- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

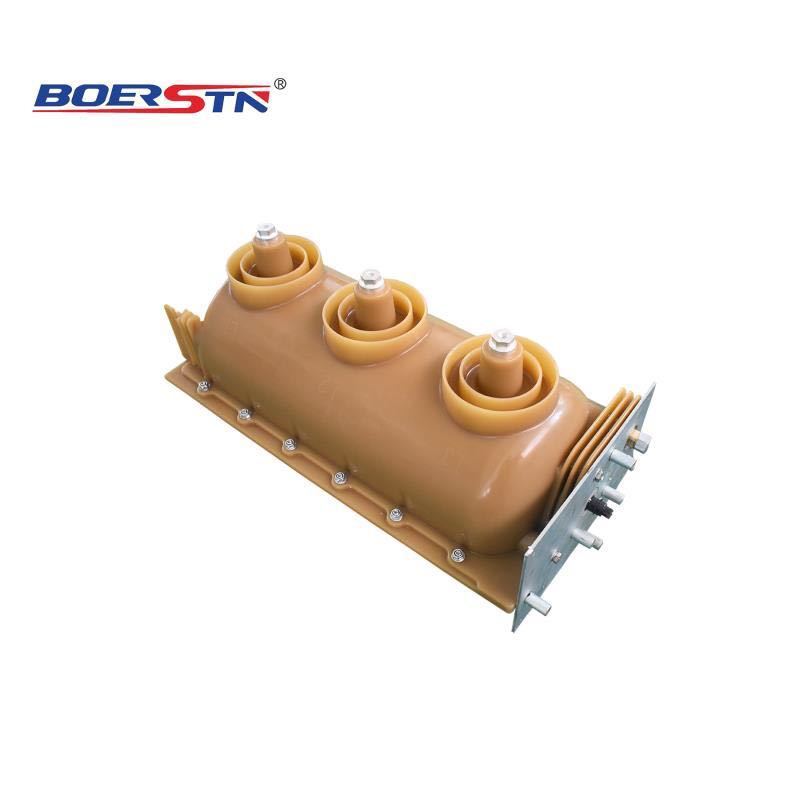

Boerstn

-

Model Number:

-

BRFLN36

-

Type:

-

Indoor Type

-

Name:

-

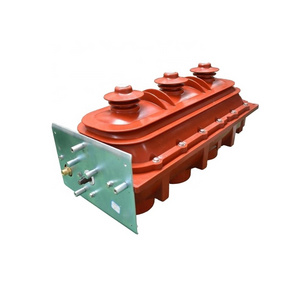

Indoor Load Break Switch 12kV 24kV

-

Material:

-

Epoxy Resin

-

Standard:

-

IEC

-

Certificate:

-

ISO9001

-

OEM:

-

Yes

-

Color:

-

YELLOW

Quick Details

-

Voltage:

-

12

-

Current:

-

630

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Boerstn

-

Model Number:

-

BRFLN36

-

Type:

-

Indoor Type

-

Name:

-

Indoor Load Break Switch 12kV 24kV

-

Material:

-

Epoxy Resin

-

Standard:

-

IEC

-

Certificate:

-

ISO9001

-

OEM:

-

Yes

-

Color:

-

YELLOW

BRFLN36-12/24 an indoor high-voltage SF6 load switch, an switchgear with the rated voltage of 12KV/24kV, adopted with SF6 gas as an arc-extinguishing and insulation medium, including the three contactors for switching-on and switching-off and to-ground, and is characteristic in its small volume, its convenient installation and operation and its the great adaptability with surroundings.

BRFLN36-24 of an indoor high-voltage SF6 load switch and BRFLN36-24D of SF6 load switch plus fuse combination can function to protect and control the electric equipments for power supply and transformer substations especially being suitable for ring net cabinet, cable branch cabinet and distribution switching substation.

BRFLN36-24 of an indoor high-voltage SF6 load switch and BRFLN36-24D load switch plus fuse combination are complied with the standards of IEC60265-1-1998, IEC60420 etc.

Service Environment

a) Air temperature

Maximum temperature: +40℃; Minimum temperature:-35℃

b) Humidity

Monthly average humidity 95%; Daily average humidity 90% .

c) Altitude above sea level

Maximum installation altitude: 2500m

d) Ambient air not apparently polluted by corrosive and flammable gas, vapor etc.

e) No frequent violent shake.

Main Specification & Technical Data

12kV Parameters:

|

No. |

Technical Name |

Unit |

Model |

|||

|

|

|

|

BRFLN36-12/630 |

BRFLN36-12D/125-50 switch-fuse combinations |

||

|

1 |

Rated voltage |

KV |

11 |

|||

|

2 |

Rated Frequency |

Hz |

50/60 |

|||

|

3 |

Rated current |

Amp |

630 |

125 |

||

|

4 |

Rated Insulation Level |

L min power-frequency withstand voltage (KV) |

42 |

48 |

||

|

|

|

Lighting impulse withstand voltage (Peak) KV |

75 |

85 |

||

|

5 |

Rated thermal current (2S) |

KA |

20 |

|

||

|

6 |

Rated dynamic current |

KA |

50 |

|

||

|

7 |

Rated short-circuit on-off current |

KA |

25 |

|

||

|

8 |

Rated closed loop breaking current |

A |

630 |

|

||

|

9 |

A |

630 |

|

|||

|

10 |

Rated cable charger breaking current |

A |

10 |

|

||

|

11 |

Rated short-circuit breaking current(peak) |

KA |

|

50 |

||

|

12 |

A |

|

1700 |

|||

|

13 |

Fuse type |

|

|

Sfldj-12 |

||

|

14 |

Impact output energy |

J |

|

1+0.5 |

||

|

15 |

Rated thermal current(2S)for grounding switch |

KA |

20 |

2 |

||

|

16 |

Rated dynamic current (peak)for grounding switch |

KA |

50 |

Maximum torque operated manually |

||

|

17 |

Rated short-circuit on-off current for grounding switch |

KA |

50 |

|

||

|

18 |

Mechanical life |

Load switch |

times |

5000 |

||

|

|

|

Grounding switch |

times |

2000 |

||

|

19 |

(Zero gauge pressure)on-off rated current times |

times |

10 |

10 |

||

|

20 |

The air distance to the earth and distance between electrified body |

mm |

More than 125 mm |

|||

|

21 |

SF6 Air Pressure (20 relative pressure) |

Bars |

0.45 |

0.45 |

||

|

22 |

Synchronism of switching on and off |

ms |

2 |

2 |

||

|

23 |

Loop resistance |

U |

100 |

100 |

||

|

24 |

Max. torque operated manually |

NM |

Less than 75 |

|||

|

25 |

Operated motor rated voltage |

V |

AC / DC 110V 220V |

|||

|

26 |

On-off electric –magnetic steel operation voltage |

V |

AC / DC 110V 220V |

|||

24kV Parameters:

|

No |

Item |

Unit |

Parameter |

|

|

1 |

Rated voltage |

kV |

24 |

|

|

2 |

Rated frequency |

Hz |

50/60 |

|

|

3 |

Rated current |

A |

630/800 |

|

|

4 |

1min Power frequency withstand voltage |

wet |

kV |

65 |

|

|

|

dry |

kV |

75 |

|

5 |

Lightning impulse withstand voltage |

kV |

125/150 |

|

|

6 |

Rated short circuit breaking current (peak) |

kA |

63 |

|

|

7 |

Rated active load and close circuit breaking current |

A |

50 |

|

|

8 |

Rated transferring current |

A |

1000 |

|

|

9 |

Rated short circuit making current (peak) |

kA |

63 |

|

|

10 |

Rated cable(line) charging breaking current |

A |

50 and 10 |

|

|

11 |

Cable charge breaking current in earthing fault |

A |

20 |

|

|

12 |

Rated withstand current (peak) |

kA |

63 |

|

|

13 |

Short time withstand current (2s) |

kA |

25 |

|

|

14 |

Mechanism life |

times |

2000 |

|

Outline Dimension

Side View BRFLN36-12D Type SF6 Load Break Switch (LBS)

Front View Load Break Switch

Block Diagram for BRFLN36-12D type SF6 Load Break Switch

Structure & Principle

On position Off Position Grounding Position

The main loop structure for load break switch

BRFLN36-12D type indoor SF6 load break switch & its composite apparatus, its main loop partially is sealed in an insulating shell made of epoxy resin. This insulation shell adopts APG process injection, which has advantages of high insulation and antipollution environment etc. The insulation shell is its upper & lower 2 insulation cover pieced together. Inside there has relative pressure 0.45bars SF6 gas. Its lower insulation cover takes some anti-explosion thicker film measures to avoid the high pressure gas release explosion in case of failure to prevent the operator and other parts.

BRFLN36-12D type indoor high voltage SF6 load break switch and its combination electrical has on, off and grounding 3 positions.

Arc extinguishing principle

BRFLN36-12D type load break switch take its inside SF6 gas as insulation & arc extinguishing medium. When it switches off, the arc goes to rotate under the magnetic field produced by permanent magnet, then cools under the SF6 gas till it is extinguished.

Operating Structure & inter-lock

For BRFLN36-12D type indoor high voltage SF6 load break switch & its composite apparatus, its operating structure is with K type & A type spring institutions. If equipped with K type spring institution, it is mainly used for incoming unit. If equipped with A spring institution, it is mainly used for outgoing unit and transformer protection.

Attention: Only when this SF6 LBS in off position, its switch-on or grounding work can be operated !

Installation,Maintenance

a)Installation & testing

All BRFLN36-12(D)type LBS are strictly inspected before off the Boerstn factory, which comply with the standard and technical requirements. Before the installation & testing, must carefully read the installation & usage instructions, and work as following:

1. Check if the appearance is damaged. If so ,should stop the usage

2. Clear and get rid of the dirt on its face because of transport of other reasons

3. After installation well ,must be sure that the load switch in off position. If so, insert the operation handle into the grounding holes on its upper board ,then rotate clockwise 180 to switch on the grounding. Anti-clockwise 180 to off the grounding.

4. When go to do the work of switching –on, firstly let the load switch be off position, then insert the operation handle into the operating hole of the load switch in lower board

5. Operating From switch-on to switch off,

For K type spring institution : insert the operation handle into the hole of load switch, anti-clockwise rotate 180 to do the off-switch.

For A type spring institution, push the switch-off button to off the switch.

Inspect the switch position through its viewing window, and watch its indication comply with the requirements or not.

Attention: Only when the switch in off position, can go to switch on the grounding or load.

Maintenance

If the product is in accordance with the requirements of the installation instructions & environment ,it can be in 10 years free maintenance and can reliable work for 25 years. But per each year ,must do the necessary inspection and maintenance.

1. Inspect the appearance of its insulation cover, get rid of its dirt on face.

2. Conduct 3-5 lubrication and operation checks on the operating mechanism

3. Check the readings of the pressure gauge on load switch. When readings is lower than 0.01Mpa, it should be filled gas in time. The work of filling gas should be done by professional work or from the factory.

4. When load break switch + fuse composite apparatus is damaged ,one phase fuse blow, then must replace all 3 phase fuses. Before replacement, must switch on the grounding switch.