- Product Details

- {{item.text}}

Quick Details

-

Core:

-

Poplar Hardwood Combi pine

-

Face/back:

-

Melamine paper coated both side

-

Thickness:

-

6mm-30mm

-

Size:

-

1220*2440/1250*2500/610*2440/1220*1220

-

Application:

-

Furniture Decoration

-

Glue:

-

MR/E0/E1/E2/WBP/Melamine

-

Certification:

-

CE ISO9001 FSC CARB

-

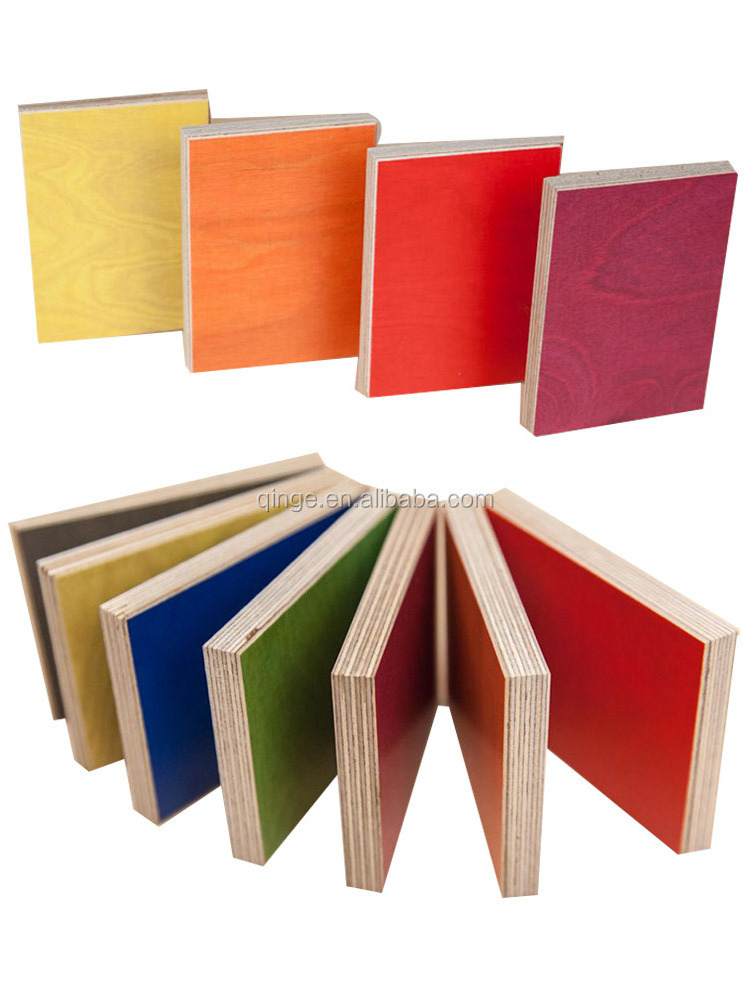

surface color:

-

wood grain, bright,ultra bright, matte

-

MOQ:

-

1x20ft

Quick Details

-

Formaldehyde Emission Standards:

-

E0

-

Place of Origin:

-

Anhui, China

-

Product name:

-

Melamine Laminated Plywood

-

Core:

-

Poplar Hardwood Combi pine

-

Face/back:

-

Melamine paper coated both side

-

Thickness:

-

6mm-30mm

-

Size:

-

1220*2440/1250*2500/610*2440/1220*1220

-

Application:

-

Furniture Decoration

-

Glue:

-

MR/E0/E1/E2/WBP/Melamine

-

Certification:

-

CE ISO9001 FSC CARB

-

surface color:

-

wood grain, bright,ultra bright, matte

-

MOQ:

-

1x20ft

|

Size |

1.Small sizes:915x2135mm,1200x1800mm,1525x1525mm 2.Standard sizes:1200X2400mm,1220x2440mm,1250x2500mm 3.Big size:1500x3000mm |

|

Thickness |

3,6,9,12,15,16,17,18,19,20,21,25,27,30mm |

|

F&B |

brown film,Black film,red film,green film and so on |

|

Finish |

Smooth,mesh(anti-slip),with or without logo( customized logo by customers ) |

|

Core |

Poplar,Hardwood,Eucalyptus,Birch,Pine,Combi and etc |

|

Glue |

WBP(PHENOLIC-boiled for 48hours,reused times 15-20/MELAMINE-boiled for 6-8hours,reused times 8-12/MR-boiled for one hour,reused times 6-8)Amount of the glue,take 1.7mm thickness veneer for example,the amount of glue used in other factory is 0.25kg/m2, and our use is 0.33kg/m2,it will ensure the high strength of plywood in application. |

|

Formaldehyde release |

E1≤1.5mg/L E2≤5.0mg/L |

|

Hot press |

one time hot pressed,two time hot pressed,(difference: two time hot pressed plywood smooth surface;one time hot press,low cost and cheap price.Choose by your market) |

|

Cycle life |

6-20 times |

|

Tolerance |

+/-0.5mm,+/-0.8mm |

|

Grade |

A,AA,AAA |

|

MOR/MOE |

MOR ≥30Mpa;MOE ≥6000Mpa |

|

Moisture |

Less than 12% |

|

Density |

poplar:530~500kgs/cbm,hardwood:600~580kgs/cbm |

|

Edges |

Four edges will be sealed with water-proof paint(red, green or others) |

|

Usage |

Ideal concrete construction materials |

|

Packing |

Inner packing:0.2mm thickness plastic bag Outer packing:pallet with carton and strpped with steel tape |

|

Delivery |

Within 20days after confirm the order |

|

Load Qty |

1>In container:20GP--8Pallets,40GP--16Pallets,40HC--18Pallets 2>In bulk ship:35sheets/pallet |

|

Payment |

T/T or L/C |

Feature:

1. If put in boiling water for 48 hours, it is still glue-sticking and non-deformed

2. Physical mood is better than iron moulds and can satisfy the requirements of constructing mould, while the iron ones are easy to be deformed and can hardly recover its smoothness even after repairing

3. If used abide by the illustrations strictly, it can be reused more than 30 times, so reducing the cost greatly and avoiding the disadvantages from ( rustily and erosive of iron mould)

4. Solves the problems of leaking and rough surface during constructing process

5. Particularly suitable for watering concrete project because it can make the concrete surface smooth and flat

6.Realizing a higher economic profits