- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

Daegu, South Korea

-

Brand Name:

-

DAEWOO ENG

-

Model Number:

-

HEATING FILM

-

Heating system:

-

Film

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Other

-

Project Solution Capability:

-

Others

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

Daegu, South Korea

-

Brand Name:

-

DAEWOO ENG

-

Model Number:

-

HEATING FILM

-

Heating system:

-

Film

Products Description

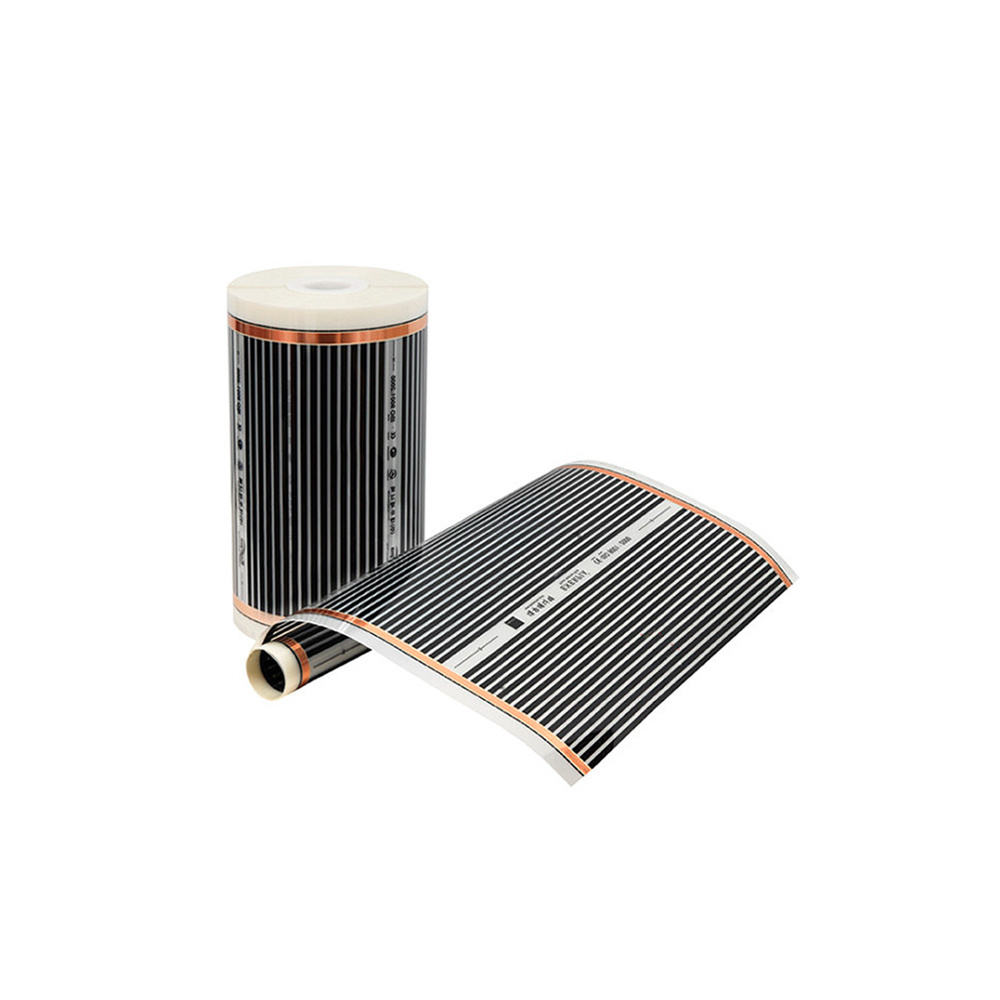

Far Infrared Rays Floor Heating Film

WHAT IS DAEWOO HEATING FILM?

It is an innovative heating system that is made with gravure printing of heat generating carbon tissue on PET Film and copper busbar. Since it emits far infrared rays and anions, warm radiant heat can be felt for a well-being life.

This film is ideal for during the certain time for the sectional space that needs to be heated because it requires a short period of time to make heat so suitable for customer, accommodation, office, church, restaurant, and stairs. For stable use, we recommend you to use the hardwood as the finishing material. If you are using for the linoleum finishing or humid environment, you need to

consult with a construction company.

This film is ideal for during the certain time for the sectional space that needs to be heated because it requires a short period of time to make heat so suitable for customer, accommodation, office, church, restaurant, and stairs. For stable use, we recommend you to use the hardwood as the finishing material. If you are using for the linoleum finishing or humid environment, you need to

consult with a construction company.

