For example, the exhaust fan is 7000CMH, then you will need ESP device of 8000CMH.

Usually 1-meter-long range hood requires 2000CMH to 2500CMH airflow. For example, Ana's range hood is 1.2m in width and 2m in length, then she will need an ESP of 4000CMH.

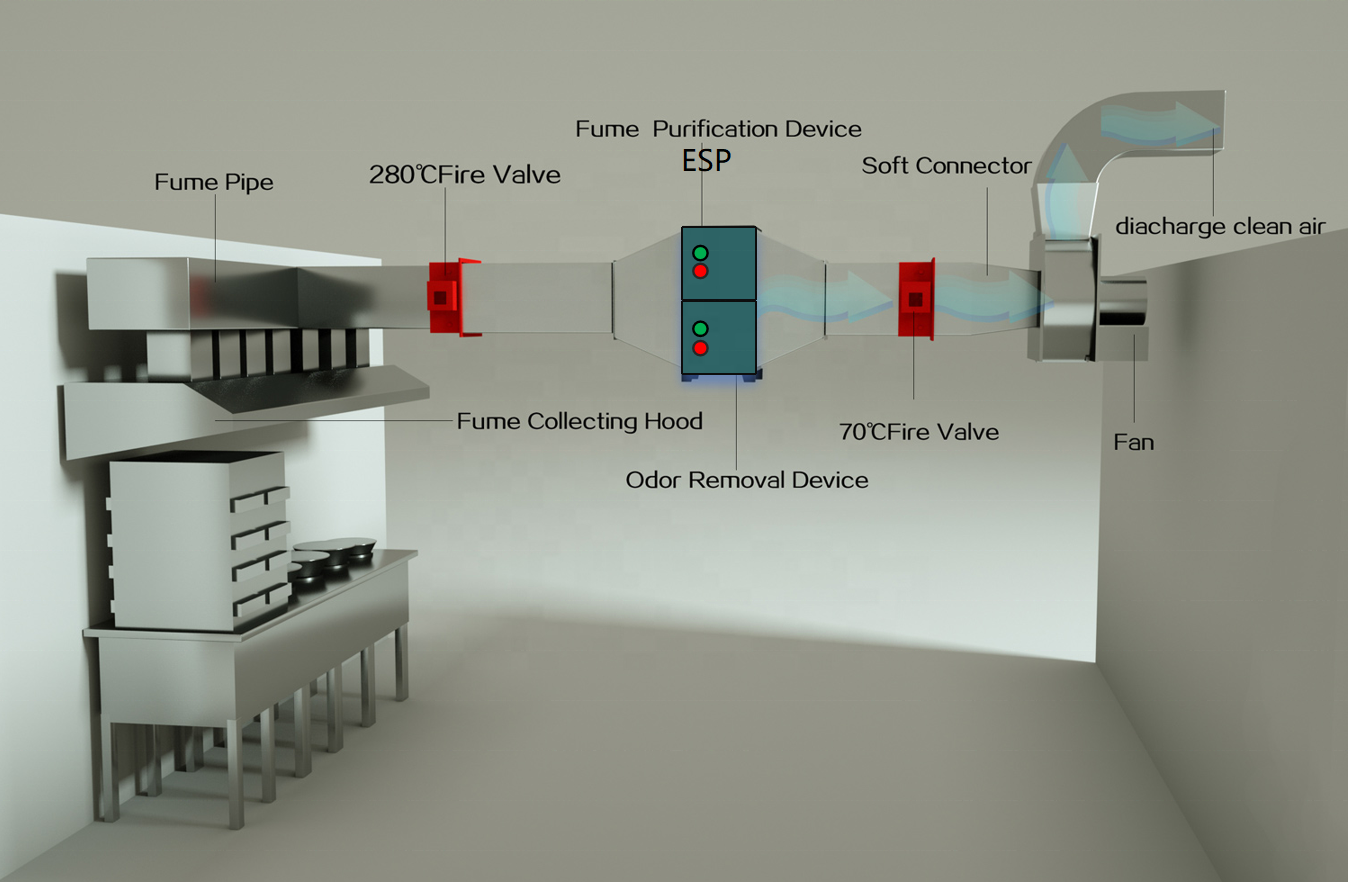

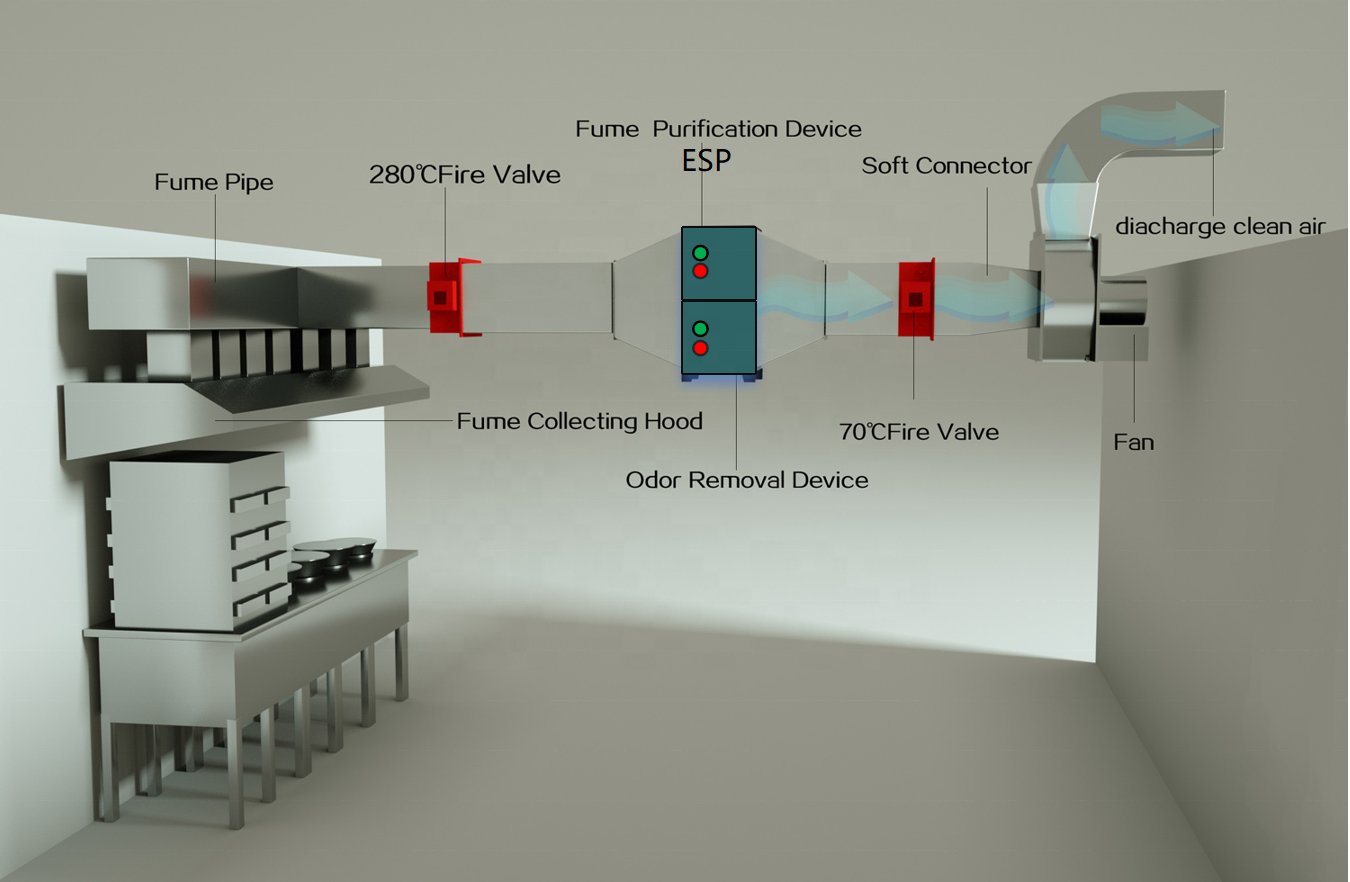

Cubic ESP device can be installed anywhere between range hood and exhaust fan.

For fire safety, we strongly suggest you put a fire damper after ESP device.

★4:

How often should I do the maintenance?

The maintenance is mainly about to clean the ESP Cell structure fume collectors. We

suggest the user shall clean the cells every 4-6 weeks. Or whenever the maintenance light lights up.

