- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

BH-Roving

-

Tex Count:

-

1200-4800tex

-

Product:

-

Roving Fibers

-

Application:

-

FRP PRODUCTS

-

Glass type:

-

E-Glass

-

Color:

-

White

-

Process:

-

Centrifugal Casting

-

Product Name:

-

Fiberglass Assembled Roving for Centrifugal Casting

-

Raw material:

-

Glass Yarn

-

Package:

-

Carton / Cardbox

-

Compatible resin:

-

UP/VE/EP/PF

-

Keywords:

-

Assembled roving

Quick Details

-

Type:

-

E-glass

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

XINGLI BEIHAI

-

Model Number:

-

BH-Roving

-

Tex Count:

-

1200-4800tex

-

Product:

-

Roving Fibers

-

Application:

-

FRP PRODUCTS

-

Glass type:

-

E-Glass

-

Color:

-

White

-

Process:

-

Centrifugal Casting

-

Product Name:

-

Fiberglass Assembled Roving for Centrifugal Casting

-

Raw material:

-

Glass Yarn

-

Package:

-

Carton / Cardbox

-

Compatible resin:

-

UP/VE/EP/PF

-

Keywords:

-

Assembled roving

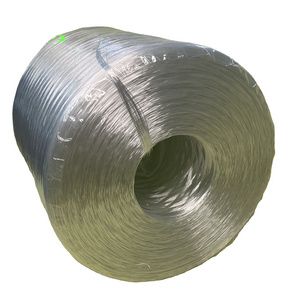

Products Description

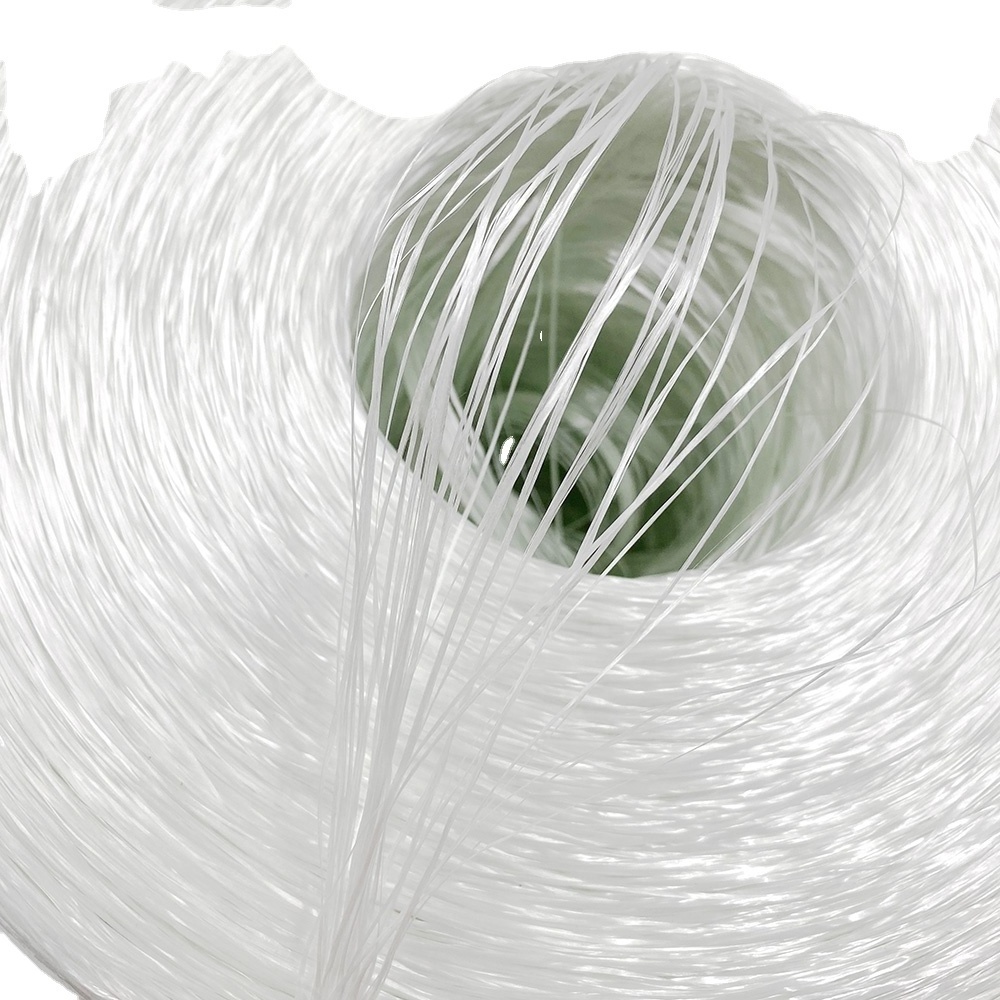

Fiberglass Roving Assembled Continuous Smc Roving Fiber Glass

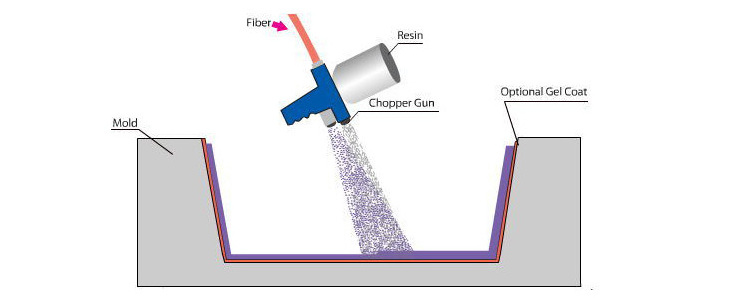

Assembled Roving for spray-up

Twistless roving for alkali-free jetting is mainly suitable for reinforcing unsaturated polyester (UP), vinyl resin (VE) and polyurethane resin (PU). It has good dispersibility and low static electricity, good resin impregnation and good compatibility with resins.

In production, since continuous cutting is required, it is necessary to ensure that less static electricity is generated during cutting, which requires good cutability. After cutting, it is ensured that as many raw yarns are produced as possible, so the efficiency of yarn formation is ensured to be high. Untwisted roving has a high efficiency of dispersing into raw yarn after cutting. After cutting, it is necessary to ensure that the raw yarn can be fully