1. Feature of Heating film

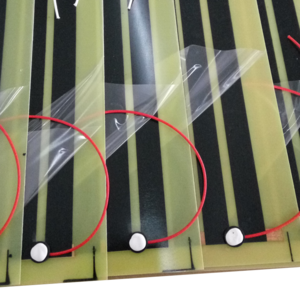

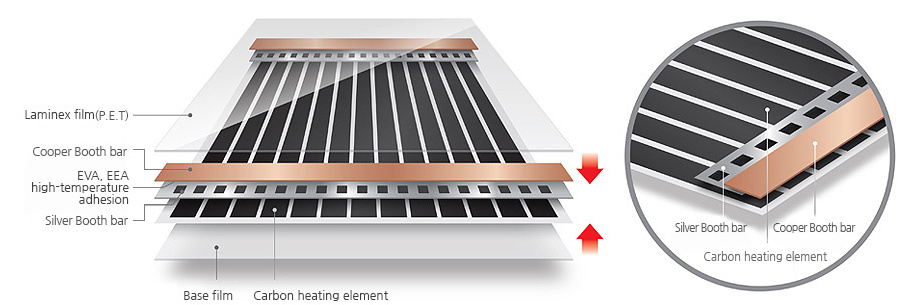

1. Burning resist PET application : The ivory PET Film is used the XB-65 with VTH-2 chip in for heat defying insulation which has the UL Certificate and is manufactured by Doraysaeghan.

2. Gravure printing : As screen printing cannot print carbon tissue evenly, it is inappropriate for the heat generating plate. It can be partially overheated to cause fire and short circuit. We, however, have chosen the gravure rotary printing press to pursue to the safety by giving electric resistance evenly to the Heat Generating Plate.

3. Wide silver space : The silver space is for the space between carbon and copper busbar where the electrical energy is converted to thermal energy. This space prevent spark, and is important part related to product life and safety. We broadened this space for safety.

4. Copper busbar with 12mm of width and 10amp : Wide copper busbar to restrain overheating.

The thinner PET has superior adhesive strength and keeps air cut.

2. Gravure printing : As screen printing cannot print carbon tissue evenly, it is inappropriate for the heat generating plate. It can be partially overheated to cause fire and short circuit. We, however, have chosen the gravure rotary printing press to pursue to the safety by giving electric resistance evenly to the Heat Generating Plate.

3. Wide silver space : The silver space is for the space between carbon and copper busbar where the electrical energy is converted to thermal energy. This space prevent spark, and is important part related to product life and safety. We broadened this space for safety.

4. Copper busbar with 12mm of width and 10amp : Wide copper busbar to restrain overheating.

The thinner PET has superior adhesive strength and keeps air cut.

2.Benefits Heating film

1) Energy can be saved more than 65%.(On regular basis)

2) No need space for boiler

3) Far infrared radiation (90.3%) and anions (250cc) are emitted to improve health.

4) Don’t worry about smoke, noise, fueling, freezing.

5) Convinient control such as sectional heating, central heating and sectional control.

6) One day installation and immediately usable

7) Free to choose of finishing materials

8) Fast installation without taking off the existing floor

9) It can lower the height of ceiling and the weight of building.

1) Energy can be saved more than 65%.(On regular basis)

2) No need space for boiler

3) Far infrared radiation (90.3%) and anions (250cc) are emitted to improve health.

4) Don’t worry about smoke, noise, fueling, freezing.

5) Convinient control such as sectional heating, central heating and sectional control.

6) One day installation and immediately usable

7) Free to choose of finishing materials

8) Fast installation without taking off the existing floor

9) It can lower the height of ceiling and the weight of building.