The ESP cell is removed and soaked in warm water for 30 minutes, then rinsed with water to dry before being returned to the machine. You can use detergent that is commonly used to remove oil stains at home.

★5:

An Electrostatic Precipitator offers many advantagesincluding:

1. Electrostatic Precipitator eliminates up to 95% single-pass efficiency of grease and smoke particles and double-pass configuration efficiency of 99.9% in the cooking exhaust system

2. Much lower operating costs. Electronic cells are simply washed to remove collected particulate and reused over and over. Because of this, there is a substantial saving by eliminating expensive replacement filters. ESPs are infinite.

3. Filters fine particles down to sub-micron levels which are better for pollution control

4. It’s a greener solution. Cells are cleaned and re-used which keeps greasy, spent media filters from filling up landfills.

5. Smaller footprint. Because of the high efficiency of the precipitator, there are fewer stages to the filtration process which makes these a good solution for space-limited projects.

6. Lower static pressure means smaller horsepower blowers and less power consumption.

7. The amount of grease and smoke in kitchen exhaust fumes is reduced to lessen the nuisance of smells to the neighbourhood. ESP systems give the restaurant a clean image while complying with local legislation.

8. Fire Risk Reduction. Greatly reduces grease and grease build-up within the kitchen exhaust ductwork and reduces fire risk.

With proper care and maintenance, an ESP system will provide decades of highly efficient filtration in a commercial kitchen exhaust application. With all things being considered, an ESP system is clearly the best option to use when a Pollution Control Unit is needed for the kitchen exhaust.

★6:

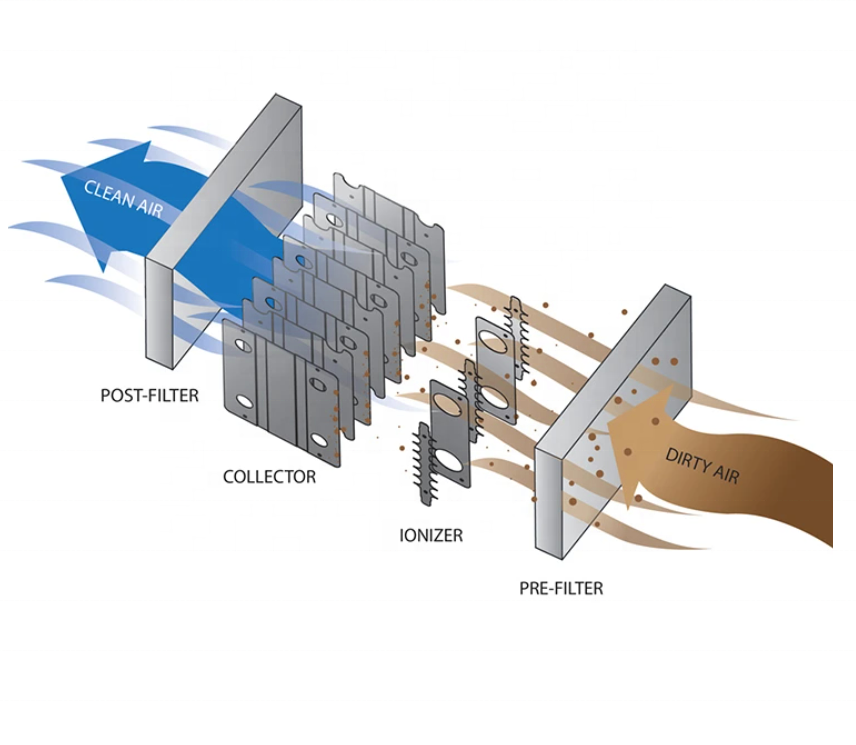

ESP, Electrostatic Precipitators for Pollution Control Units

These systems utilize something called an “ionizing-collector cell”; it resembles a box with a series of parallel plates in a frame about the size of a small trunk. There are typically multiples of these “cells” based on the total exhaust volume required. The front part of this box has an “ionizing” electrode that creates a positive charge. Behind that, there are plates with another positive charge and grounded plates between them. When grease particulate passes through this front part, the particles are positively charged. The positively charged grease is repelled to the ground plates by the positive charge plates and collects on them, taking the grease out of the air stream. The efficiency of an ESP is related to the surface area of the cells (more cell area, greater opportunity to collect grease), voltage gradient, and the method of ionization.