- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

apollo

-

Voltage:

-

220v 0r 380v

-

Dimension(L*W*H):

-

5.4*2.5*4.5m

-

Screw diameter (mm):

-

100 mm

-

Screw Heating Power(kW):

-

15 kW

-

Extruder Motor Power(kW):

-

15 kW

-

Mold Platen Size(Width)(mm):

-

600 mm

-

Mold Platen Size(Height)(mm):

-

655 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

1.5 m³/min

-

Die Head Heating Power(kW):

-

15 kW

-

Accumulator Capacity(L):

-

25 L

-

Power (kW):

-

15

-

Weight (T):

-

15

-

application:

-

bottle, jar,can, tank, chair,ball, pallet ,tool box

-

screw diameter:

-

100mm

-

output capacity:

-

40~50 pcs/h

-

Max.product volume:

-

160L

-

Material:

-

HDPE LDPE LLDPE

-

Screw diameter:

-

110MM

-

Screw heating capacity:

-

25KW

-

Max.size of mold:

-

1000*1600

-

Template size:

-

1150*1600

-

Mold stroke:

-

550-1350

Quick Details

-

Clamping Force (kN):

-

230

-

Output (kg/h):

-

60 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

apollo

-

Voltage:

-

220v 0r 380v

-

Dimension(L*W*H):

-

5.4*2.5*4.5m

-

Screw diameter (mm):

-

100 mm

-

Screw Heating Power(kW):

-

15 kW

-

Extruder Motor Power(kW):

-

15 kW

-

Mold Platen Size(Width)(mm):

-

600 mm

-

Mold Platen Size(Height)(mm):

-

655 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

1.5 m³/min

-

Die Head Heating Power(kW):

-

15 kW

-

Accumulator Capacity(L):

-

25 L

-

Power (kW):

-

15

-

Weight (T):

-

15

-

application:

-

bottle, jar,can, tank, chair,ball, pallet ,tool box

-

screw diameter:

-

100mm

-

output capacity:

-

40~50 pcs/h

-

Max.product volume:

-

160L

-

Material:

-

HDPE LDPE LLDPE

-

Screw diameter:

-

110MM

-

Screw heating capacity:

-

25KW

-

Max.size of mold:

-

1000*1600

-

Template size:

-

1150*1600

-

Mold stroke:

-

550-1350

1 MACHINE FEATURES

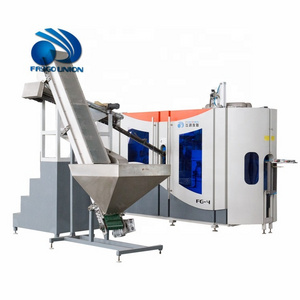

Extrusion Blow Molding Machine

ABLD 120 Instruction

ABLD 120 is single station automatic extrusion blow machine for 300L as maximum,

specially used for 100~300L plastic drums, barrels and containers of packing or other industrial liquid.Equiped with Japanese Mitsubishi PLC&temperature controller,Schneider contactor,Delta or ABB invertor,Siemens Motor,Hitech oil pump,Original Japan MOOG 100 points parsion controller.

2 MACHINE MODEL APPEARANCE

3 TECHNICAL PARAMETER

|

Name

|

Units

|

ABLD120

|

|

Dry cycle

|

PC/H

|

300

|

|

Screw diameter

|

MM

|

120

|

|

Screw L/D ratio

|

L/D

|

33

|

|

Screw drive power

|

KW

|

132

|

|

Screw heating capacity

|

KW

|

36

|

|

No.of heating zone

|

ZONE

|

6

|

|

Output of HDPE

|

KG/H

|

350

|

|

Oil pump drive power

|

KW

|

37

|

|

Clamping force

|

KN

|

900

|

|

Max size of mold

|

MM

|

1200*1700

|

|

Template of size

|

MM

|

1200*1600

|

|

Mold stroke

|

MM

|

880-1700

|

|

Max die diameter

|

MM

|

700

|

|

Blow pressure

|

MPA

|

0.8

|

|

Air volume

|

M3/min

|

1.6

|

|

Cooling water pressure

|

MPA

|

0.3

|

|

Water consumption

|

L/min

|

180

|

|

Size of machine

|

L*W*H

|

7.5*3.5*5.5

|

|

Weight of machine

|

TON

|

36

|

4 MACHINE CONFIGURATION

5 RELATED PRODUCTS

6 WHY CHOOSE US

7 WHAT ELSE CAN WE DO FOR YOU

8 LOADING DELIVERY

Changeable heads, metal parts, big and heavy parts are packaged with 3-ply boxes, which will be nailed into container floor with

angle iron board, or fastened with special hooks and belts to avoid sliding or impacting.

Main machine or dismantled machine frames with feet screw bolts into container floor to avoid sliding, with special belt and hooks

to lock the 4 corners for positioning to avoid impact damages during translation.

Spare parts, tools & small goods, Moulds and auxiliary machines are packaged with 5-ply boxes, placed well and tightly according

to loading sketch to save loading space, finally with nailed iron boards or belt to fasten them together.

Hot Searches