- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hongfa

-

Voltage:

-

220/380/440V

-

Weight:

-

18000 KG

-

Product Name::

-

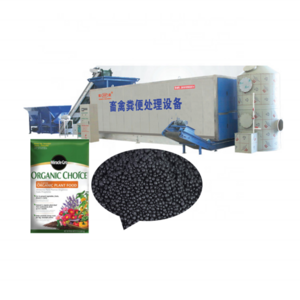

Organic Fertilizer Granulator Machine

-

Keywords::

-

Organic Fertilizer Equipment

-

Applicable Industries::

-

Farms, Organic fertilizer production line

Quick Details

-

Application:

-

Farms, Organic fertilizer production line

-

Production Capacity:

-

3000/h

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

220/380/440V

-

Weight:

-

18000 KG

-

Product Name::

-

Organic Fertilizer Granulator Machine

-

Keywords::

-

Organic Fertilizer Equipment

-

Applicable Industries::

-

Farms, Organic fertilizer production line

Hongfa High Quality Granulator Fertilizer Machine to Produce Compost from Organic Waste

Hongfa Machinery since 1990

A leader developer& Manufacturer of Construction Material Machinery.

Guangxi production base: 9 machinery factories

Updated to state-owned enterprise.

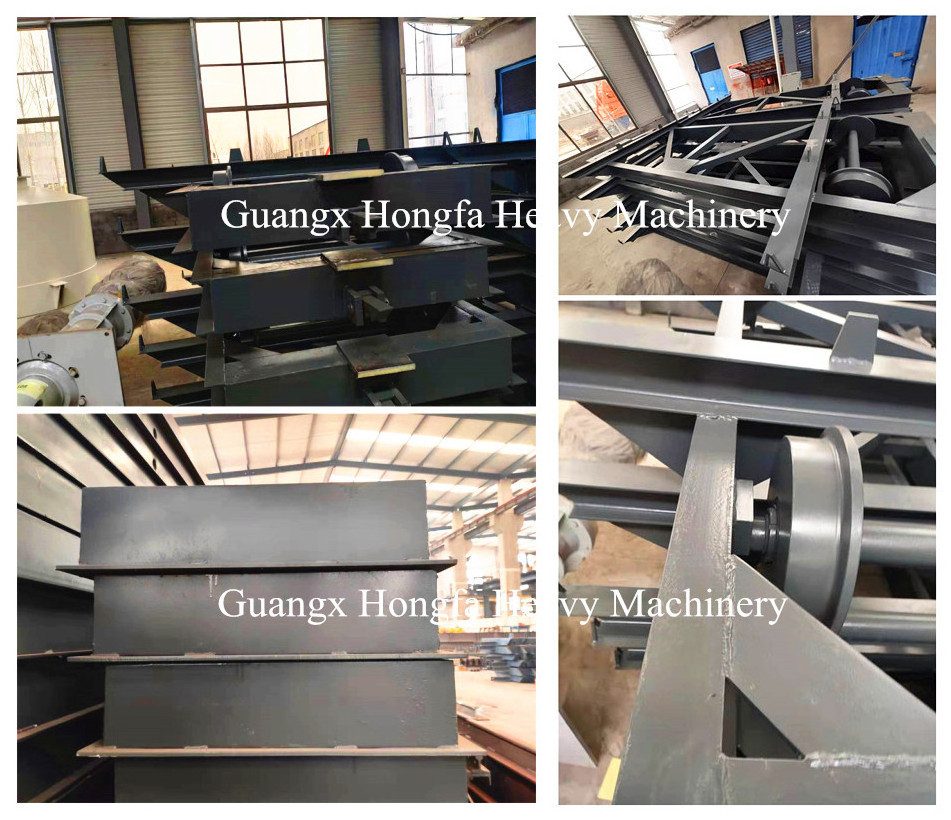

-Raw equipment material of Hongfa Updated Bedtype fermentation

The main structure of the equipment frame is galvanized steel and pickled and phosphated steel,

and the whole frame is sprayed with special materials, which greatly increases the service life of

th e equipment. The contact position of the fermentation bed and feces is all made of 304 stainless

steel including screws.

To make our Organic Fertilizer Machine reliable and durable, HONGFA FACTORY purchases

steel from famous steel manufacturers in China. We only use steel plates that have not been

rolled.

Hongfa QC Dept. will test our Fertilizer production line at least three times before shipping.

-The operating principle of the Granulator Fertilizer Machine Chemical Npk Fertilizer Granulator Machine Price Organic Manure Pelletizer

Adopts the heat generated by natural fermentation of feces, and the heat is efficiently recovered to continuously support the stability of the overall fermentation. Each raw material of the

fermentation requires about 7 to 10 degrees of electricity. When the temperature is low, an electromagnetic heating auxiliary system is used. The raw materials are fermented in the equipment for 48 hours to achieve deodorization,

insecticide, decomposing, and low moisture content in the fertilizer.

