- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Chenlil

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

20000 kg

-

Mixer type:

-

Twin shaft or planetary mixer

-

Mixer discharge capacity:

-

1000-5000L

-

Maximum aggregate size:

-

80mm

-

Total Power:

-

152-420kw

-

Discharge height:

-

4.2m or Customized

-

Output:

-

60-300m3/h

-

Power type:

-

Electric

-

After warranty service:

-

spare parts or technical support

-

Working cycle:

-

60s

Quick Details

-

Machine Type:

-

Production line

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Chenlil

-

Power:

-

Chenlil

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

20000 kg

-

Mixer type:

-

Twin shaft or planetary mixer

-

Mixer discharge capacity:

-

1000-5000L

-

Maximum aggregate size:

-

80mm

-

Total Power:

-

152-420kw

-

Discharge height:

-

4.2m or Customized

-

Output:

-

60-300m3/h

-

Power type:

-

Electric

-

After warranty service:

-

spare parts or technical support

-

Working cycle:

-

60s

Concrete mixing station for manufacturing plant

Concrete batching plant

is a building material manufacturing equipment consisting of five major systems: mixing host, material weighing system, material conveying system, material storage system, control system and other ancillary facilities. The main working principle of the concrete batching station is to use cement as the cementing material to mix sand, gravel, lime, cinder and other raw materials together, and finally make into concrete, which is used in construction and production as a wall material. Generally speaking, concrete batching plants are divided into two categories: stationary concrete batching plants and mobile concrete batching plants.

1. Batching bin

1. Batching bin

2. Aggregate weighing scale

3. Flat belt conveyor

4. Inclined belt conveyor

5. Aggregate storage warehouse, mixing machine, powder weighing scale, water weighing scale are inside

6. Powder silo

7. Screw conveyor

8. Control room

9. Discharge port

Working principle

The aggregates in the aggregate bin of the concrete batching plant are discharged into the aggregate measuring hopper through the discharge port for measurement. After measurement, the aggregates are discharged onto the running flat belt and sent to the inclined belt conveyor. The inclined belt conveyor transports the aggregates to the aggregate storage warehouse on the up of the mixer to waiting for instructions. At the same time, cement and fly ash are transported to their respective metering hoppers by screw conveyors for weighing, and water and admixtures are sent to their respective metering hoppers for weighing by water pumps and admixture pumps respectively. After weighing, according to the instructions issued by the control system, various materials are put into the mixer in turn for mixing. After the mixing is completed, open the discharge port of the mixer, discharge the concrete into the mixing transport through the discharge hopper, and then enter the next working cycle.