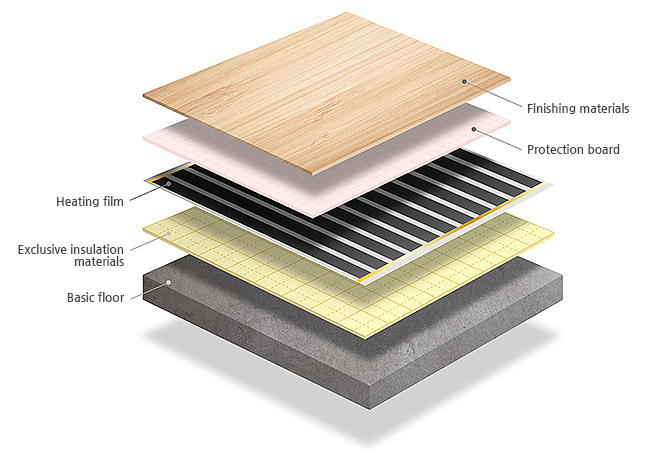

3.Structure of Far-infrared ray heating film

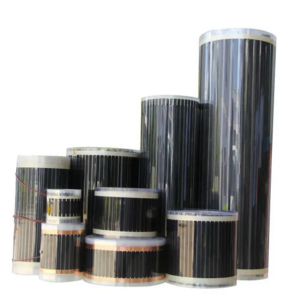

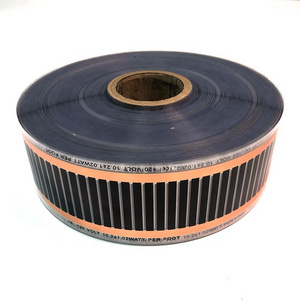

4. Specifications of Far-infrared ray heating film

|

Model No

|

Power(W) 220v

|

Product specification

|

|

EP-305

|

110 W/m

|

0.338T 50cm X 150m

|

|

EP-308

|

170 W/m

|

0.338T 80cm X 100m

|

|

EP-310

|

220 W/m

|

0.338T 100cm X 100m

|

|

EP-305(T)

|

customized

|

0.338T 50cm X 150m

|

|

EP-308(T)

|

customized

|

0.338T 80cm X 100m

|

|

EP-310(T)

|

customized

|

0.338T 100cm X 100m

|

|

EP-410

|

220 W/m

|

0.380T 100cm X 75m

|

Product specification (length), electricity consumption, and heating area can be customized

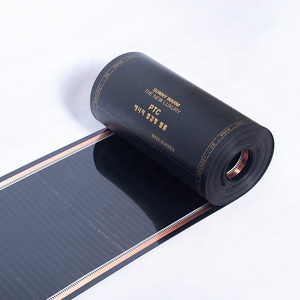

Far-infrared ray PTC heating film

When normal film do not show changes in power consumption rate as temperature rises, Heating Film with PTC characteristic shows about 23% decrease in power consumption when the film’s surface temperature reaches from 10℃ to 60℃. Heating Film(PTC) is printed with carbon paste which has superb electric characteristic, eliminating partial overheating. Such superb characteristic saves energy and promotes product safety.

5. Specifications of Far-infrared ray PTC heating film

|

Model No

|

Power (W) 220v

|

Product specification

|

|

EP-PTC-305(T)

|

customized

|

0.338T 50cm X 150m

|

|

EP-PTC-308(T)

|

customized

|

0.338T 80cm X 100m

|

|

EP-PTC-310(T)

|

customized

|

0.338T 100cm X 100m

|

|

EP-PTC-305

|

customized

|

0.338T 50cm X 150m

|

|

EP-PTC-308

|

customized

|

0.338T 80cm X 100m

|

|

EP-PTC-310

|

customized

|

0.338T 100cm X 100m

|

|

EP-PTC-410

|

customized

|

0.380T 100cm X 75m

|

|

EP-PTC-3805

|

customized

|

0.380T 100cm X 100m

|

|

EP-PTC-3808

|

customized

|

0.380T 100cm X 100m

|

|

EP-PTC-3810

|

customized

|

0.380T 100cm X 100m

|

Product specification (length), electricity consumption, and heating area can be customized

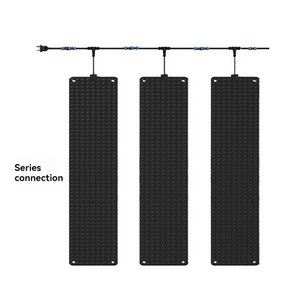

6. Construction cross-section

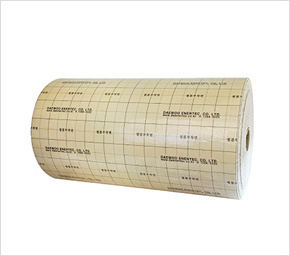

7. Subsidiary materials

Insulating materials for heating film

Compression terminal

Compressor

Butyl tape

8. Construction procedure

1. Design blueprint

2. Install insulating materials for heating film

3. Install far-infrared heating film

4. Connect compression terminal

5. Connect wire

6. Conduct insulation work

7. Performance test

8. Install protection board

9. Install finishing materials

Caution

Because film heating is a dry method, cement mortar finishing (wet method) may cause defect.

Use compression protective board when applying tecotile or monoleum.

Use compression protective board when applying tecotile or monoleum.

Specification

|

Category

|

Description

|

|

Warranty

|

1 Year

|

|

After-sale Service

|

Other

|

|

Material

|

Other

|

|

Project Solution Capability

|

Others

|

|

Application

|

Hotel

|

|

Design Style

|

Modern

|

|

Place of Origin

|

South Korea Daegu

|

|

Brand Name

|

DAEWOO ENG

|

|

Model Number

|

HEATING FILM

|

|

Type

|

Floor Heating Parts, Floor Heating Films

|

|

Heating system

|

Film

|

Hot Searches