- Product Details

- {{item.text}}

Quick Details

-

transformation type:

-

wheat/maize/rice

-

extraction:

-

70-80%

-

style:

-

pneumatic or electric

-

Project:

-

design,manufacture and install machines

-

Machinery:

-

roller mill,plansifter,dampener

-

System:

-

PLC controlling system

-

Color:

-

white , bule

-

Design:

-

advanced milling technology and CAD support

-

Certification:

-

ISO 9001

Quick Details

-

Place of Origin:

-

Hebei, China

-

After-sales Service Provided:

-

Field installation, commissioning and training, Engineers available to service machinery overseas

-

quality:

-

european standard

-

transformation type:

-

wheat/maize/rice

-

extraction:

-

70-80%

-

style:

-

pneumatic or electric

-

Project:

-

design,manufacture and install machines

-

Machinery:

-

roller mill,plansifter,dampener

-

System:

-

PLC controlling system

-

Color:

-

white , bule

-

Design:

-

advanced milling technology and CAD support

-

Certification:

-

ISO 9001

flour mill machine corn/maize/wheat roller mill

|

Equipment Name |

Complete Set flour mill,flour milling machine, corn flour mill |

|

Output |

40-2400T/24Hrs |

|

Main Cleaning Equipment |

1).High-efficiency Virbration Sieve |

|

2).De-stoner |

|

|

3).Corn Scourer |

|

|

4)Magnetic Separator |

|

|

5) computer control dampener |

|

|

Milling Equipment |

1) electrical Roller Mill |

|

2)Plansifter |

|

|

3)Purifier |

|

|

4)High Pressure Blower |

|

|

5)Impact Detacher |

|

|

Flour extraction rate(%) |

Grade 1 flour:72%-75%, |

|

Grade 2 flour:73%-78% |

|

|

Design is with flour blending system. it is to satisfy customer's request on types of special purpose flour including bread flour, cake flour ,biscuit flour, noodle flour etc. |

|

|

Size of workshop |

steel structure & multi-story cement building |

|

Spare part |

one year complete set spare parts for free |

|

Advantage |

1. With advanced technical process and flexible adjustment |

|

2.Adopt various configuration modes for different choices. There arestreamlined design, reasonable layout, and beautiful performance. |

|

|

3. Electrical parts are all famous international brand : SIEMENS, OMRON etc. |

|

|

4. Full automatic. |

The process of flour milling plant/machine (from wheat to milled into wheat flour)

usually consist of the following:

1. wheat storage (silos, or warehouse) ----------

2. cleaning system (sifter, destoner, seprater, magnet, scourer, etc) -----------

3. dampening (dampener, conditioning silos, etc) ----------

4. milling system (roller mill, plansifter, purifier, impact detacher, etc.) ----------

5. Flour pressure and blending system (if need) ----------

6. flour packing and stacking.

