- Product Details

- {{item.text}}

Quick Details

-

name:

-

Tungsten Carbide Stone Cutting Tips Manufacturer

-

material:

-

tungsten carbide

-

certification:

-

ISO9001:2008

-

Grade:

-

K10/K20/K30 /YG6/YG8X/YG15

-

size:

-

can be customized

-

application:

-

cutting wood, metal, stone

-

Feature:

-

hardness 86-93

-

Color:

-

Grey

-

Advantage:

-

Good Wearbility, 20 years experience

-

Keywords:

-

carbide inserts manufacturers carbide chainsaw insert

Quick Details

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Rixin

-

Model Number:

-

virous

-

name:

-

Tungsten Carbide Stone Cutting Tips Manufacturer

-

material:

-

tungsten carbide

-

certification:

-

ISO9001:2008

-

Grade:

-

K10/K20/K30 /YG6/YG8X/YG15

-

size:

-

can be customized

-

application:

-

cutting wood, metal, stone

-

Feature:

-

hardness 86-93

-

Color:

-

Grey

-

Advantage:

-

Good Wearbility, 20 years experience

-

Keywords:

-

carbide inserts manufacturers carbide chainsaw insert

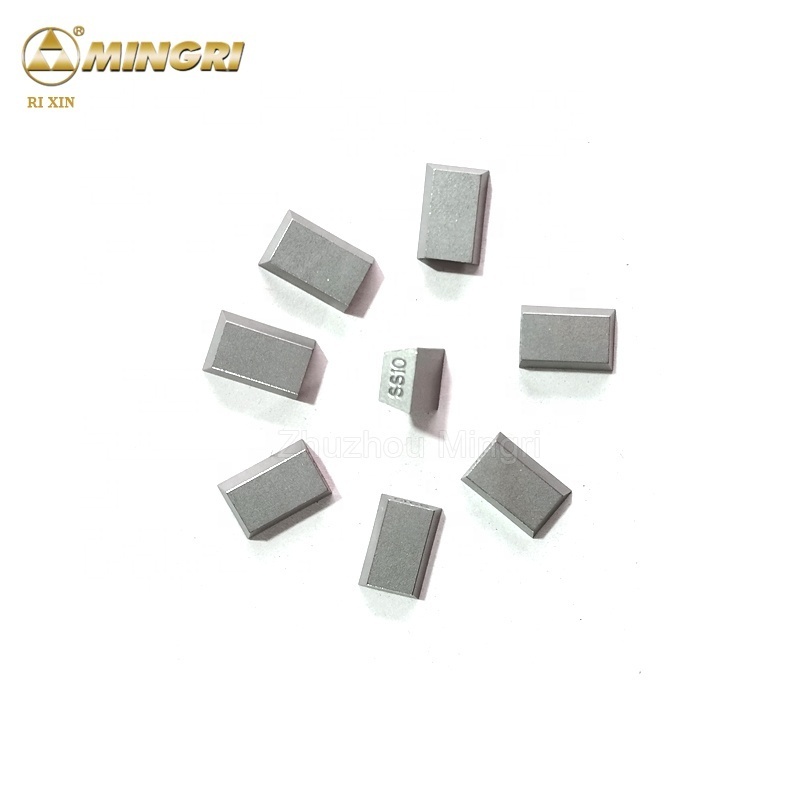

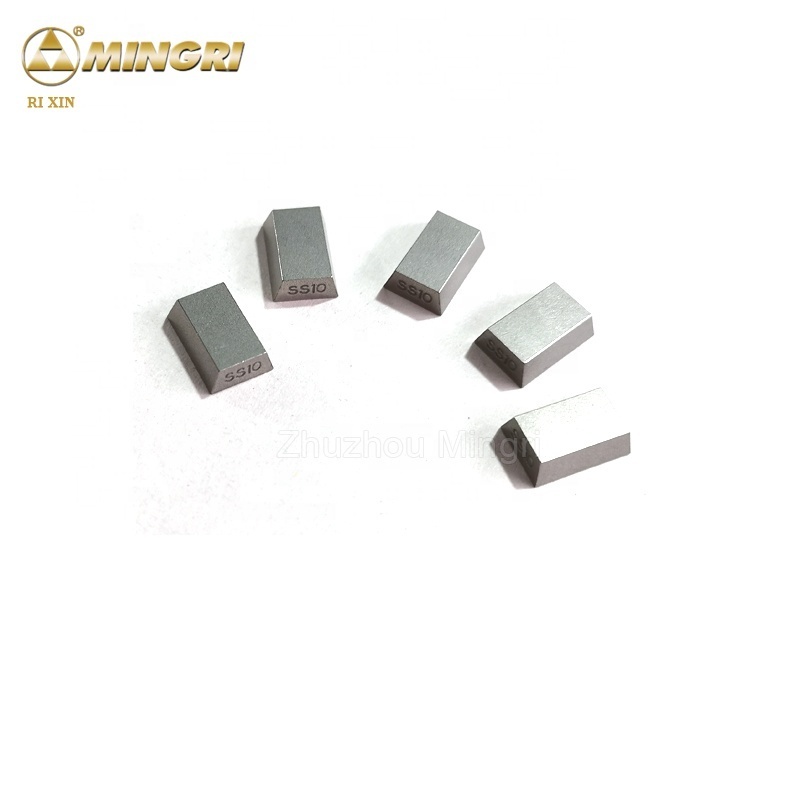

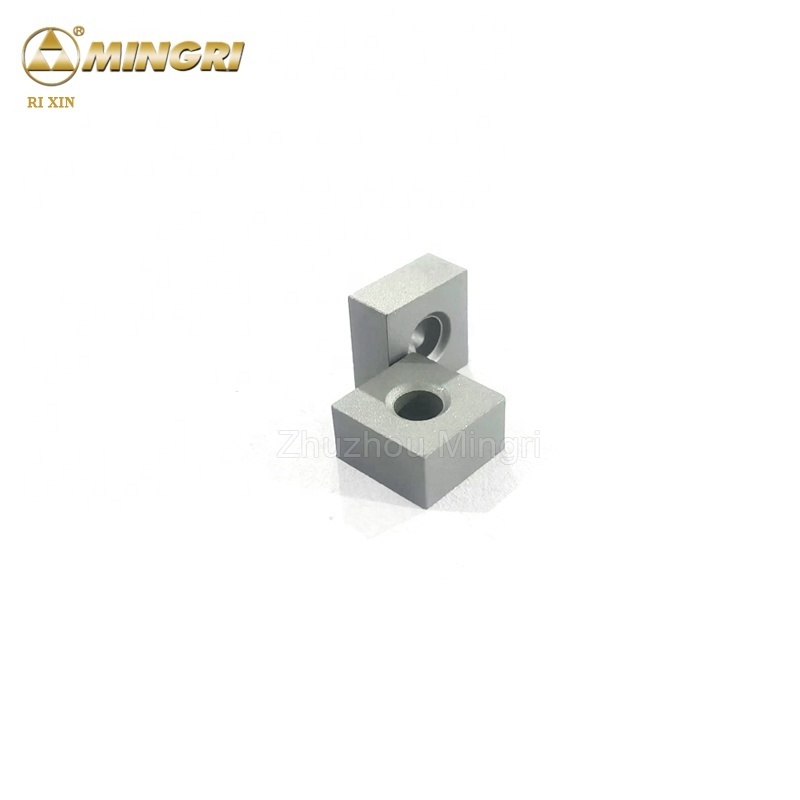

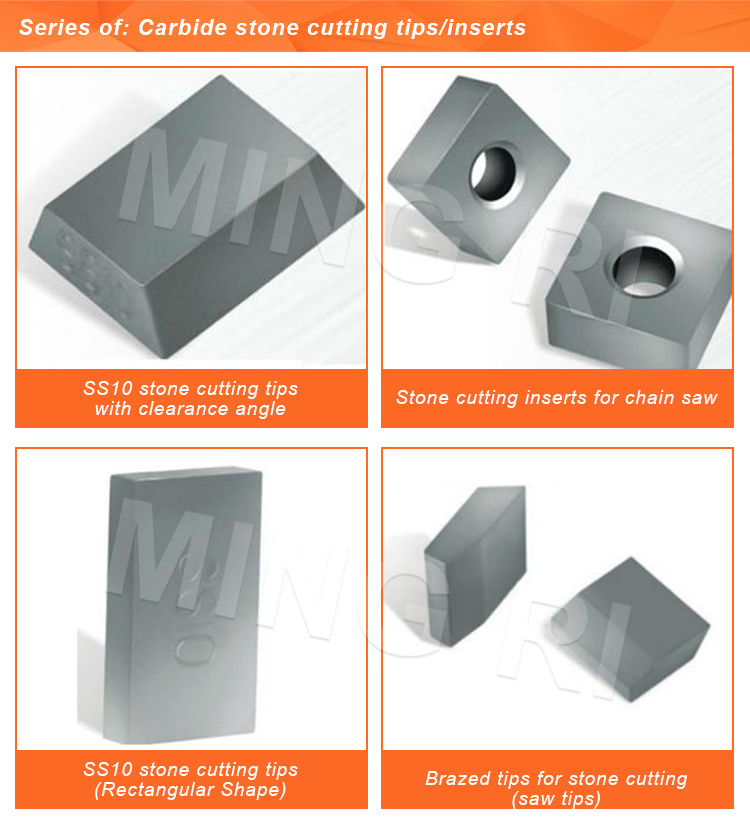

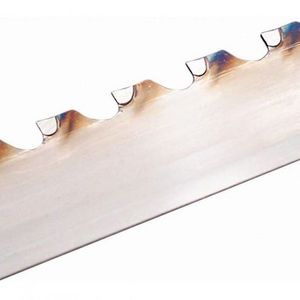

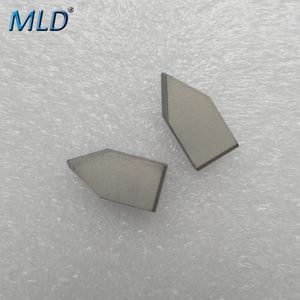

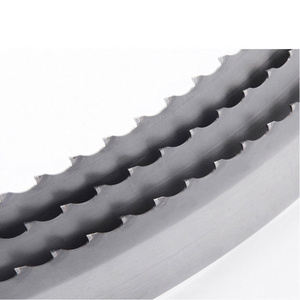

Tungsten Carbide Stone Cutting Tips Manufacturer, K20 Tungsten Carbide Tips SS10 Stone Cutting Tips