1. High-end environmentally friendly concrete batching plant

2. Engineering box concrete batching plant

3. Standard commercial concrete batching plant

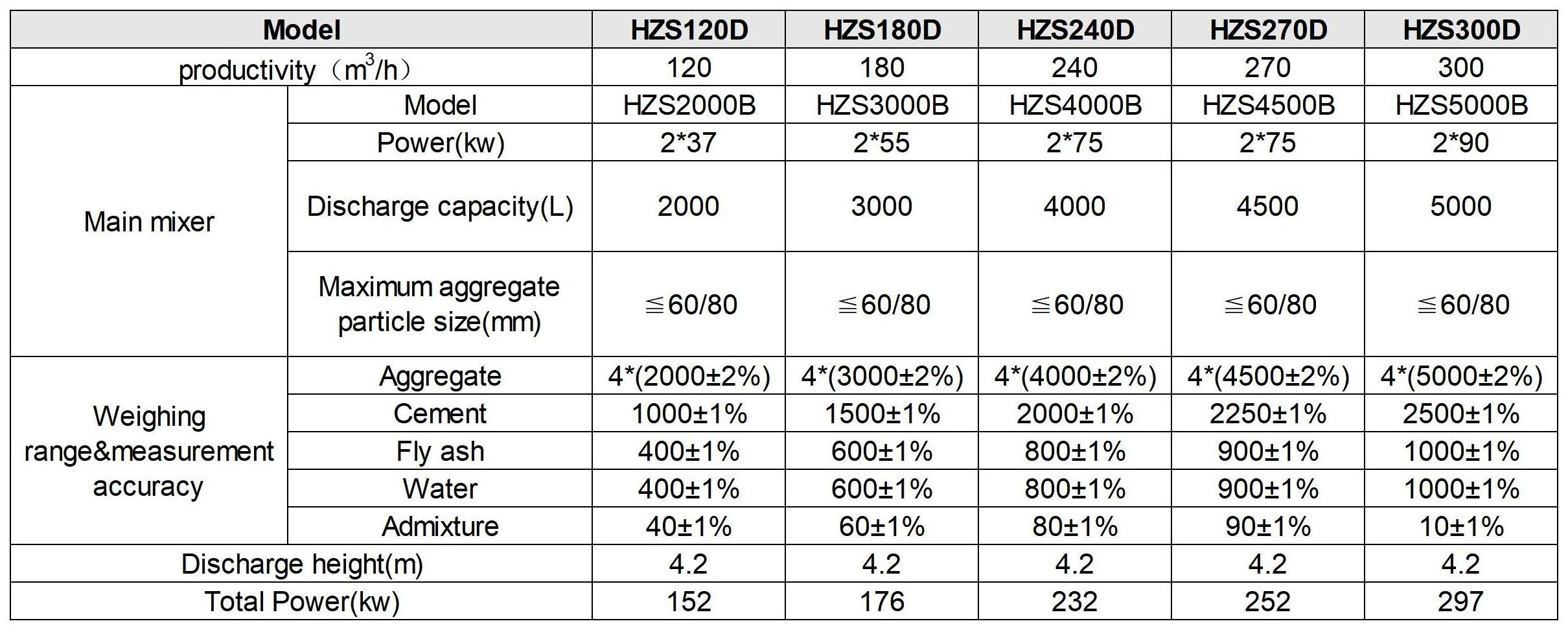

4. PC special concrete mixing station The parameters in the table are incomplete. Click here for more information.

Concrete mixing station is a combined device used to centrally mix concrete, also known as concrete precast yard. Due to the high degree of mechanization and automation of the concrete mixing station, the productivity is also very high, and it can ensure the quality of concrete and save cement. Concrete batching plant is often used in large and medium-sized engineering construction such as water conservancy, electric power, bridges, etc. which is large where the is large concrete project volume, long construction period, and concentrated construction site. With the development of municipal construction, batching plant that uses centralized mixing and provide commercial concrete have great advantages, so concrete batching plant has developed rapidly and created conditions for promoting concrete pumping construction and realizing the combined operation of mixing, conveying and pouring machinery.

High-end environmentally friendly concrete batching plant.

Conveyed by inclined belt conveyor, flexible site layout

The powder silo is on the top, with a majestic structure, small footprint and easy overall packaging.

concrete batching plant adopts air trough transportation, which has low energy consumption, maintenance-free, environmental protection and energy saving.

High-precision weighing and efficient mixing technology to maximize concrete quality.

Concrete batching plant is suitable for commercial concrete production and supply, large engineering project construction or medium and large concrete prefabricated plants.

Engineering container concrete batching plant

Modular design, easy disassembly and assembly, easy transportation, and flexible site layout.

The belt conveyor is used for loading, which has stable performance. It is equipped with an aggregate storage hopper and the concrete batching plant has high productivity.

High powder weighing accuracy and strong anti-interference ability.

Container-style exterior decoration, safe and convenient to disassemble and assemble, and can be reused.

The electrical system and pneumatic system are equipped with high-end configuration and high reliability.

Standard commercial concrete batching plant

Ground warehouse type aggregate configuration, stable performance and high safety.

The material is transported by inclined belt conveyor and the site layout is flexible.

Concrete batching plant adopts a large steel frame design and the overall appearance is majestic.

High-precision weighing and efficient mixing technology maximize concrete quality.

Container-style exterior decoration, safe and convenient to disassemble and assemble, and can be reused.

The electrical system and pneumatic system are equipped with high-end configuration and high reliability.

PC special concrete batching plant.

Vertical shaft planetary mixing host.

Higher precision measurement.

Perfect management system.

Precise temperature and humidity control.

Multiple discharge ports can be set up to supply multiple concrete product production lines at the same time.

Environmentally friendly design.

Tai'an Chenli Construction Machinery Co., Ltd. is a technology-based company focusing on the development, design, manufacturing, engineering and service of intelligent complete equipment for building materials. Based on a deep understanding of building intelligent equipment, Taian Chenli is committed to providing users with "practical, efficient, low-carbon, environmentally friendly, intelligent and advanced" intelligent equipment products. In line with the product concept of "excellence in quality, simplicity to the extreme", committed to the high-tech development and application of intelligent equipment, energy-saving and environmentally friendly equipment for new building materials. The current leading products are cement concrete batching plants, mortar production lines, tower type sand making machine, and environmental protection equipment for batching plants. The products win the trust of the market with high standards and high reliability, and are deeply trusted by users.

Click Here to Contact Us