- Product Details

- {{item.text}}

Quick Details

-

Feeding size:

-

Less than 180mm

-

Output size:

-

Less than 5mm

-

Adjustable of discharge gate gap:

-

5-20mm

-

Cement clinker:

-

35-40mm

-

Limestone:

-

45-55mm

-

Power:

-

37-45 kw

-

Function:

-

Sand Making Machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Name:

-

Good Comments Impact Crusher For Secondary Crushing Supplier

-

Rotor diameter*Length:

-

800*600mm

-

Feeding size:

-

Less than 180mm

-

Output size:

-

Less than 5mm

-

Adjustable of discharge gate gap:

-

5-20mm

-

Cement clinker:

-

35-40mm

-

Limestone:

-

45-55mm

-

Power:

-

37-45 kw

-

Function:

-

Sand Making Machine

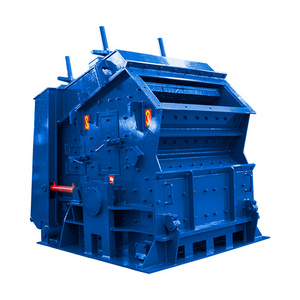

Good Comments Impact Crusher For Secondary Crushing Supplier, PXJ Secondary Crushing Machine

Introduction of Zircon Sand Impact Crusher, Hard Materials Fine Impact Crusher

Tertiary crusher is widely used for the fine crushing of many kinds of minerals such as granite, basalt, limestone, river cobble, cement clinker, quartz stone, iron ore and bauxite, and at the same time, it can also be used for producing excellent stone materials in artificial sand making, high-grade highway, railway, water conservancy, airport, building, cement, refractory and metallurgical industry.

Application Of Zircon Sand Impact Crusher, Hard Materials Fine Impact Crusher

Fine Crusher is used to crush brittle materials, like gangue, coke, slag, red sandstone, shale, loose limestone, etc. The compressive strength of the material does not surpass 100Mpa; the surface waters no more than 15%.

Features of Zircon Sand Impact Crusher, Hard Materials Fine Impact Crusher

Tertiary crusher is suitable for the fine crushing and medium crushing of man many kinds of hard and crisp materials such as refractory, cement, silica sand and steel grit. It is highly efficient and energy saving, and saves energy by 50% compared with traditional tertiary impact crusher, so that it is the most advanced tertiary impact crushing equipment in the world.

Advantages of

Zircon Sand Impact Crusher, Hard Materials Fine Impact Crusher

1. Large feeding size and high crushing ratio.

2. Perfect cubic shape product and stable structure.

3. Convenient discharge opening adjustment for different products size.

4. High chromium hammer and unique lining plate suitable to crush hard stones efficiently.

5. Long service life of hammers, impact plates and lining plates.

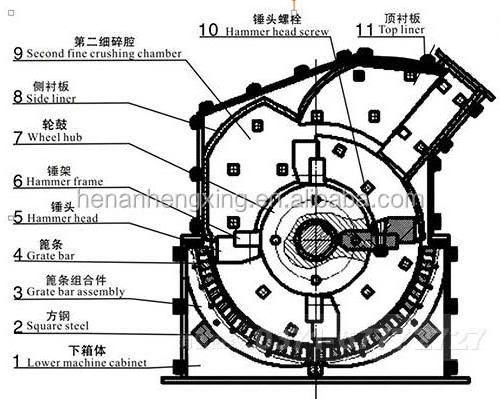

Principle of Zircon Sand Impact Crusher, Hard Materials Fine Impact Crusher

When the tertiary impact crusher works, driven by the electromotor, the rotor rotates with high speed, and the materials go into the first crushing chamber and are crushed with the plate hammer of the rotor, and then go into the secondary crushing chamber for grinding, and finally the materials are discharged from the discharging mouth.

Structure Drawing of Zircon Sand Impact Crusher, Hard Materials Fine Impact Crusher

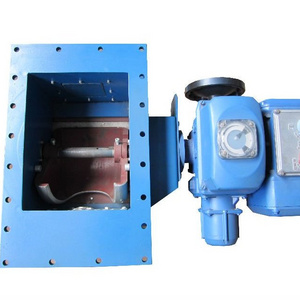

Rotor of Zircon Sand Impact Crusher, Hard Materials Fine Impact Crusher

Final Product of Zircon Sand Impact Crusher, Hard Materials Fine Impact Crusher

Workshop Picture of Zircon Sand Impact Crusher, Hard Materials Fine Impact Crusher

Different model of Zircon Sand Impact Crusher, Hard Materials Fine Impact Crusher

Work site of Zircon Sand Impact Crusher, Hard Materials Fine Impact Crusher

Parameters of Zircon Sand Impact Crusher, Hard Materials Fine Impact Crusher

|

Model |

Feeding size(mm) |

Discharging size(mm) |

Capacity(t/h) |

Power(kw) |

Weight(t) |

|

PXJ800×400 |

≤60 |

≤5 (96%) |

20-25 |

37 |

2.5 |

|

PXJ800×600 |

≤60 |

≤5 (94%) |

35-50 |

45 |

4.7 |

|

PXJ800×800 |

≤70 |

≤5 (92%) |

40-60 |

75 |

6.5 |

|

PXJ1000×1000 |

≤80 |

≤5 (91%) |

60-90 |

90 |

8.8 |

|

PXJ1000×1200 |

≤90 |

≤5 (88%) |

75-110 |

110 |

13.6 |

|

PXJ1200×1200 |

≤100 |

≤5 (86%) |

120-145 |

160 |

19.5 |

|

PXJ1300×1400 |

≤120 |

≤5 (85%) |

145-180 |

180 |

26 |