- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Customer's Requirement

-

Weight:

-

4000 KG

-

Dimension(L*W*H):

-

Customizable

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Twin Screw Extruder Dog Food Pet Food Making Machine

-

Output:

-

Around 250-350kg/h

-

Diameter:

-

62.4mm

-

Screw Speed:

-

600r/min

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Haisi

-

Voltage:

-

Customer's Requirement

-

Power:

-

Customer's Requirement

-

Weight:

-

4000 KG

-

Dimension(L*W*H):

-

Customizable

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Twin Screw Extruder Dog Food Pet Food Making Machine

-

Output:

-

Around 250-350kg/h

-

Diameter:

-

62.4mm

-

Screw Speed:

-

600r/min

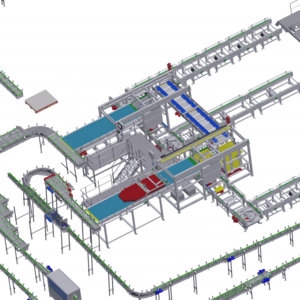

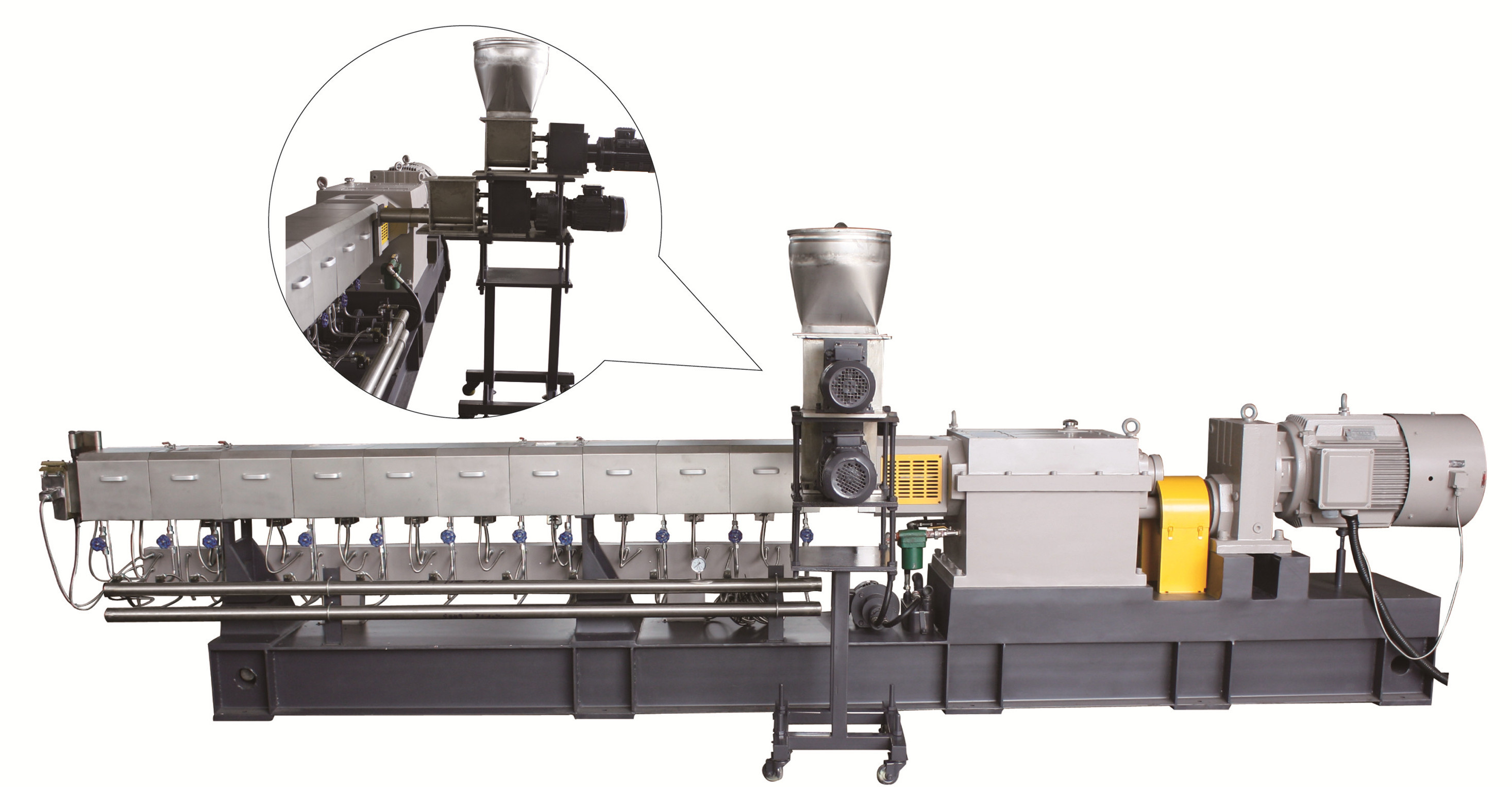

Side Feeding Twin Screw Pet Food Production Line

Nanjing Haisi Extrusion has many sophisticated technicals in producing dog food extruders with high-quality equipment and stable raw material suppliers, so we can provide excellent pet food for every consumer. Based on the superb produced dog food, the outstanding machine is an essential and important part of the production processes.

