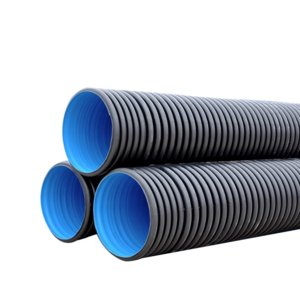

It has a bell and spigot design, so it is also self-coupling. It provides superior corrosion and abrasion resistance making it an excellent alternative to reinforced concrete and corrugated metal pipe.It works very well as plastic culvert pipe for driveways.

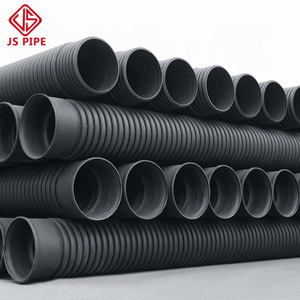

DWC Pipes are available in SN 4 and SN 8 stiffness classes with sizes from 100 mm to 800 mm ID. These pipes have a standard

length of 6 metre and are available with rubber ring jointings.

length of 6 metre and are available with rubber ring jointings.