- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Forwon

-

Liquid Flow Rate:

-

4m3/h

-

Maximum Working Pressure:

-

67.5bar

-

Weight:

-

1 KG

-

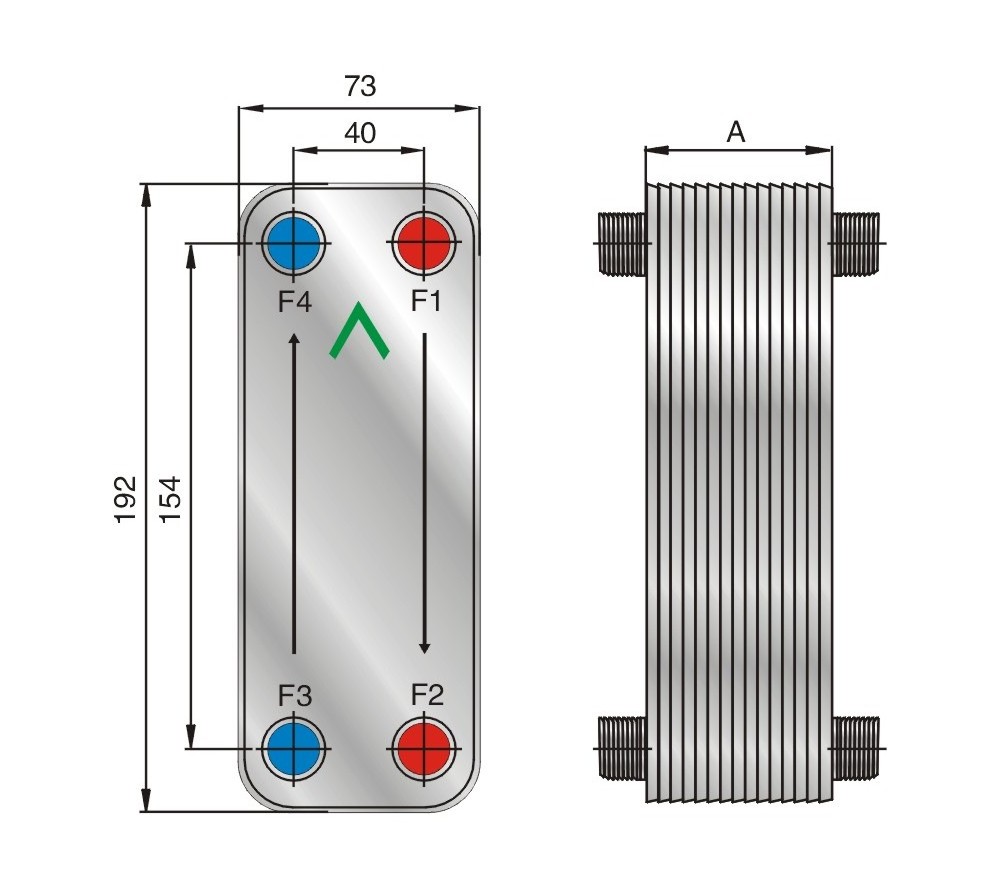

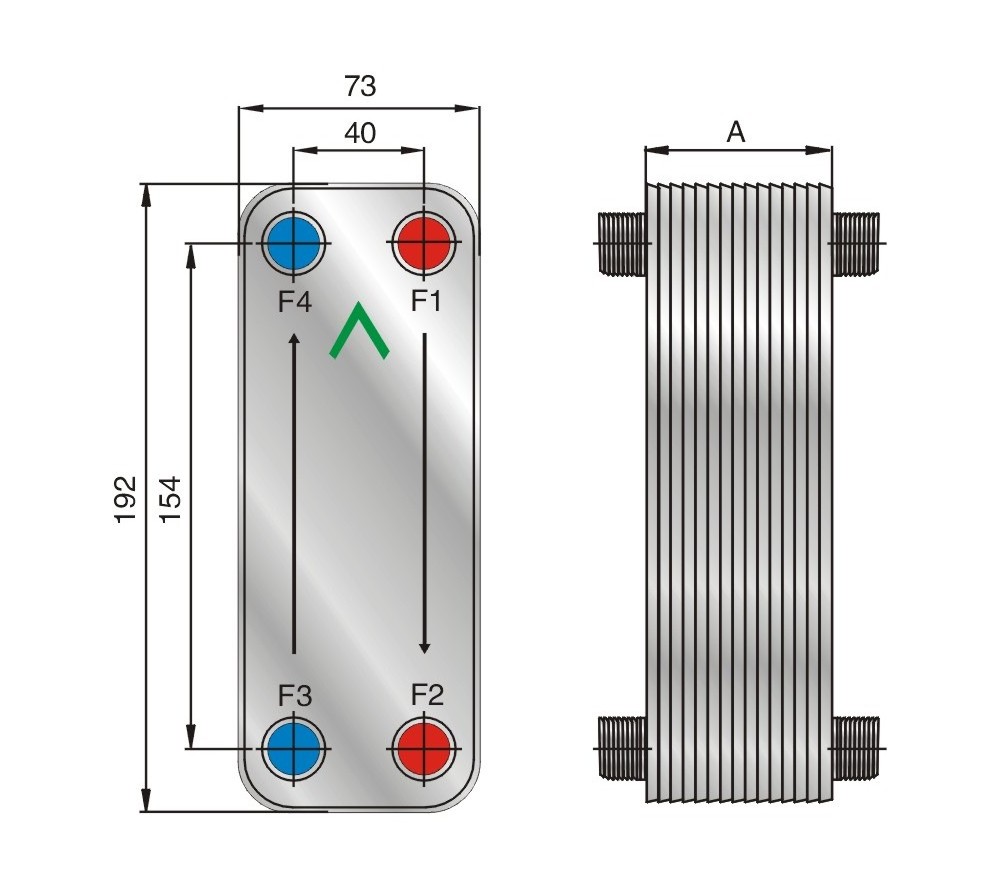

Dimension(L*W*H):

