- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Fengwei

-

Dimension(L*W*H):

-

2.3*2.3*3.0

-

Weight (KG):

-

4350 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Bin Washing Machine

-

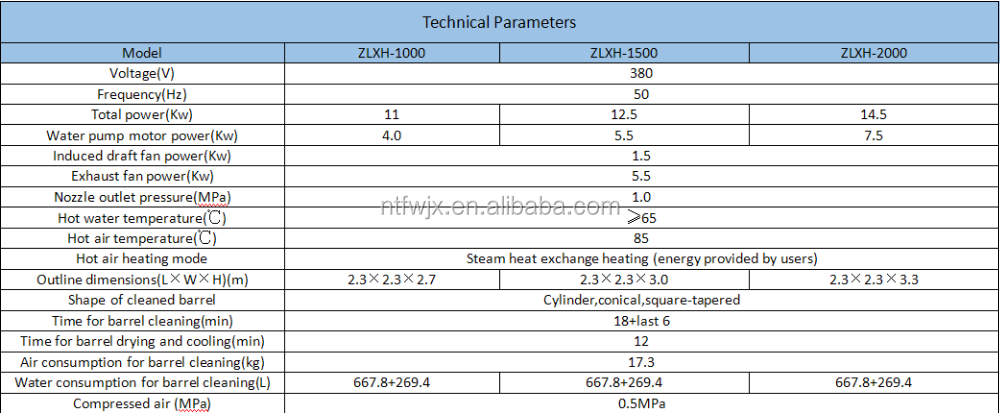

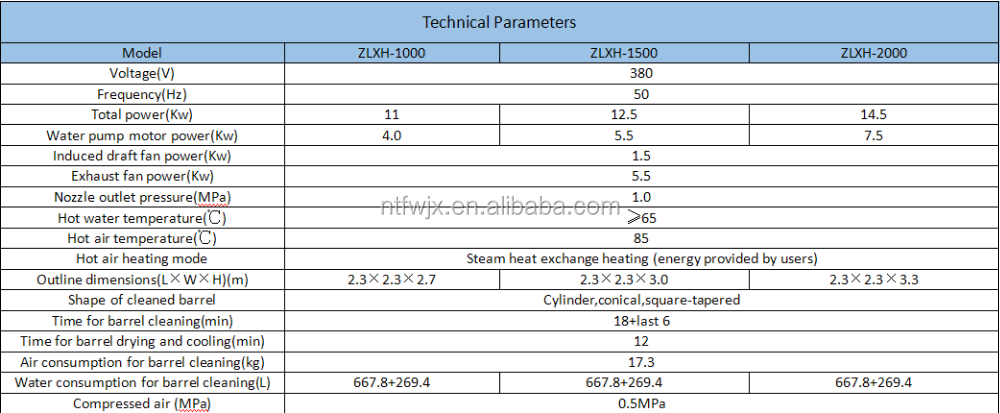

Model:

-

ZLXH-1500

-

Function:

-

Clean the bin

-

Power Supply:

-

380V/50Hz

-

Certification:

-

ISO CE

-

Total power:

-

12.5kw

-

Outline dimensions:

-

2.3*2.3*3.0

-

Compressed air:

-

0.5MPa

Quick Details

-

Cleaning Process:

-

Cold Water Cleaning

-

Power:

-

5.5Kw

-

Max. Pressure:

-

Other

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Fengwei

-

Dimension(L*W*H):

-

2.3*2.3*3.0

-

Weight (KG):

-

4350 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Bin Washing Machine

-

Model:

-

ZLXH-1500

-

Function:

-

Clean the bin

-

Power Supply:

-

380V/50Hz

-

Certification:

-

ISO CE

-

Total power:

-

12.5kw

-

Outline dimensions:

-

2.3*2.3*3.0

-

Compressed air:

-

0.5MPa

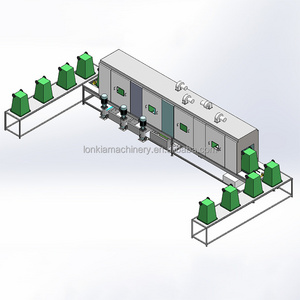

PURPOSE:

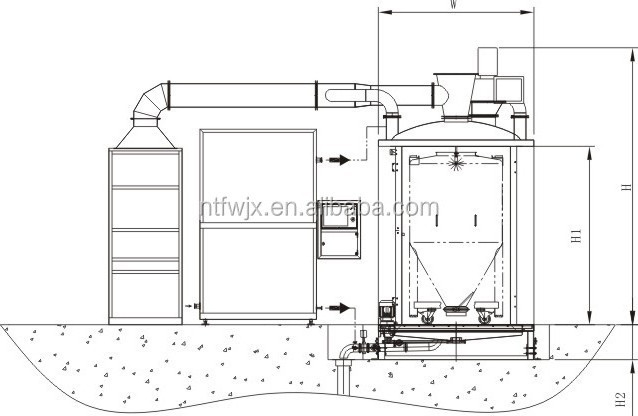

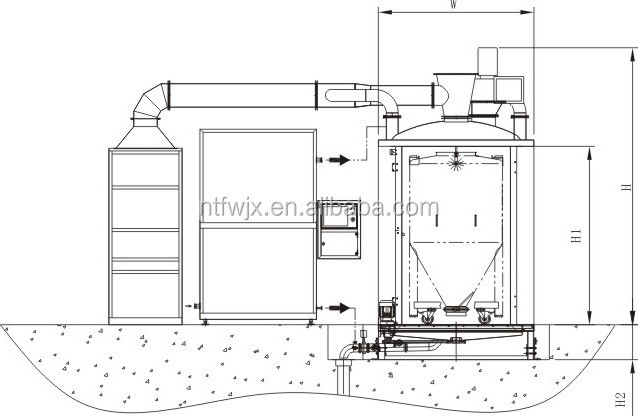

The ZLXH automatic barrel cleaning dryer is independently researched and developed by our company. With reasonable design, compact structure, stable running and simple operation, the machine is an ideal barrel cleaning machine for optimizing production processes in pharmaceutical enterprises.

PRINCIPLE:

When it works, put the barrel to be cleaned on the machine. Press the operation button and the machine will be able to use detergent, warm water and pure water to automatically carry out cleaning and drying of the hopper according to the set time through the nozzles.

design, compact structure, stable running and simple operation, the machine is an ideal barrel cleaning machine for optimizing production processes in pharmaceutical enterprises.

FEATURE:

1. The structural components are all elaborately made of 304 stainless steel with beautiful appearance.

2. The fluid and gas control parts and nozzles are imported products with original packaging. The electrical control adopts programmed control.

3. Integrating the functions of cleaning and drying the barrel, the machine is easy to operate.

4. The barrel can be cleaned thoroughly without residual impurities after cleaning, avoiding the defect of residual impurities caused due to negligence during manual cleaning.

5. The machine cleans the barrel rapidly and efficiently, saving large amounts of time and manpower.