- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Hiwinstar

-

Voltage:

-

220V/380V

-

Weight (KG):

-

8000 KG

-

Power (kW):

-

48

-

Dimension(L*W*H):

-

3500*1700*1800mm

-

Number of Layers:

-

4

-

Applicable Industries:

-

furniture workshop

-

Name:

-

hot press machine for plywood

-

Spare parts:

-

Durable

-

Color:

-

Customer Requirements

-

Model:

-

MH3848*3

-

Woodworking Machine:

-

Hot Press

-

Working pressure:

-

120T

-

Layers of platen:

-

3 layers

-

Hot platen size:

-

1200*1200*42mm

-

Weight:

-

8000kg

-

Overall dimensions:

-

3500*1700*1800mm

Quick Details

-

Max.Pressure(T):

-

120T

-

Working Table Size(mm):

-

1250×2500

-

Pressure:

-

120T

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Hiwinstar

-

Voltage:

-

220V/380V

-

Weight (KG):

-

8000 KG

-

Power (kW):

-

48

-

Dimension(L*W*H):

-

3500*1700*1800mm

-

Number of Layers:

-

4

-

Applicable Industries:

-

furniture workshop

-

Name:

-

hot press machine for plywood

-

Spare parts:

-

Durable

-

Color:

-

Customer Requirements

-

Model:

-

MH3848*3

-

Woodworking Machine:

-

Hot Press

-

Working pressure:

-

120T

-

Layers of platen:

-

3 layers

-

Hot platen size:

-

1200*1200*42mm

-

Weight:

-

8000kg

-

Overall dimensions:

-

3500*1700*1800mm

Mh3848*5 Woodworking Hydraulic Melamine Laminating Laminated Wooden Door Veneer Hot Press Machine

| model no | MH3848*1 | MH3848*2 | MH3848*3 |

| working pressure | 120T | 120T | 120T |

| platen dimension | 2500*1300mm | 2500*1300mm | 2500*1300mm |

| platen of oil cylinder | ø100*8pcs | ø100*8pcs | ø100*8pcs |

| layer of platen | 1 layer | 2 layers | 3 layers |

| opening of platen | 380mm | 170mm | 100mm |

| heating power | 27kw | 45kw | 54kw |

| hydraulic system power | 5.5kw | 5.5kw | 5.5kw |

| heating oil pump power | 1.5kw | 2.2kw | 2.2kw |

| weight | 6485kw | 7400kg | 8500kg |

| overall dimensions | 3700*1660*2100mm | 3700*1660*2100mm | 3700*1660*2100mm |

Hydraulic hot press, mainly with the temperature selection, technical control and processing of product quality and so on. The traditional heating method, usually the choice of steam heating and electric heating of the two, the former simple

Board temperature is not uniform and other issues, while the latter, there are large power consumption, operating costs of high-level features. Later, there are heating oil heating and other methods. This heating method, its high heat capacity, uniform temperature and heat loss

So that it can reduce the production cost and be able to reach the desired hot pressing effect.

Features

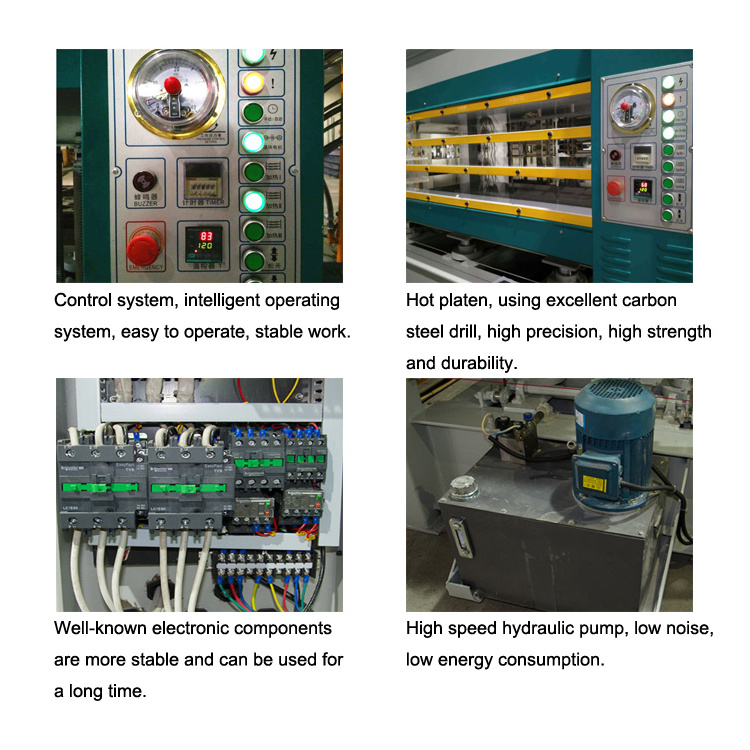

1,Control system, intelligent operating system, fitting machine, easy to operate, stable work.

2,Hot platen, using excellent carbon steel drill, high precision, high strength and durability.

3,Well-known electronic components are more stable and can be used for a long time.

4,Hydraulic pump,reduce noise,low energy consumption,high speed.

Detailed Description

Detailed Pictures

Application

Apply for furniture, wooden door factory, man-made board production manufacturers secondary processing face, used to hot glue furniture plate, building partition door, fire door surface materials, wood veneer.In man-made board, plywood, joinery board, MDF, particle board, surface pressure on all kinds of decorative materials, decorative cloth, wood veneer, PVC, etc., can also be used for veneer drying, leveling, color decoration wood leveling, finalize the design, the effect is remarkable.