- Product Details

- {{item.text}}

Quick Details

-

Color:

-

Dark red or paint as required

-

Application:

-

Used as iron ore concentration plant

-

Adaptability:

-

Strong

-

Structure:

-

Reasonable

-

Maintenance:

-

Convenient

-

Running cost:

-

Low

-

Operation:

-

Easy

-

Running State:

-

Stable

-

Certification:

-

CE, ISO9001

Quick Details

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training

-

Installation:

-

under engineer's guidance

-

Color:

-

Dark red or paint as required

-

Application:

-

Used as iron ore concentration plant

-

Adaptability:

-

Strong

-

Structure:

-

Reasonable

-

Maintenance:

-

Convenient

-

Running cost:

-

Low

-

Operation:

-

Easy

-

Running State:

-

Stable

-

Certification:

-

CE, ISO9001

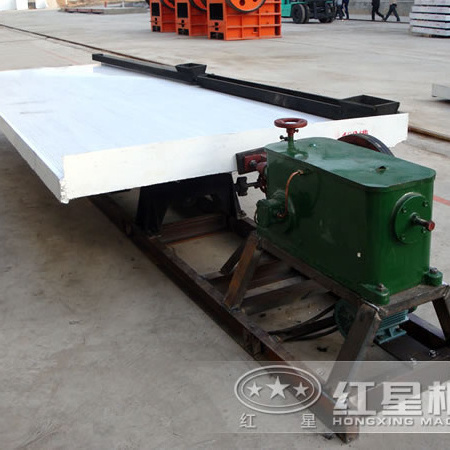

2014 Hot Sale Low Price High Efficiency Density

Small Gold Shaker Table

Advantages of High Efficiency Density Small Gold Shaker Table

1.Higher Recoveries & Concentrate Yield

2.Greater Feed Capacity, More Tonnage/Day

3.4-Models to choose from, both Diagonal deck and Rectangular deck design

4.Deck Construction with Highest Quality of Water proof Teak Marine Wood

5.Continuous and un-interrupted Feed Cycle, resulting in higher recovery, time saving and costs

6.Highest Quality Anti-friction Head Motion

7.Modern and efficient Anti-friction Head Motion mechanism, self-oiling and splash-proof

8.Highest Quality Material Fabrication

9.Lowest ownership cost

10.standard One-Year Warranty

----------------------------------------------

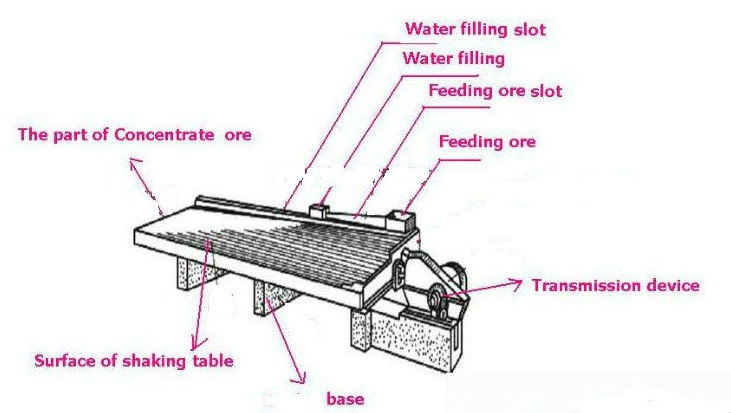

Working Principle of High Efficiency Density Small Gold Shaker Table

Table concentrator consists of Head Motion, Decks, frame, Feed and Water Box. When operate table concentrator, the ore grains laminate surface and according to the proportion and granularity, and make the longitudinal motion and transversal motion along the bed surface, in function of the gravity, the crosswise running water momentum, the inertia and friction force from the reciprocation symmetry movement of bed surface. Therefore, the proportion and the granularity different ore grain assumes gradually along respective heading by A on the one hand to B on the other hand fan-shaped flows off, separately discharges from the ore concentrate end and the debris side different area, finally the material is divided into the ore concentrate, the middling and the debris.

1.Head Motion

6-S shaking tables are furnished with a totally enclosed self-oiling head motion of heavy cast iron to contain an oil reservoir for perfect splash lubrication. This feature protects the moving parts, reducing operating and maintenance costs to a minimum.

2.Decks

The decks are constructed of steel framework and covered 16mm fiberglass with corundum, this cover its strength reaches as high as 70% of steel, the features of this design are stronger, wear-resistant, corrosion-resistant, and no distortion, it lengthens the working-life of machine and thus allows machine perform perfectly on different mineral and different weather condition.

3.Technical Specification

The 6-S Shaking Tables have three distinct deck designs available. The course ore deck is designed for recovering particles size from 0.5 mm to 2 mm; the fine sand deck is designed for recovering fine particles in the range of 0.074 mm to 0.5 mm; the slime deck is designed for recovering super extremely fine particles in the range of 0.05 mm to 0.074 mm.

4.Feed and Water Box

A wooden feed distributing box with hopper and long water box are attached to the iron of the deck, giving a very even distribution of feed and water

|

Name

|

Unit

|

Grit concentrator table

|

Fine sand concentrator table

|

Sludge concentrator table

|

|

|

Dimensions

|

Length

|

MM

|

4450

|

4450

|

4450

|

|

Driving part width

|

MM

|

1855

|

1855

|

1855

|

|

|

Concentrate part width

|

MM

|

1546

|

1546

|

1546

|

|

|

Max.feeding size

|

MM

|

2

|

0.5

|

0.15

|

|

|

Feeding amount

|

T/d

|

30-60

|

10-20

|

15-25

|

|

|

Feeding thickness

|

%

|

25-30

|

20-25

|

15-25

|

|

|

Journey

|

MM

|

16-22

|

11-16

|

8-16

|

|

|

Frequency

|

F

|

15-48

|

48-53

|

50-57

|

|

|

Water quantity

|

T/d

|

80-150

|

30-60

|

10-17

|

|

|

Horizontal obliquity

|

Degree

|

2.5-4.5

|

1.5-3.5

|

1-2

|

|

|

Portrait obliquity

|

%

|

1.4

|

0.92

|

----

|

|

|

Table board corner

|

Degree

|

32-42

|

40

|

42

|

|

|

Concentrating square

|

----

|

7.6

|

7.6

|

7.6

|

|

|

Table board length ratio

|

----

|

2.6

|

2.6

|

2.6

|

|

|

Motor power

|

KW

|

1.1

|

1.1

|

1.1

|

|