| Item | Tungsten carbide SS10 Stone Cutting Tips |

| Grade | YG6, YG8, YG10, BK8, MR06H |

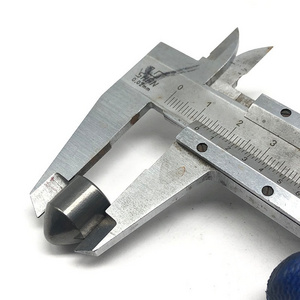

| Sizes | 15x10x5, 20x12x3, 12.7X12.7X6.5 |

| Brand | Rixin |

| Country of Origin | Zhuzhou, China |

| Usage | cutting stone |

SS10 carbide tips to be welded onto the seats on the blades for stone cutting machines, it can be used for the processing of various kinds of stones, such as limestone, sandstone, tufa stone, granite etc.

2. Dark grey surface with hot sale at Kenya, Egypt and Libya market;

3. Precision dimensions with good unit weight and size accuracy;

4. Various sizes and types for your choice;

5. Longstanding old customers with over tons export amount every month.

Grade & application for welding tips

|

Grade |

ISO Code |

Density

|

Hardness

|

T.R.S

|

Applications recommended |

|

YG3 |

K05 |

15.10 |

92.0 |

1400 |

Suitable for finishing of cast iron and nonferrous metal. |

|

YG6X |

K10 |

14.95 |

91.5 |

1800 |

The finishing & semi-finishing of cast iron and nonferrous metals and also for the machining of manganese steel and hardening steel. |

|

YG6 |

K15 |

14.95 |

90.5 |

1900 |

Suitable for the roughing of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

|

YG8 |

K20 |

14.80 |

89.5 |

2200 |

|

|

YW1 |

M10 |

13.10 |

91.6 |

1600 |

Suitable for finishing and semi-finishing of stainless steel and conventional alloy steel. |

|

YW2 |

M20 |

13.00 |

90.6 |

1800 |

The grade can be used for the semi-finishing of stainless steel and low-alloy steel and it is mainly used for the machining of railway wheel hubs. |

|

YT15 |

P10 |

11.4 |

91.5 |

1600 |

Suitable for the finishing and semi-finishing for steel and cast steel with a moderate feed rate and rather high cutting speed. |

|

YT14 |

P20 |

11.6 |

90.8 |

1700 |

Suitable for the finishing and semi-finishing of steel and cast steel. |

|

YT5 |

P30 |

12.9 |

90.5 |

2200 |

Suitable for the heavy duty rough turning of and cast steel with a big feed rate at a medium and low speed under unfavorable working conditions. |

Other sizes can be offered aacording to customers requirements.

| Packing |

Paper+paper boxes+exported wooden cartons or paper cases.

As a manufacturer, Mingri can provide any kinds of package as buyer's requirement. |

| Shipping |

UPS,TNT,EMS,Fedex,DHL,or as you request. |

| Delivery |

7-10 days after confirm all details. |

We are specialized in all kinds of tungsten carbide profiles and dies, cutting tools, mining tools, wear parts and all kinds of non-standard customized tool parts with high performance in the industry.

Zhuzhou Mingri Cemented Carbide Co., Ltd was established in 2001 with the investment of 10 million dollars, area of 33300 square meters and 160 staffs. We have obtained 35 patents in invention, utility model and design , and passed ISO9001:2015 Certification in quality and GB/T 24001-2004/ISO 14001:2004 Certification in environment. offering all kinds of high quality tungsten carbide products and technical services to all clients. Our products are exported to US, Europe, Japan, Taiwan and South-east Asia etc. We have won support and trust from customers both home and abroad.

Workshop

We have powder mixing, pressing, sintering, finishing, surface treatment, mould design workshops and physical and chemical labs for inspection. We have hundreds of updated equipments to make sure month capacity 50 tons and excellent quality.

How to ensure the high quality standard?

Do you want to know the details?

Please follow......

Production & Testing

All the products must be inspected strictly with the ultrasonic and only those haven't any harm such as pore can be shipped out. High density, high wear & impact resistance, which lead them a long lifetime.

We passed ISO9001:2000 in 2003 and keep improving the quality everyday. We have been always trying our best to provide our customers with high quality, the best price and satisfactory service.

Team and Exhibitions

Any detailed information needed, please feel free to contact us! We will reply to you ASAP!!!