-

192*73mm

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

None

-

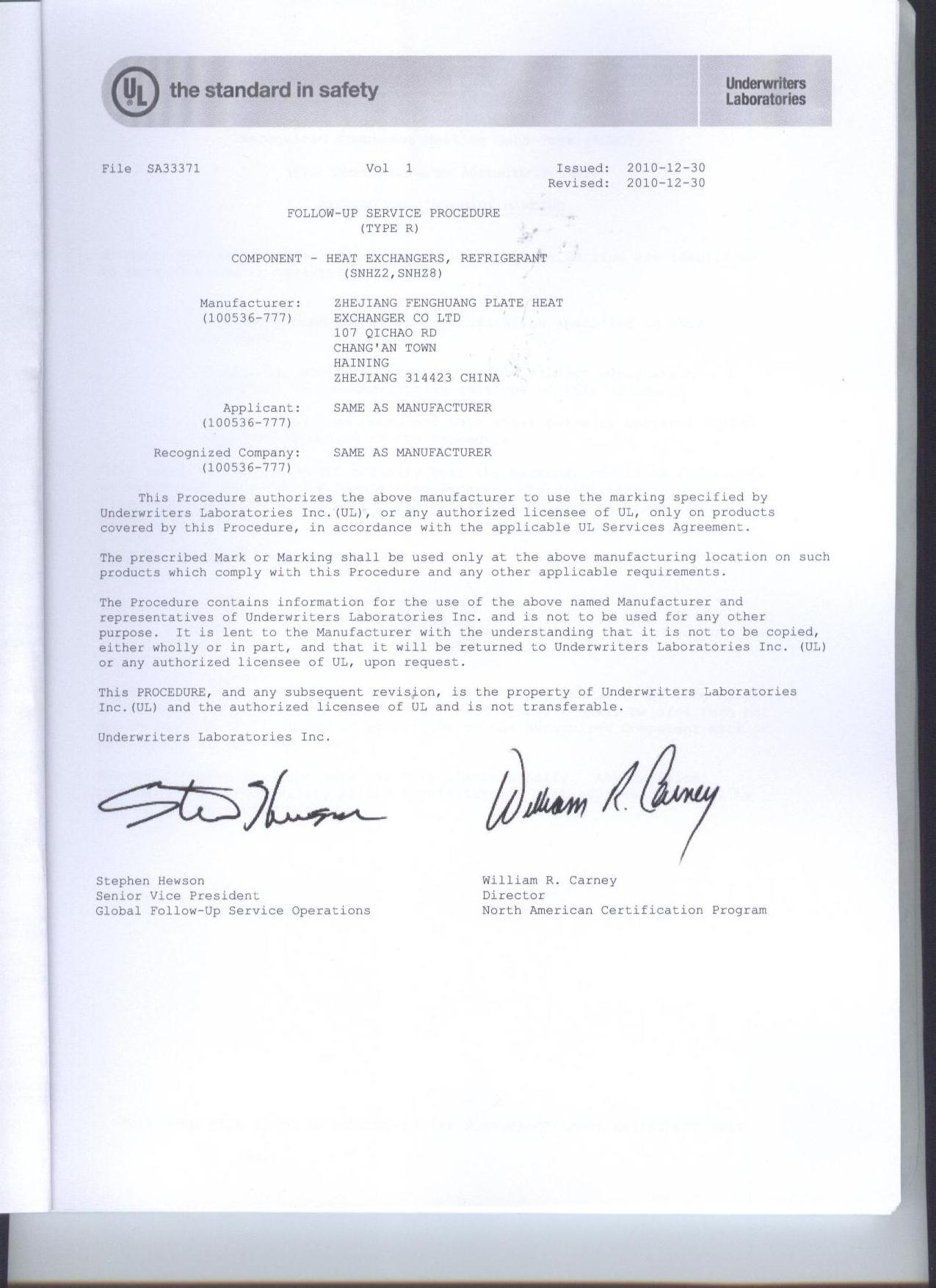

Certification:

-

CE, RoHS, ISO9001, ISO14001

-

Material:

-

SS316L, SS304

-

Brazing material:

-

99.9% Copper

-

Application:

-

HVAC, chiller, etc

-

Available connections:

-

Solder, thread, flanges, etc

-

Marketing Type:

-

New Product 2021

Quick Details

-

Structure:

-

Plate Heat Exchanger

-

Voltage:

-

220V

-

Core Components:

-

OTHER

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Forwon

-

Liquid Flow Rate:

-

4m3/h

-

Maximum Working Pressure:

-

67.5bar

-

Weight:

-

1 KG

-

Dimension(L*W*H):

-

192*73mm

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

None

-

Certification:

-

CE, RoHS, ISO9001, ISO14001

-

Material:

-

SS316L, SS304

-

Brazing material:

-

99.9% Copper

-

Application:

-

HVAC, chiller, etc

-

Available connections:

-

Solder, thread, flanges, etc

-

Marketing Type:

-

New Product 2021

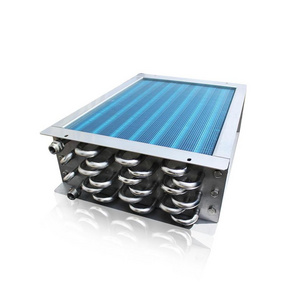

Fhc012 Air Air Heat Blower Water Cool Heat Exchanger

1.Compact structure: adopt thin stainless steel, high heat transfer factors.

2.Reliability: adopt 316L and copper as well as high quality brazing works. Endure high pressure and temperature. Long life and no

maintenance need.

3.Reduce water require: with the high heat transfer efficiency, only needs 1/3 water usage compare to shell and tube exchanger

under same condition

4.Lightly: Only 20-30% weight compare to shell and tube heat exchanger and reduce the logistics cost.

5.Low fouling factors: high disorderly flow lower the fouling condition, reduce the maintain.

6.With distributor: increase the refrigerant evaporating efficiency and reduce the risks by using distributor to force the

refrigerant flow direction.

2.Reliability: adopt 316L and copper as well as high quality brazing works. Endure high pressure and temperature. Long life and no

maintenance need.

3.Reduce water require: with the high heat transfer efficiency, only needs 1/3 water usage compare to shell and tube exchanger

under same condition

4.Lightly: Only 20-30% weight compare to shell and tube heat exchanger and reduce the logistics cost.

5.Low fouling factors: high disorderly flow lower the fouling condition, reduce the maintain.

6.With distributor: increase the refrigerant evaporating efficiency and reduce the risks by using distributor to force the

refrigerant flow direction.

Hot Searches