covered by the mold, so the raw yarn must have good coating properties. The resin is required to soak in very quickly because it is easy to be rolled flat to remove air bubbles. Since there are different types of spray guns, it is necessary to make sure that the thickness of the raw wire is appropriate for each type of spray gun.

Product Paramenters

|

Item

|

Linear Density

|

Resin Compatibility

|

Features

|

End Use

|

|

BHSU-01A

|

2400,4800

|

UP,VE

|

fast wet out, easy roll-out, optimum dispersion

|

bathtub, supporting components

|

|

BHSU-02A

|

2400,4800

|

UP,VE

|

easy roll-out, no spring-back

|

bathroom equipment, yacht components

|

|

BHSU-03A

|

2400,4800

|

UP,VE,PU

|

fast wet out, excellent mechanical and water resistance property

|

bathtub, FRP boat hull

|

|

BHSU-04A

|

2400,4800

|

UP,VE

|

moderate wet out speed

|

swimming pool, bathtub

|

Product Feature

1. Good cutability, less static electricity generated during continuous high speed cutting;

2. high efficiency in dispersing the untwisted roving into raw silk after cutting, i.e. high bunching rate, usually more than 90% is required;

3. The short-cut raw silk has excellent mold-covering property, which can be covered in all corners of the mold;

4. fast resin penetration, easy to be rolled flat and easy to drive away air bubbles;

5. The raw filament tube has good annealing performance and uniform roving density, which is suitable for all kinds of spray guns and fiber delivery systems. No-twist roving for spraying is made of multi-stranded filament winding, each strand of filament contains 200 glass fiber monofilaments.

Application

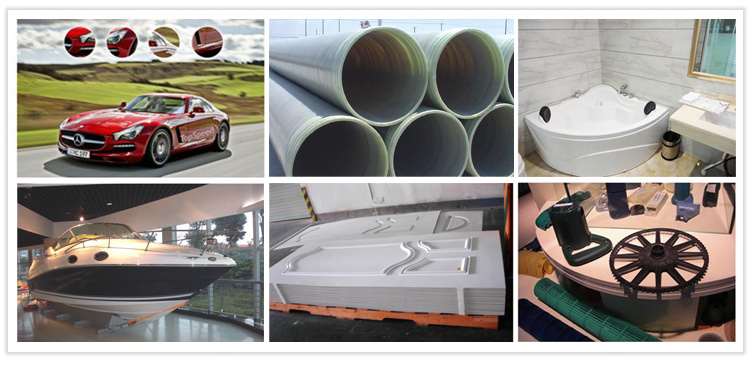

1. Construction field: bathtubs, fiberglass hulls, etc.

2. Infrastructure field: various pipes, storage tanks, cooling towers, etc.

3. Automobile field: various automobile parts, etc.

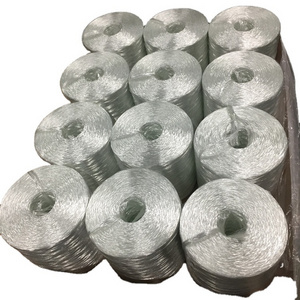

Product packaging

Hot Searches