- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Guangmao

-

Dimension(L*W*H):

-

670*820*760

-

Weight:

-

8000 KG

-

Installation:

-

Engineer Guide

-

Factory Visit:

-

Welcomed Warmly

Quick Details

-

Application:

-

mobile quarry crusher plant, Energy Mining

-

Capacity(t/h):

-

1-3

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

Guangmao

-

Dimension(L*W*H):

-

670*820*760

-

Weight:

-

8000 KG

-

Installation:

-

Engineer Guide

-

Factory Visit:

-

Welcomed Warmly

Product Description

Jaw crusher is a kind of stone crushing machine which is widely used as primary or secondary crusher.

It is widely used in various industries, such as mining, road and railway construction, building construction,water conservation and chemical industry etc. It could crush kinds of minerals and rocks with compression strength less than 320MPa,such as quartz, granite, basalt, limestone, river stone, sandstone, shale, iron ore, copper ore, gold ore etc.

product details

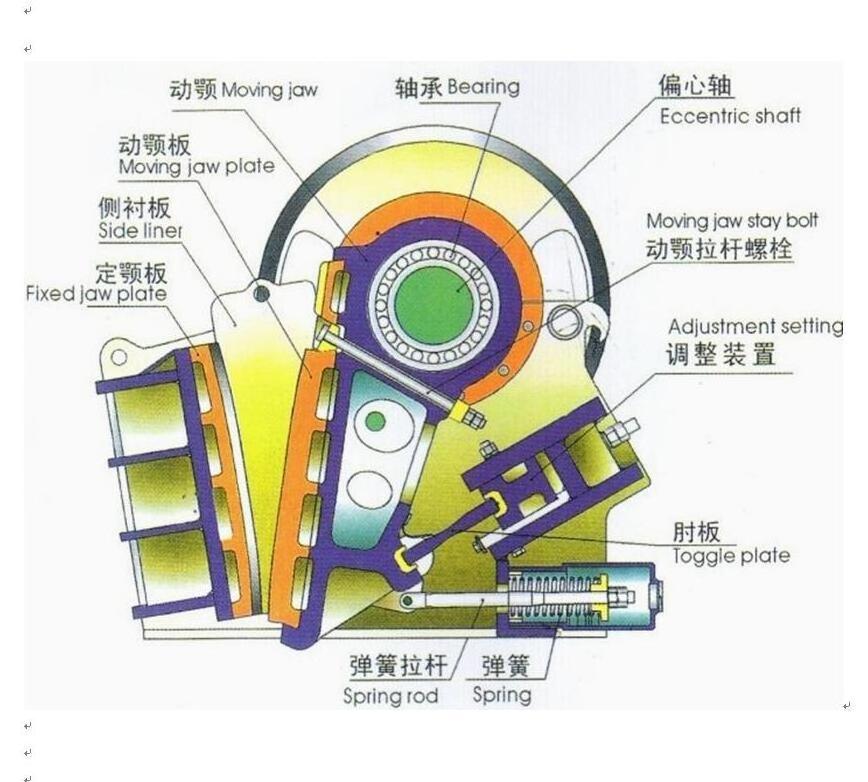

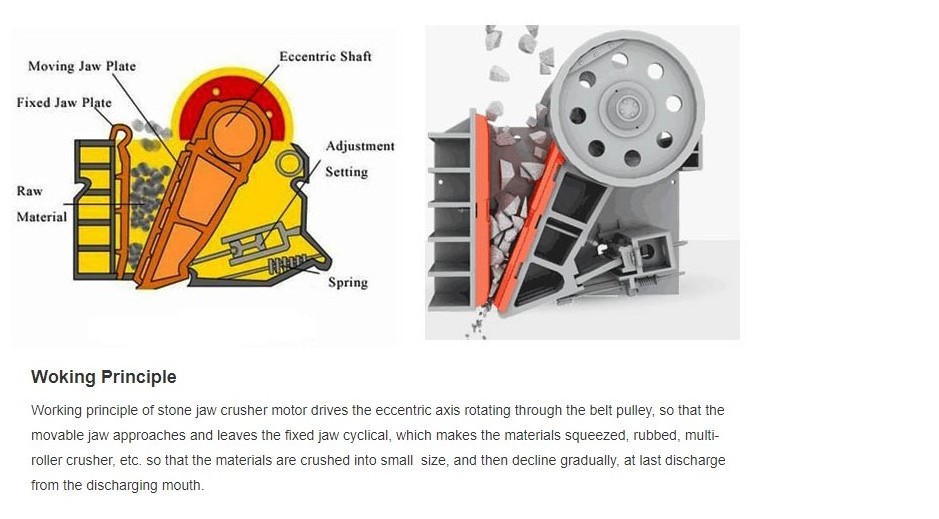

Working principle

The

electric motor

drives the belt and pulley to make the movable jaw move back and forth, up and down through the eccentric shaft. The raw material is squashed or split when movable jaw plate moves towards fixed jaw together with movable jaw. When movable jaw and movable jaw plate turn back by eccentric shaft and spring, the raw material, which is squashed or split before discharges from the bottom outlet under jaw plate. The bulk-production comes true while

electric motor

rotates continuously and the movable jaw crushes and discharges the raw material periodically.

Success Case

The Stone Crushing Plant mainly consists of Vibrating Feeder, Jaw Crusher, Cone Crusher or Impact Crusher, Vibrating Screen, Belt Conveyor and Control System, etc. It is completely capable to crush and screen limestone, marble, granite, basalt, river gravel and other hard stone materials, and produce sand & gravels with various granularity for construction and building industry. We are able to design and manufacture complete crusher plants with capacity from 30t/h to 500t/h, and to provide optimum and most economical solutions according to customers' requirements on stone specifications, output, application, etc.

