- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

3824500000

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Biaoyuan

-

Model Number:

-

BY701

-

Type:

-

One Component

Quick Details

-

CAS No.:

-

3824500000

-

Other Names:

-

Flexible Tile adhesive

-

MF:

-

Mixture

-

EINECS No.:

-

3824500000

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Biaoyuan

-

Model Number:

-

BY701

-

Type:

-

One Component

concrete tile joint adhesive sealant/ glue

Introduction:

BiaoYuan Tile Adhesive is a specially formulated cement-based adhesive for fixing ceramic floor and wall tiles on internal and external floors and walls.

It is used to fix porcelain tiles, marbles, natural granites, natural stones, travertine,pool tiles and pieces, and non-slip tiles of middle sized (up to 60x60cm size for the wall and any size for the floor).

Feature:

1 This product is polymer modified cement tile adhesive, and the performance is better than general cement mortar.

2 Sliding-resistance / dispense with soaking bricks/ thin construction layers /high stickiness/no hollowness/ environment friendly/water-fast well.

3:Grey colors, For different specifications of the tiles.

4:Flexible Adhesive is a cement based flexible and rapid setting adhesive suitable for floor and wall tiling of natural stone, porcelain, ceramics and mosaics.

Application:

1) Suitable for interior and exterior use.

2) Suitable for substrate made from concrete, masonry, pre-cast material and lightweight brick.

3) Suitable for walls,floors and roofs of architects, such as tunnels, bridges, basement, kitchen, bathroom, balcony, swimming pool and reservoir and so on.

4) Suitable for architects with structure which might easily vibrate and split, such as post-cast strip, pipe orifice.

Technical Date:

|

Surface drying time(Hr) |

≤5 |

|

|

Cohesive strength |

standard state (Mpa) |

≥0.6 |

|

Freeze-thaw cycle (Mpa) |

≥0.4 |

|

|

Alkali resistance (48hr) |

No change |

|

|

Water resistance (96hr) |

No change |

|

|

Using level (kg/ m²) |

1-1.5 |

|

|

color |

White and g rey |

|

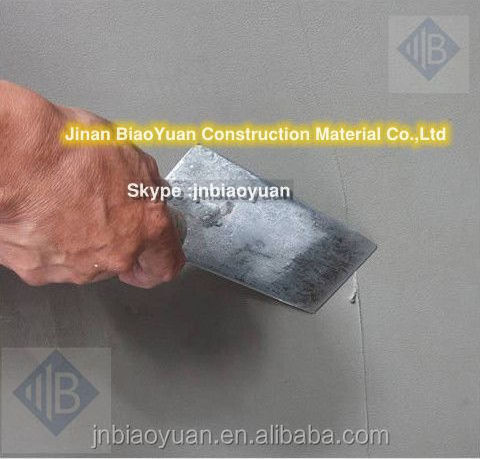

Step Methods:

A: Primary treatment

Primary surface should be smooth solid, and fully dry, no sand, crack, bump inequality defects; no dust traces of oil and dirt. So, when the surface is rough or raised, application of trowels to its eradication, in order to deal with smooth surface.

B:Open the packing bags :

Cleaning benefits to cut off the dust, keep clean, open the package, with electric blender into uniform, no powder paste, mortar to be standing ten minutes after stirring once again increases the strength. The note, with the shovel to leave no droplet pulp scraping ideal condition.

C:Large area construction:

With a brush dipped in water, swipe the back of the tile, then wipe with a toothed blade to about one cubic meter of powder, then rub the pressure on the tile can be.

Picture:

Shipping Picture:

Business Card: