|

SJG-200/160 |

65/132 |

37 |

~250 |

4000 |

three rubber belt

|

saw cutting

|

Φ160-200 |

|

SJG-400/250 |

80/156 |

55 |

~380 |

6000 |

four rubber belt |

planet cutting

|

Φ250-400 |

|

SJG-630/400 |

92/188 |

90 |

~600 |

6000 |

six rubber belt |

planet cutting

|

Φ400-630 |

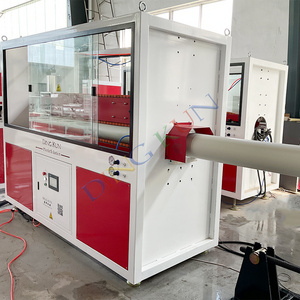

Applications:

Saving -Energy UPVC/CPVC/PVC Plastic Pipe Production Extrusion Line /Pipe Making Machine adopts friendly interf

-ace, intelligent control, it is convenient for use and reliable in working. The screw,gear-reducer and mould are specially

designed for high temperature,high viscosity,difficult plasticization of the PVC/CPVC melt and ensure the continuous pro

-duction with stability. The finished product widely used in drainage, electricity cable transportation etc. It can extrude th

-e single wall pipe, foamed core pipe, inner spiral pipe with one, or more cavities pipe extrusion.

which is high-intensity,high temperature-resistant,chemical-resistant,insulate and flame retardant. The pipe is the best c

-hoice for protect power cable and have good prospects.

Advantage of the UPVC/CPVC pipes:

1.Non-toxic: no heavy metal additives, not be covered with dirt, not be contaminated by bacterium.

2.Corrosion Resistant: resist chemical matters or electron chemical corrosion.

3.Lower Installation Costs: light weight and ease of installation can reduce installation costs by as much as 50% over

metal piping system.

4.Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes.

5.Long Life: more than 50 years under normal conditions.

6.Recycled and Environment-friendly.