Our Dog food extruder can adjust to different materials with different ways as customers require.

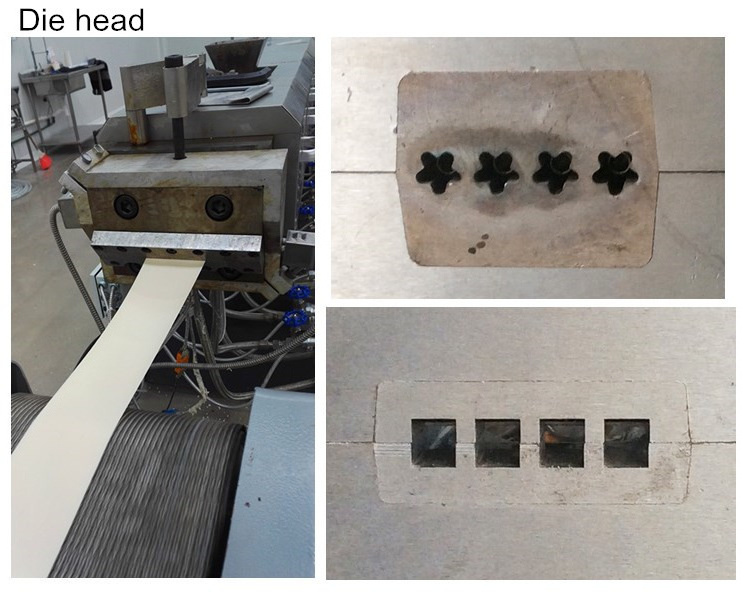

Dog food extruder pelletizing methods:

AIR COOLING STRAND PELLETIZING SYSTEM

AIR COOLING STRAND PELLETIZING SYSTEM

1. Special Design Dog Feed extruder diehead.

2. Dog food extruder with side feeder.

3. Air cooling belt conveyor for dog food extruder

The benefits of Dog Food Extruder :

It is a widespread and established technique in using dog food extrusion equipment in the pet supplies industry. There are some benefits of the production process below.

Fast-speed. The dog food extruder can run consistently with high-quality products and strict production deadlines. Our extruders are designed for fast, easy changeover and cleaning between runs.

Flexible. The dog food extruder is highly adaptable and suitable for a wide range of input materials. At the same time, the extruder can be extruded in various shapes, textures, and colors in different forms for final molding.

Consistent. The dog food extruder and cutting produces can produce a very homogeneous end product with constant cross-section and dimensions.

Efficient. The dog food extrusion process is cost-friendly, especially once conditions have been optimized. Precise process control and automation reduce raw material waste and increase production efficiency.

Dog food extruder running in customer’s factory

It is a widespread and established technique in using dog food extrusion equipment in the pet supplies industry. There are some benefits of the production process below.

Fast-speed. The dog food extruder can run consistently with high-quality products and strict production deadlines. Our extruders are designed for fast, easy changeover and cleaning between runs.

Flexible. The dog food extruder is highly adaptable and suitable for a wide range of input materials. At the same time, the extruder can be extruded in various shapes, textures, and colors in different forms for final molding.

Consistent. The dog food extruder and cutting produces can produce a very homogeneous end product with constant cross-section and dimensions.

Efficient. The dog food extrusion process is cost-friendly, especially once conditions have been optimized. Precise process control and automation reduce raw material waste and increase production efficiency.

Dog food extruder running in customer’s factory

Advantage of Haisi Extrusion Dog Food Extruder :

1. Production capacity: 100kg/h –400kg/h

2. Screw material: Food grade steel material

3. The barrel is equipped with alloy sleeve, rugged and durable.

4. NSK bearing, the gearbox is rugged and durable.

5. Gearbox is equipped with forced cooling filter system providing very good working condition.

6. Drived by Siemens Motor, Schneider electrical component, Delta brand Converter.

1. Production capacity: 100kg/h –400kg/h

2. Screw material: Food grade steel material

3. The barrel is equipped with alloy sleeve, rugged and durable.

4. NSK bearing, the gearbox is rugged and durable.

5. Gearbox is equipped with forced cooling filter system providing very good working condition.

6. Drived by Siemens Motor, Schneider electrical component, Delta brand Converter.

Technical Data of Dog Food Extruder:

|

Mode

|

Diameter

(mm)

|

L/D

|

Speed

(r/min)

|

Motor power

(kw)

|

Torque

(N.m)

|

Capacity

(kg/h)

|

|

TSE-50B

|

50.5

|

32-52

|

500

|

45-55

|

430

|

180-270

|

|

TSH-52B

|

51.5

|

32-60

|

600

|

90-132

|

682

|

270-400

|

|

TSE-65B

|

62.4

|

32-64

|

600

|

90

|

716

|

250-360

|

|

TSH-65B

|

62.4

|

32-64

|

600-800

|

110-160

|

875

|

350-500

|

|

TSE-75B

|

71

|

32-64

|

600

|

132

|

1050

|

350-500

|

|

TSH-75B

|

71

|

32-64

|

600-800

|

200-250

|

1365

|

600-800

|

Packing & Delivery

1. Be brushed anti-corrosive oil on screw barrel. 2. Packed with film. 3. Packed in the wooden.

Hot Searches