-Working Process of producing organic fertilizer from manure:

Raw material fermentation-Raw material crushing- Raw material mixing -Raw material

drying-feriizer

granulating -Ferilizer Cooling-Ferilizer coating- Ferilizer packing

Hongfa provide kinds of High Quality Organic Fertilizer production Line for Livestock and Poultry Manure Treatment Garbage Organic Fertilizer Waste Fermentation Aerobic Digester Compost making Machine Sludge Garbage Organic Fertilizer Plant Chicken Manure Processing Equipment Pig Cattle and Sheep Manure Fermentation tank organic fertilizer making production line high temperature aerobic fermentation equipment Fertilizer making cattle wastes cow manure organic compost making machine.

|

11FFC livestock and poultry manure intelligent integrated treatment machine parameters |

||||||

| Parameter model | 11FFC-10 | 11FFC-20 | 11FFC-40 | 11FFC-60 | 11FFC-100 | 11FFC-200 |

| Host effective volume | 10 m³ | 20 m³ | 40 m³ | 60 m³ | 100m² | 200 m² |

| Total motor power | 32kw | 35kw | 40kw | 45kw | 55kw | 87kw |

| Monitor rate | 8kw | 8kw | 11kw | 11kw | 15kw | 30kw |

| Batching machine | 2.2kw*2 | 3kw*2 | 3kw*2 | 3kw*4 | 15kw | 15kw |

| How to eliminate the Olympics | biological, spray | biological, spray | biological, spray | biological, spray | biological, spray | biological, spray |

| Moment removal circulating water pump | 1.1kw | 2.2kw | 2.2kw | 2.2kw | 2.2kw | 3kw2 |

| It can be designed and produced according to user requirements, and the parameters are for reference only. | ||||||

After the biological strains independently developed by Hongfa Environmental Protection

are combined with the feces, the feces are put into the box on the same day, and the odor can be deodorized on the same day. Based on the combination of dynamic and static high-temperature fermentation process, while eliminating eggs and sterilizing, the feces undergo

high-temperature aerobic fermentation in the equipment for 1-2 days, and after being placed, organic fertilizer meeting the national organic fertilizer standard will be produced.

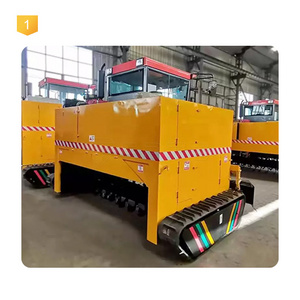

Roulette tipping machine

The roulette tipping machine equipment adopts the intermediate chain transmission mechanism, driving the two diameters of the tipping wheel, symmetrical flipping, no dead angle adjustable speed shift trolley, left and right displacement, low energy consumption to complete the long-span tipping work.

Application advantages of organic-inorganic compound fertilizer

1. Improve fertilizer utilization: Organic-inorganic compound fertilizer is rich in humic acid, has obvious functions of dissolving phosphorus and potassium, storing water and retaining moisture, and can effectively activate the nitrogen, phosphorus and potassium deposited in the soil due to single application of chemical fertilizers.

2. Improve soil structure: Organic-inorganic compound fertilizer contains a large amount of organic matter, which can effectively improve soil aggregate structure, enhance soil permeability, improve soil water and fertilizer retention, and has a particularly obvious effect on increasing production of peanut and potato crops. 3. Improve the quality of agricultural products: The application of organic-inorganic compound fertilizers can greatly increase the content of fruit protein, amino acids, chlorophyll, vitamins and carbohydrates, reduce the content of nitrate and nitrite, and improve the appearance quality of crops. 4. Reduce environmental pollution: Organic-inorganic compound fertilizer can reduce nutrient leaching and volatilization, free of insect eggs, harmful bacteria, and heavy metal content far lower than national standards.

Smart factory for aerobic fermentation treatment of organic solid waste

Centralized processing center solution

Features of smart factory for aerobic fermentation treatment of organic solid waste: intelligent, automated, remote controllable, the entire fermentation process is designed in a closed air.

The room can be divided into four parts: mixing and deodorization, fermentation and ripening, air supply and exhaust, and monitoring and control. It has PLC intelligent automatic control of material mixing and connection.

It has the functions of deodorization, pile turning and aeration, temperature control and water control, ammonia oxygen monitoring, gas purification and other functions. It can be used as a centralized treatment center for large farms and regional manure.

Ideal solution. Daily processing capacity can be designed as needed.

Livestock and poultry fermentation treatment machine

Comparison of the advantages of Hongfa environmental protection and other equipment

Hongfa environmental protection equipment (bed type fermentation equipment)

1. Adopting patented design, direct oxygen into the material to be fermented to make it fully

fermented.

2. The materials are fermented in layers and cycles in the tank, and the three-zone separation technology is adopted at the bottom of the equipment to make the materials

more completely fermented.

3. The fermentation cycle is short, the feed is 8 hours to deodorize, and the fertilizer is

completed in 48 hours.

4. Low discharge water content.

5. One person operation saves time and manpower. Small footprint, low cost, simple and

convenient operation.

Shipping Hongfa High Quality Granulator Fertilizer Machine Chemical Npk Fertilizer Granulator Machine Price Organic Manure Pelletizer