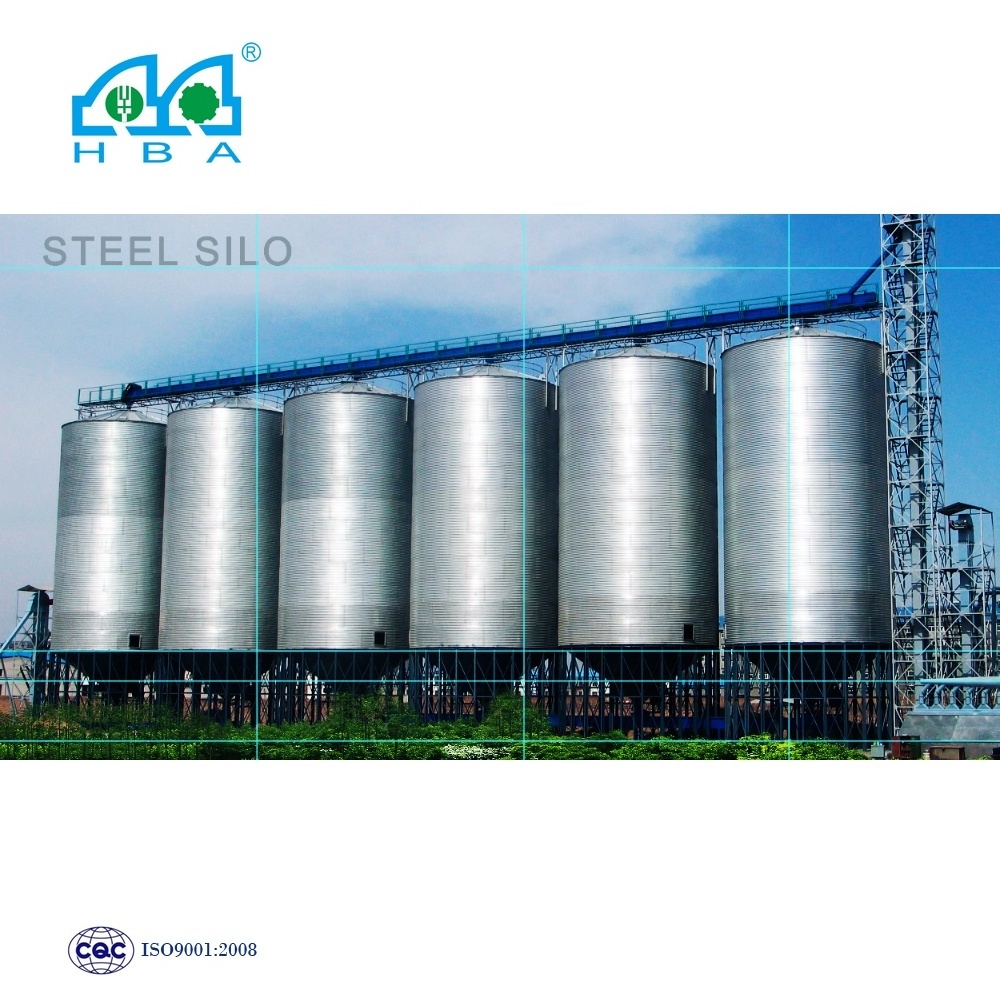

SILOS

We store wheat in silos. There are temperature detectors inside of silos. If the temperature

inside is very high, the blower can blow air into silos to reduce the temperature to protect

the grains.We have professional engineer guide and design.

ROLLER MILL

Depending on a pair of grinding rollers,which have different peeds and rotate oppositely,

wheat endosperm is peeled from bran coat and rolled into flour via squeezing,cutting ,pee

ling and scraping.

PLANSIFTER

Plansifter is mainly used for grading and inspecting of stocks from various systerms in

flour grinding.

INTENSIVE DAMPENER

Dampener is a moisture adjusting equipment in wheat cleaning process.For the automatic dampening control system,micro processor controls the water content according to preset conditioning moisture and keeps it at the optimal status constantly.

WHEAT SCOURER

Dampener Through impact and friction effects,wheat scourer cleans the adhesive impurities on wheat surface,removes wheat hair and bran and breaks the same size impurities of low hardness.

Fog Dampener

and bran and break It is mainly used for the second dampening before milling;it can add water finely and evenly in a rationale way to increase bran toughness,reduce ash content,improve break release rate and flour quality effectively.

High Efficiency Vibrating Sieve

It removes big,medium and small sized impurities ;it can be used together with aspirator to remove light impurities.

The flour mills installed by HBA-CHINA

| Country | project name | Picture |

| Mexico | 200T/24h wheat flour mill | |

| Salvador |

150T/24h maize flour mill and 50t/24h rice flour mill

|

|

| Ecuador | 80T/24h wheat flour mill | |

| Ireland | 300T/24h wheat flour mill | |

| Egypt | 60T/24h wheat flour mill | |

| Tanzania |

2 production line 50T/24h maize flour mill |

1. In 1~5 months after start of production, we will arrange the related professionals

should assist and instruct the production and operation at the site.

2. The warranty period is 12 months after the date of acceptance.

3. In the warranty period, when receiving the notification (telephone) for service sup

ply requested by the buyer, we will reply within 4 hours, and meanwhile assign expe

rienc ed technicians to arrive at the site within one week to provide service for the

buyer.