Product Parameters

|

Model

|

Feed Size [mm]

|

Max. Feeding Size [mm]

|

Adjustable Size of Discharge Opening [mm]

|

Capacity [mm]

|

Power [kw]

|

Overall Dimension [mm]

|

Weight [t]

|

|

PE-150*250

|

150×250

|

125

|

10-40

|

1-3

|

5.5

|

670×820×760

|

0.81

|

|

PE-150*750

|

150×750

|

125

|

10-40

|

5-16

|

15

|

1050×1490×1055

|

3.8

|

|

PE-250*400

|

250×400

|

210

|

20-60

|

5-20

|

15

|

1160×1300×1240

|

2.8

|

|

PE-400*600

|

400×600

|

350

|

40-100

|

16-65

|

30

|

1480×1710×1646

|

7

|

|

PE-500*750

|

500×750

|

425

|

50-100

|

45-100

|

55

|

1800×1796×1940

|

12

|

|

PE-600*900

|

600×900

|

500

|

65-140

|

60-160

|

75

|

2235×2210×2380

|

17

|

|

PE-750*1060

|

750×1060

|

630

|

80-160

|

90-320

|

110

|

2430×2302×3110

|

29

|

|

PE-870*1060

|

870×1060

|

680

|

200-260

|

192-336

|

110

|

2551×2466×2770

|

29.2

|

|

PE-900*1200

|

900×1200

|

750

|

95-210

|

140-450

|

160

|

3789×2826×3025

|

50

|

|

PE-1000*1200

|

1000×1200

|

850

|

110-235

|

160-550

|

160

|

3889×2826×3025

|

57

|

|

PE-1200*1500

|

1200×1500

|

1020

|

150-300

|

400-800

|

185

|

4590×3342×3553

|

100.9

|

|

PEX-250*750

|

250×750

|

210

|

25-60

|

15-30

|

22

|

1750×1500×1420

|

5

|

|

PEX-250*1000

|

250×1000

|

210

|

25-60

|

16-52

|

37

|

1940×1650×1450

|

7

|

|

PEX-250*1200

|

250×1200

|

210

|

25-60

|

20-65

|

37-45

|

1940×1850×1450

|

8.7

|

|

PEX-350*750

|

350×750

|

280

|

30-80

|

16-55

|

30

|

1642×1882×1595

|

6.1

|

|

PEX-300*1300

|

300×1500

|

250

|

25-100

|

20-90

|

55

|

2285×2000×1720

|

11.6

|

Packing & Delivery

Hot Searches