- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CNPC-SS316L

-

Shape:

-

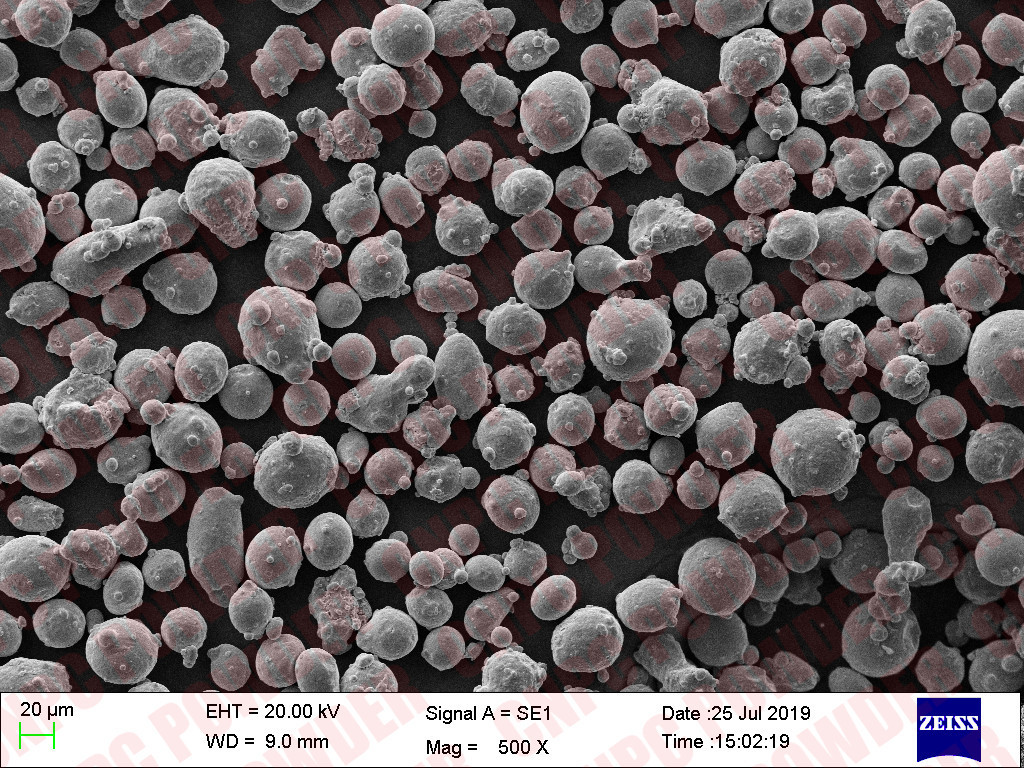

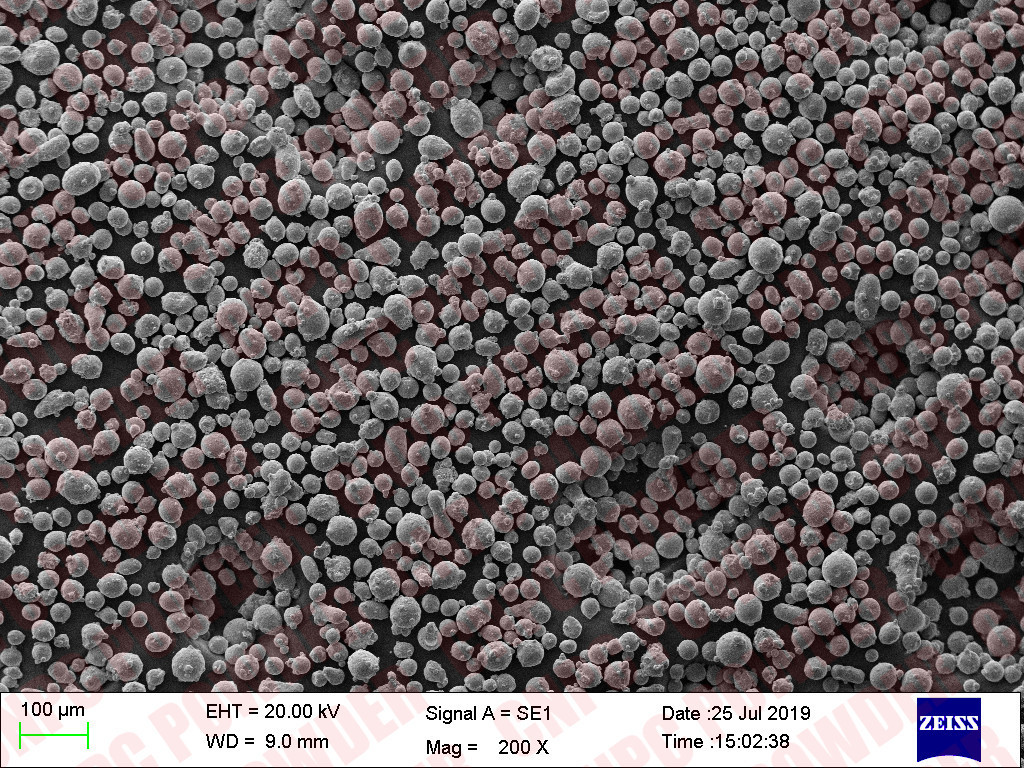

Spherical shape

-

Material:

-

SS316L

-

Chemical Composition:

-

Iron,Cr, Ni,Mo

-

MOQ:

-

1 Kg

-

Package:

-

Bag or Drum

-

Particle size:

-

0-25um,15-53um,45-105um

-

Color:

-

Grey

-

Form:

-

Powder

Quick Details

-

Application:

-

3D Printing

-

Place of Origin:

-

Anhui

-

Brand Name:

-

CNPCPOWDER

-

Model Number:

-

CNPC-SS316L

-

Shape:

-

Spherical shape

-

Material:

-

SS316L

-

Chemical Composition:

-

Iron,Cr, Ni,Mo

-

MOQ:

-

1 Kg

-

Package:

-

Bag or Drum

-

Particle size:

-

0-25um,15-53um,45-105um

-

Color:

-

Grey

-

Form:

-

Powder

Company Introduction

CNPC POWDER

©

headoffice is localed in Vancouver Canada and the facility is based in China, where they research, develop, market and manufacture their powdery materials.

CNPC POWDER

©

specializes in manufacturing and producing products such as Iron & Copper Alloy Powders, Nickel Powder, Stainless Steel Powder, 3D printing powder, Nano Particle Metal Alloy powder and other Metal Powders.

There are many uses for the different metal powders, some of which are powder metallurgy, 3D printer materials, welding, diamond tools, magnets and batteries. CNPC Metal powder are frequently used in different industries, such as the chemical, Electronics, Medical, Aerospace, Military Industry, and casting industry. All CNPC Powders are consistently produced at the highest quality possible. CNPC offers direct professional support and prompt responses.

There are many uses for the different metal powders, some of which are powder metallurgy, 3D printer materials, welding, diamond tools, magnets and batteries. CNPC Metal powder are frequently used in different industries, such as the chemical, Electronics, Medical, Aerospace, Military Industry, and casting industry. All CNPC Powders are consistently produced at the highest quality possible. CNPC offers direct professional support and prompt responses.

CNPC POWDER

©

has established business relationships with clients in more than 40 different countries across the world,including Middle East, South American and Europe, and maintains a very high reputation among them.

www.cnpcpowder.com

Experience

10+ years manufacturing experience.

Metal market advice and consulting.

Efficiency

Motivated staff & efficient structure.

A well-organized procurement process.

Growth

Worldwide developing opportunities

Low cost and high quatity control.

Product Description

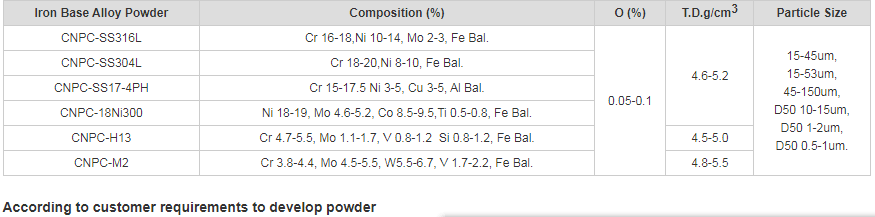

CNPC POWDER supply 3D printing metal powder include Iron Base Powder, Aluminum Base Powder, Nickel Base Powder, Titanium Base Powder, Cobalt Base etc ,which are widelyused in aerospace, molds, automotive, medical instruments etc.

Spherical shape with excellent fluidity, particle distribution between 0-25um,15-45um,15-53um 50-150um, the iron base alloy powder includes SS316L,SS304L,SS17-4PH,18Ni300,H13,M2 etc..

|

Product Name

|

Stainless Steel Powder SS316L

|

|

Apperance Density

|

4.6-5.2g/cm3

|

|

Particle Size

|

0-25um, 15-45um,15-53um,20-63um,45-105um,45-150um

|

|

Application

|

3D Printing

|

|

Standard

|

ISO9001:2008

|

Packing&Shipping

Storage Note:

The SS powder should be stored in a cool, dry, well ventilated warehouse and kept away from fire and other heat sources.

Relative humidity should remain below 75%.

The SS powder should be stored in a cool, dry, well ventilated warehouse and kept away from fire and other heat sources.

Relative humidity should remain below 75%.

The packing must be sealed, not to be affected with dampness . It should be kept apart from alkali, alcohol, and it should avoid mixed reservoir by all means. The storage area should be equipped with the right material in the case of leakage.

Manufacturing Technique

Gas atomized technique

First the coarse metarial or ingot is melted in the furnace to get liquid metal. Then the liquid metal is turned into droplets. Then we cool the liquid and collect the powder.Then sieve the powder and separate.We then collect the elaborate powder and mix them. At last we package the fashioned powder.

Gas Atomization---Cooling---Sieving---Mixing---Packaging

Gas Atomization---Cooling---Sieving---Mixing---Packaging

Water atomized technique

First the coarse metarial or ingot is melted in the furnace and we get liquid metal. Then use the atomizer with metal liquid to break it down into tiny droplets. Then drying and collecting the powder. We then use heat-treatment,then a furnace to dry the wet powder. Finally we sieve the powder.and mix them for packaging.

Water Atomization---drying---Heat treatment---Sieving---Mixing---packaging

Water Atomization---drying---Heat treatment---Sieving---Mixing---packaging

Reduced technique

Reduced Process First we use the chemical reduction method, single reduction and second reduction get the powder and then washing them and drying the sieving them.Then magnetic concentration and then mixing the filtered and packaging the fashioned powder.

Chemical Reduction---Washing---Drying---sieving---mixing---packaging

Chemical Reduction---Washing---Drying---sieving---mixing---packaging

Pulverizing technique

Pulverizing Method There are five methods we can sue to create metal power;Jaw crusher, Jet mill, Hammer Mill, Ball Mill

Agitating, Attriction Mill.

Agitating, Attriction Mill.

Elements analysis for ICP machine. Test material chemical content

O&N analysis machine

Test oxygen and nitrogen content

Lazer partilce size analysis machine

test powder particle size distribution.

Quality Control

C&S analysis machine for text carbon and sulfur conteny

Tap dansity machine

Appearnce density & flowability machine

Electron microscope for test partilce shape

Nitrogen & Argon gas

High precision balance

Our Services & Strength

Freight Cost Calculation

CNPC will calculate the freight costs of your powdery materials from Shanghai to your address. CNPC is able to provide customers with a discounted rate on shipping provided by our shipping rate accounts. Make your order today and contact us for the shipping cost!

CNPC will calculate the freight costs of your powdery materials from Shanghai to your address. CNPC is able to provide customers with a discounted rate on shipping provided by our shipping rate accounts. Make your order today and contact us for the shipping cost!

Powder Material Consultant

Do you need technical advice?

CNPC has 20+ years of experience in powder manufacturing process, this allows CNPC to answer any questions you have about powder materials.

Need Information on Importing Chemical Goods To Your Country? We are Client-oriented. Our.10 years of powder exporting experiences ensures that your purchase goes smoothly. Special packing materials are used to protect the powders from moisture and damage during transportation. CNPC keeps customers first at all times.

Do you need technical advice?

CNPC has 20+ years of experience in powder manufacturing process, this allows CNPC to answer any questions you have about powder materials.

Need Information on Importing Chemical Goods To Your Country? We are Client-oriented. Our.10 years of powder exporting experiences ensures that your purchase goes smoothly. Special packing materials are used to protect the powders from moisture and damage during transportation. CNPC keeps customers first at all times.

Hot Searches